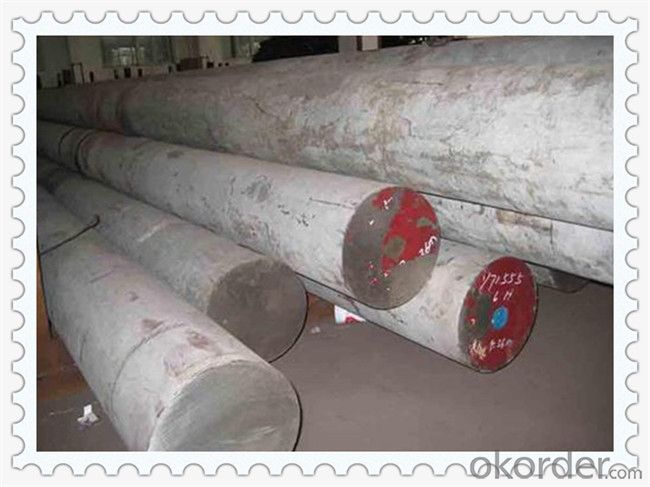

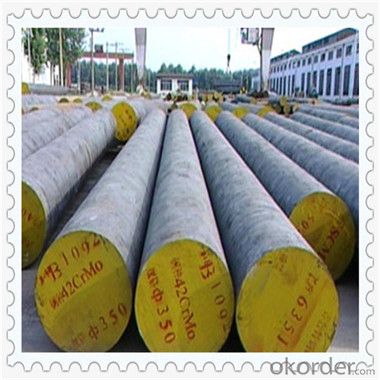

C45 SAE1045 Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Carbon Steel Round Bar C45 SAE1045 45#

| 1 | Product Name | SAE1020B,SAE1045B,S20CB, S55CB,C45 carbon structure steel round bar |

| 2 | Grade | 50#(SAE1050,1.1210,S50C) 45#(SAE1045,1.1191,S45C,CK45) |

| 3 | Specification | DIAMETER16~800MM, cutted any size by customer' requestments |

| 4 | Standard | ASTM,AISI,ASME,JIS,SUS,DIN,EN,GB,BS |

| 5 | Size | Round Steel:Diameter:50~300mm; Length:2000~7000mm Plate/Sheet Steel:Thickness:20-300mm; Width:200~3000mm; Length:2000~7000mm (We also can produce according to customer’s requirement) |

| 6 | Chemical composition | C=0.4~0.5,Si=0.2~0.3,Mn=0.6~0.7,P≤0.016,S≤0.008,Cr≤0.023,Ni≤0.014, Als≤0.005,Cu=0.018 |

| 7 | Packing | 1.surface polish 2. bundle package 3. wooden case ,wooden pallet package 4:container or bulk 5. special according to customer request

|

| 8 | Delivery | Normally according to the order quantity or upon negotiation |

| 9 | Price Item | EXW,FOB,CFR,CIF,DAF Or as negotiated |

10

| Application |

Used for making the mould bottom, plastic mould and normal machinery parts. |

| 11 | Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. |

- Q: What are the different types of corrosion-resistant steel round bars?

- There are several types of corrosion-resistant steel round bars available in the market, including stainless steel round bars (such as austenitic, ferritic, and martensitic stainless steel), duplex stainless steel round bars, and precipitation-hardening stainless steel round bars. These different types of steel round bars offer varying levels of corrosion resistance, strength, and other properties to suit different applications and environments.

- Q: How are steel round bars used in the manufacturing of heat exchangers?

- Steel round bars are commonly used in the manufacturing of heat exchangers due to their unique properties that make them suitable for this application. Heat exchangers are devices that transfer heat between two or more fluids, and steel round bars play a crucial role in their construction. One major use of steel round bars in heat exchangers is for the fabrication of the heat exchanger tubes. These tubes are responsible for carrying the fluids that need to be heated or cooled. Steel round bars are often used as the base material for these tubes due to their high strength and excellent heat transfer properties. The round shape of the bars allows for easy fabrication of the tubes, ensuring a tight and secure fit. Additionally, steel round bars are used to construct the headers and tube sheets of heat exchangers. The headers are the component that allows the fluid to enter and exit the heat exchanger, while the tube sheets hold the tubes in place. These components require high strength and durability to withstand the pressure and temperature differentials that occur during heat exchange. Steel round bars provide the necessary strength and stability to ensure the proper functioning of the heat exchanger. Furthermore, steel round bars are also used in the manufacturing of the support structures or frames of heat exchangers. These structures provide stability and support to the heat exchanger components and ensure proper alignment and positioning. Steel round bars offer excellent structural integrity and can withstand heavy loads, making them ideal for this purpose. In conclusion, steel round bars are an integral component in the manufacturing of heat exchangers. Their high strength, excellent heat transfer properties, and durability make them suitable for fabricating the tubes, headers, tube sheets, and support structures of heat exchangers. By utilizing steel round bars, manufacturers can ensure the efficiency, effectiveness, and longevity of heat exchangers in various industries, such as power generation, chemical processing, and HVAC systems.

- Q: What is the typical hardness of a steel round bar?

- The hardness of a steel round bar can vary depending on its specific grade and heat treatment. Generally, steel round bars have a hardness ranging from 100 to 300 on the Brinell hardness scale, which measures a material's resistance to indentation and is commonly used for assessing metal hardness. It's worth noting that different applications may call for varying levels of hardness, and steel round bars can be tailored to meet specific requirements through heat treatment processes like quenching and tempering.

- Q: What are the advantages of using nickel-titanium alloy steel round bars?

- There are several advantages of using nickel-titanium alloy steel round bars. Firstly, this alloy offers high strength and excellent corrosion resistance, making it suitable for various applications in industries such as aerospace, automotive, and medical. Additionally, nickel-titanium alloy steel has shape memory properties, allowing it to return to its original shape after deformation, making it ideal for applications requiring repeated bending or twisting. Furthermore, this alloy exhibits superelasticity, meaning it can withstand large amounts of strain without permanent deformation, providing enhanced durability and longevity. Overall, the unique combination of strength, corrosion resistance, shape memory, and superelasticity makes nickel-titanium alloy steel round bars a versatile and advantageous material choice.

- Q: Can steel round bars be used in the agricultural industry?

- Yes, steel round bars can be used in the agricultural industry. They are often used for constructing support structures such as fences, gates, and livestock pens. Steel round bars are also used in machinery and equipment manufacturing for applications like tractor attachments, irrigation systems, and grain storage bins. Their strength, durability, and versatility make them suitable for various agricultural purposes.

- Q: What are the advantages of using weather-resistant steel round bars?

- There are several advantages to using weather-resistant steel round bars. Firstly, weather-resistant steel round bars are designed to withstand the effects of harsh weather conditions. They are specifically formulated to resist corrosion, rust, and other forms of degradation caused by exposure to rain, snow, humidity, and even saltwater environments. This makes them highly suitable for outdoor applications, such as construction projects, marine structures, and infrastructure in coastal areas. Secondly, the use of weather-resistant steel round bars eliminates the need for additional protective coatings or treatments. Unlike regular steel, which requires regular maintenance and painting to prevent rust and corrosion, weather-resistant steel round bars possess a natural protective layer that forms on the surface, known as patina. This patina acts as a barrier against further corrosion, reducing the overall maintenance requirements and extending the lifespan of the material. Thirdly, weather-resistant steel round bars offer exceptional strength and durability. They are manufactured using a special alloy composition, which enhances their mechanical properties and makes them highly resistant to impact, bending, and fatigue. This makes them ideal for structural applications where strength and reliability are crucial, such as in bridges, building frameworks, and heavy machinery. Additionally, weather-resistant steel round bars have aesthetic advantages. The unique patina that develops on the surface of these bars gives them a distinctive appearance, often described as an attractive and warm reddish-brown color. This natural weathered look can be desirable for architectural and design purposes, adding a visually appealing element to structures and outdoor installations. Lastly, the use of weather-resistant steel round bars contributes to sustainability and cost-effectiveness. Due to their long lifespan and low maintenance requirements, these bars offer a more sustainable solution compared to traditional steel, which often requires frequent painting and replacement. Furthermore, the initial investment in weather-resistant steel round bars may be higher than regular steel, but the long-term savings in maintenance and replacement costs make them a cost-effective choice in the long run. In conclusion, the advantages of using weather-resistant steel round bars include their ability to withstand harsh weather conditions, eliminate the need for additional protective coatings, provide exceptional strength and durability, offer aesthetic appeal, and contribute to sustainability and cost-effectiveness.

- Q: What is the hardness of a steel round bar?

- The hardness of a steel round bar can vary depending on the specific type of steel used and the manufacturing process, but it is typically measured on the Rockwell or Brinell hardness scales.

- Q: What are the advantages of using magnesium-alloy steel round bars?

- One advantage of using magnesium-alloy steel round bars is their high strength-to-weight ratio. These bars offer excellent strength and durability while being lightweight, making them suitable for applications where weight reduction is crucial, such as in aerospace and automotive industries. Furthermore, magnesium-alloy steel round bars exhibit good corrosion resistance, which extends their lifespan and makes them ideal for outdoor and marine applications. Additionally, these bars can be easily machined and formed, allowing for flexibility in design and fabrication processes.

- Q: Can steel round bars be used in the manufacturing of machinery?

- Certainly, machinery manufacturing can make effective use of steel round bars. Various industries commonly employ steel round bars due to their robustness, longevity, and adaptability. These bars frequently serve in the fabrication of essential components like shafts, axles, gears, and other mechanical parts that necessitate exceptional strength and resistance against deterioration. Notably, steel round bars exhibit remarkable mechanical properties, encompassing impressive tensile strength and superior machinability, rendering them highly suitable for heavy-duty machinery and equipment. Furthermore, steel round bars can be conveniently welded, forged, or machined into the desired configuration, thus establishing them as a preferred option for machinery manufacturing.

- Q: Can steel round bars be used for making valves or fittings?

- Yes, steel round bars can be used for making valves or fittings. Steel round bars offer excellent strength, durability, and corrosion resistance, making them suitable for various applications in the manufacturing of valves and fittings. They can be easily machined, welded, and fabricated to meet specific design requirements, ensuring reliable and long-lasting performance in valve and fitting systems.

Send your message to us

C45 SAE1045 Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords