Raw Materials for Refractory:Rotary/Round/Shaft Kiln Calcined Bauxite 86 - Made in China for Low Price Refractory Applications

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DESCRIPTION

QUIKE DETAILS

| Place of Origin: | Henan, China (Mainland) | Shape: | Block , Powder | Material: | Bauxite |

| SiO2 Content (%): | 8% Max | Al2O3 Content (%): | 86%Min | Fe2O3 Content (%): | 2%Max |

| CaO Content (%): | CaO+MgO<0.6< span=""> | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | International standard |

| SiC Content (%): | International standard | Model Number: | 80# 85# 86# 87# | Brand Name: | CNBM |

SIZES

| GRAIN | normaly 0-1/1-3/3-5mm,or as per customers' request |

| POWDER | -200/-220/-325mesh,or as per customers' request |

OTHER GRADES OF RKB

GRADE | CHEMICAL CONTENT,% | PHYCICAL PROPERTIES | |||||

Al2O3,% | Fe2O3,% | TiO2,% | CaO+MgO,% | R2O,% | DENSITY, g/cm3 | WATER ABSORPTION,% | |

GAL-70 | ≥70 | ≤2.0 | - | ≤0.6 | ≤0.6 | ≥2.75 | ≤5.0 |

GAL-80 | ≥80 | ≤2.0 | ≤4.0 | ≤0.5 | ≤0.5 | ≥2.90 | ≤5.0 |

GAL-85 | ≥85 | ≤1.8 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.10 | ≤4.0 |

GAL-88 | ≥88 | ≤1.5 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.15 | ≤4.0 |

GAL-88HG | ≥88 | ≤1.5 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.25 | - |

PACKAGING & DELIVERY

| Packaging Details: | JUMBO BAGS/WOVEN BAGS/ PAPER BAGS (pallets) or as per customers' request! |

| Delivery Detail: | 25 days after buyer's instruction. |

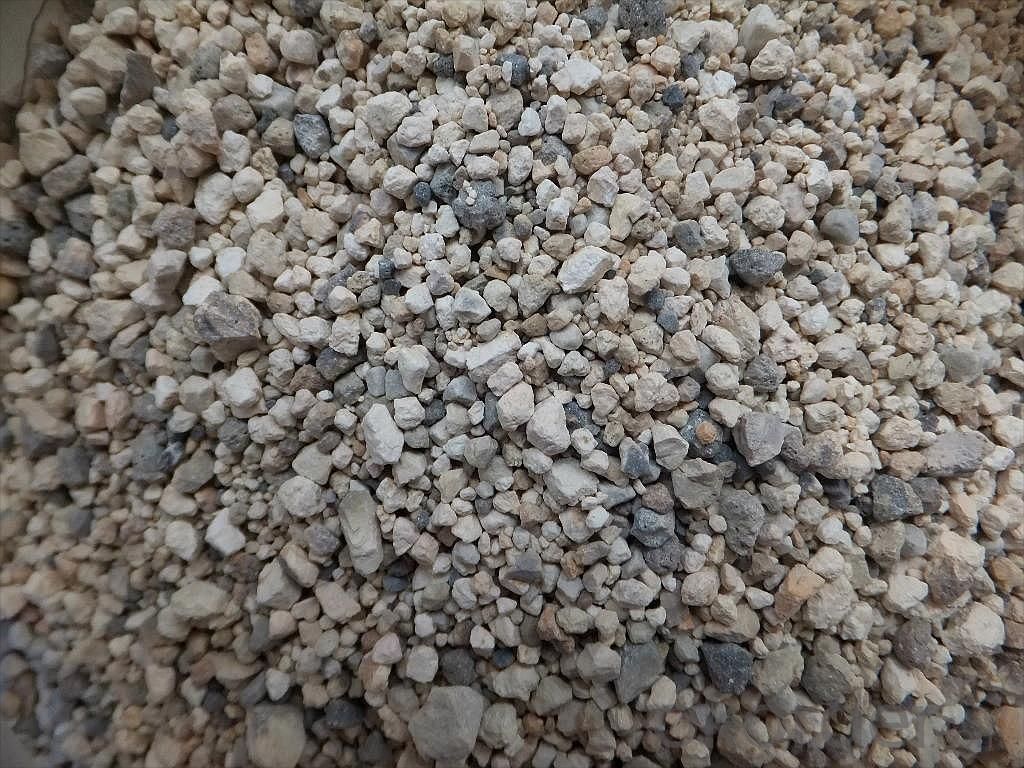

PICTURES

COMPANY PROFILE

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.

In line with the business, CNBM International launched E-business platform Okorder.com.

With the advantages in Cement, Composite Materials, New Building Materials and Engineering, we mainly concentrate on coal, steel and construction equipments and give priority to solar and wind energy development simultaneously utilizing our competitive position on traditional building materials to achieve sales revenue of RMB10 Billion in 2013.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

On July 7th, the US Fortune magazinepublishedthe 2014 Ranking List of World Top 500 Enterprises. China National Building Materials Group Corporation (CNBMGroup in short) enters into the Fortune Global 500 for the fourthsuccessive time withits operating revenue of 41.03 billion USD, ranking the 267th place, and rising 52 places over last year. Amongst the three building materials enterprises listed in the Fortune Global 500, CNBM ranks the second with promising momentum.

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

We promise the best cargo and the best service!

- Q: Can anyone tell me what is A-leve fireproof material?

- What you say is probably palstic! B-level means the fireproof rating is at B1-level because palstic material doesn't belong to fireproof materials. It only is fire?retardant. When wholesaling all kinds of insulation materials and construction, it need tos look at the names. B1-level refers to the fire endurance rating of the fireproof material, which is determined according to the fire resistance of the material. In addition, different parts of the material have different fire endurance ratings! You can download a "Specifications of Fireproof Design for Buildings" for further information!

- Q: How many types do refractory bricks have? Where the quality of refractory material is best? What is the model?

- Sinosteel Luoyang (Luoyang Refractory Material Plant in the past): High alumina(mainly blast furnace), Gongyi. There are also a series of high-tech materials (silicon carbide, carborundum, etc.) a major producer of high alumina; silicious: Resistant material for steel, glass furnace, cement kiln); magnesia. Divide from uses and divide from chemical texture; silicious(glass furnace): Xinmi, Hennan Province, Lengshui River, coke oven, etc.). As for the models, Yixing and Changxing in Jiangsu Province: Haicheng, Liaoning Province; silicious, I do not understand your intentions; magnesia (nonferrous, steel refining; magnesia: High alumina brick; Dashiqiao area! Please put it in detail.

- Q: what's the fireproof levels of fireproof and thermal inuslation matertial?

- What are the fireproof levels of fireproof and thermal inuslation matertial on the market? how to divide the fireproof levels of fireproof and thermal insulation material?

- Q: How to make use of waste refractory materials whose main elements are alumina and mullite?

- Crushing and pressing refractory bricks, or refractory parts . Such as welding positioner tracks use disposable tools.

- Q: Who knows which chrome refractories produced by the Henan refractory plant can be used for continuous casting?

- Chrome drainage sand can be used for coupling process there are many manufacturers do it, this is mainly a lot of chrome, chrome iron ore mainly refers to the drainage sand, adding ladle material amount regulator performance guide. Drainage sand as filling material of ladle bottom nozzle, one hand can be sintered at low temperature, to avoid joining the molten steel drainage sand floating accident, on the other hand, in the high temperature and long time refining steel surface can not meet the state of sintering is too thick, otherwise it will affect the automatic pouring rate, Hua Heng worth a try I'm not favored, my sky is the wind or rain rainbow you hate yourself in the manipulation of really useless emotional heart to still ache for breaking up before the sorry shuttle time in the moving picture of the clock in the opposite direction when the initial time begins to move back to love you

- Q: What are Grade-A waterproof inorganic thermal insulation materials?

- There is a market confusion in Grade-A waterproof inorganic thermal insulation materials. The products mainly include Grade-A monomer material like roc wool and ultra-thin insulation board and Grade-A composite material. Many Grade-B materials wraaped with calcium silicate board or foam cement belongs to Grade-A material, such as phenolic aldehyde composite. Some foamed materials with filling also belongs to Grade-A material. However, there are few products with Grade-A qualification. Many manufacturers are working on the margins of the records with Grade-A fireproofing performance examining report. But this situation will not be too long.

- Q: Can polystyrene foam color steel plate be used as decorative fireproofing material ?

- Polystyrene foam plastic can not be used as fireproofing material; polystyrene foam plastic is made up of polystyrene resin as main component, foaming?agent and other additives. It is a buffer material which is most widely used[1]. It is closed hole structure, so it has low water-absorbing quality and excellent water resistance; low density, about 0.015 ~0.03; good mechanical strength, excellent buffer?performance; good machinability, easy to be moulded; good dyeing property, thermal adaptability and anti-radiation; high dimensional accuracy, uniform structure. Therefore, it has a large share in external wall thermal insulation. But it will emit polluted styrene gas when burning. It is a kind of class B material in construction.

- Q: Could you tell me the fire-resisting time of class B fire proof door?

- The fire-resisting time of class B fire proof door is 1h and thickness of door can't be lower than 45mm.

- Q: How many levels are there in the classification of PP fireproof materials?

- PP fireproof materials level V-0: After two 10-second fame tests on the sample, the flame extinguishes within 30 seconds. Inflamer can not drop. V-1: After two 10-second flame tests on the sample, the flame extinguishes within 60 seconds. Inflamer can not drop. V-2: After two 10-second flame tests on the sample, the flame extinguishes within 60 seconds. Inflamer can drop.

- Q: What are grades of refractory materials?

- Refractories have lots of varieties which all have different purposes.1 divided according to the level of refractoriness: ordinary refractory materials: 1580 ℃ to 1770 ℃, advanced refractories: 1770 ℃ to 2000 ℃ and super refractories: above 2000 ℃ 2, divided in accordance with shapes and sizes : Standard ones: 230mm × 113mm × 65mm, no more than four ruler.

Send your message to us

Raw Materials for Refractory:Rotary/Round/Shaft Kiln Calcined Bauxite 86 - Made in China for Low Price Refractory Applications

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords