Sea 9260 Spring Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sea 9260 Spring Steel Bar

Specification

1, Diameter: 8mm-250mm rounds

5mm-9mm rods

2, Length: 2m, 3m, 5.8m, 6m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black, Polished, Galvanized

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition (%)

| C | Si | Mn | S | P | Cr | Ni | Cu |

| 0.52-0.60 | 1.50-2.00 | 0.60-0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.20 |

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

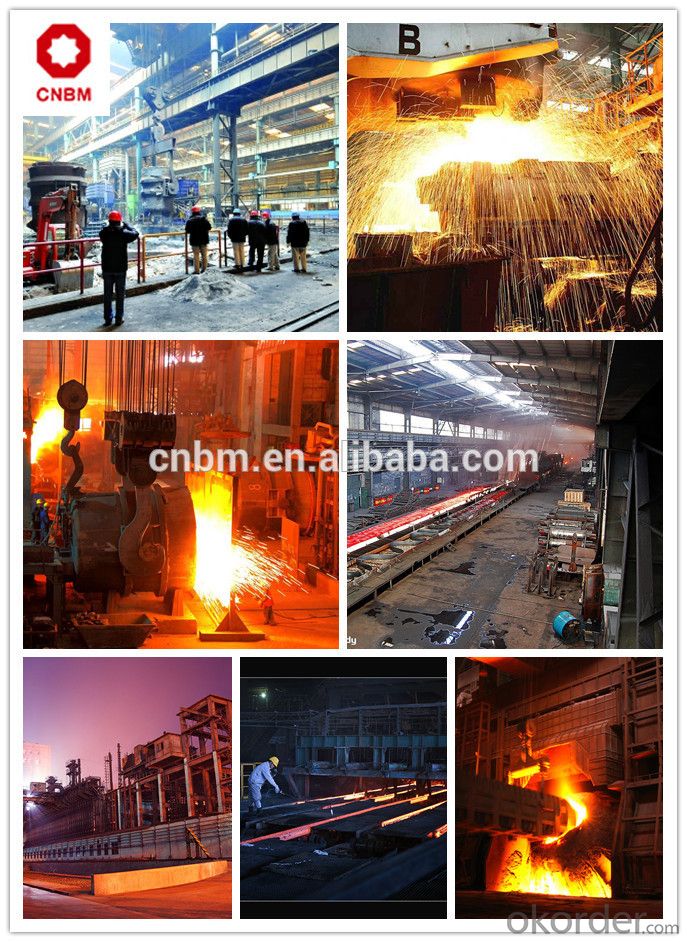

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: Are steel round bars susceptible to cracking?

- Yes, steel round bars can be susceptible to cracking under certain conditions. The specific factors that can contribute to cracking in steel round bars include high stress levels, improper heat treatment, and the presence of impurities or defects in the material. Additionally, sudden changes in temperature or excessive loading can also increase the likelihood of cracking. It is important to note that steel round bars can vary in their susceptibility to cracking depending on the specific grade and composition of the steel. Some types of steel, such as low carbon or mild steel, are generally less prone to cracking compared to higher carbon or alloy steels. To mitigate the risk of cracking, proper handling and storage of steel round bars is crucial. This includes avoiding dropping or mishandling the bars, as well as storing them in a dry and controlled environment to prevent corrosion. Furthermore, proper heat treatment processes, such as annealing or tempering, can help improve the structural integrity of steel round bars and reduce the risk of cracking. Additionally, regular inspections and testing for any potential defects or impurities can help identify and address any issues before they lead to cracking. Overall, while steel round bars can be susceptible to cracking, taking appropriate precautions and utilizing proper manufacturing and handling techniques can minimize the risk and ensure the integrity of the bars.

- Q: What are the different grades of stainless steel round bars?

- There are several grades of stainless steel round bars, with the most common ones being 304, 316, and 410. These grades differ in their chemical composition, strength, and corrosion resistance properties, making them suitable for various applications in different industries.

- Q: What are the different types of steel round bar surface defects?

- There are several different types of surface defects that can occur on steel round bars. Some of the most common defects include: 1. Scale: This is a thin layer of oxide that forms on the surface of the steel during the manufacturing process. It appears as a rough, flaky or scaly texture and can be easily removed by pickling or abrasive cleaning. 2. Pitting: Pitting is a localized corrosion that appears as small, shallow holes or depressions on the surface of the steel. It is typically caused by exposure to corrosive substances or environments and can weaken the material if left untreated. 3. Surface cracks: These are small, visible cracks that appear on the surface of the steel round bar. They can be caused by various factors such as improper cooling during the manufacturing process, excessive stress, or improper handling. Surface cracks can reduce the structural integrity of the steel and should be carefully inspected and repaired if necessary. 4. Decarburization: This defect occurs when the surface layer of the steel loses its carbon content, leading to reduced hardness and strength. Decarburization is often caused by high temperatures during heat treatment or improper cooling methods. It can be detected through visual inspection or by conducting hardness tests. 5. Lamination: Lamination defects occur when there are layers or flakes within the steel round bar. These layers can cause weakness in the material and compromise its structural integrity. Lamination defects are typically caused by improper rolling or excessive impurities in the steel. 6. Inclusions: Inclusions are foreign materials or impurities that are trapped within the steel during the manufacturing process. They can appear as dark spots, streaks, or irregular shapes on the surface of the round bar. Inclusions can reduce the strength and ductility of the steel and can be caused by factors such as improper raw material quality or inadequate refining processes. It is important to note that surface defects in steel round bars can vary in severity and impact on the material's performance. Regular inspection and quality control measures are essential to identify and rectify any surface defects to ensure the integrity and reliability of the steel round bar.

- Q: Can steel round bars be used in the manufacturing industry?

- Yes, steel round bars can be used in the manufacturing industry. Steel round bars are versatile and widely used in various manufacturing processes. They can be used for machining, forging, welding, and fabrication to create a wide range of products such as machinery parts, tools, automotive components, construction materials, and more. Steel round bars offer high strength, durability, and excellent resistance to wear, making them suitable for demanding manufacturing applications. Additionally, steel round bars are available in different grades and sizes, allowing manufacturers to choose the most suitable option for their specific requirements.

- Q: Can steel round bars be used in the production of musical equipment?

- Yes, steel round bars can be used in the production of musical equipment. They can be utilized to create various components such as structural frames, supports, or even as part of the instrument itself. Steel is a versatile material known for its strength and durability, making it suitable for applications in the manufacturing of musical instruments.

- Q: Can steel round bars be used for making security grilles?

- Yes, steel round bars can be used for making security grilles. The strength and durability of steel make it an excellent choice for security applications, providing protection and ensuring the safety of premises.

- Q: What is the tolerance for diameter and length of steel round bars?

- The tolerance for diameter and length of steel round bars can vary depending on the specific industry standards and requirements. In general, tolerances for diameter are typically specified in terms of a plus or minus deviation from the nominal diameter. For example, a tolerance of +/- 0.005 inches means that the actual diameter of the steel round bar can vary by up to 0.005 inches from the nominal diameter. Similarly, tolerances for length are also specified in terms of a plus or minus deviation from the nominal length. These tolerances can be expressed as a percentage or an absolute value. For instance, a tolerance of +/- 1% or +/- 0.5 inches means that the actual length of the steel round bar can vary by up to 1% of the nominal length or 0.5 inches, whichever is greater. It is important to note that different industries may have different tolerance requirements based on the specific applications and intended use of the steel round bars. Therefore, it is crucial to refer to the applicable industry standards or consult with the manufacturer or supplier to determine the exact tolerance specifications for diameter and length of steel round bars in a particular context.

- Q: What is the diameter deviation of 12 mm galvanized round bar?

- The allowable deviation of dia 12 is + 0.3mm. The name of this specification is: GB1499.1-2008, reinforced concrete, steel, first parts: hot rolled round steel bar, on the third page of the book.

- Q: Can steel round bars be used for making wheel hubs?

- Yes, steel round bars can be used for making wheel hubs. Steel is a common material choice for wheel hubs due to its high strength and durability, making it suitable for withstanding the forces and pressures experienced by wheel hubs during operation.

- Q: Can steel round bars be used for making bridges?

- Yes, steel round bars can be used for making bridges. Steel is a commonly used material in bridge construction due to its high strength and durability. Round bars, also known as reinforcing bars or rebars, are often used to reinforce concrete structures, including bridge decks and piers. They provide additional tensile strength and help to distribute loads more evenly, making the bridge more resistant to bending or twisting forces. Additionally, round bars can be used as structural elements in the construction of cable-stayed or suspension bridges, where they are used to support and strengthen the main load-bearing cables. Overall, steel round bars are a versatile and reliable choice for bridge construction, offering the necessary strength and stability required to withstand the heavy loads and harsh environmental conditions experienced by bridges.

Send your message to us

Sea 9260 Spring Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords