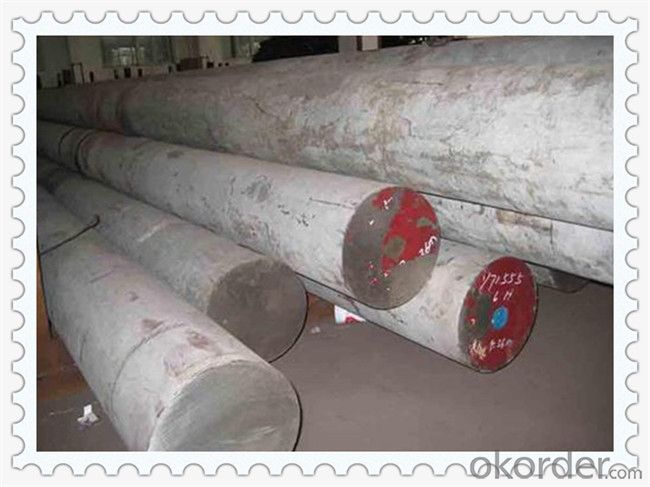

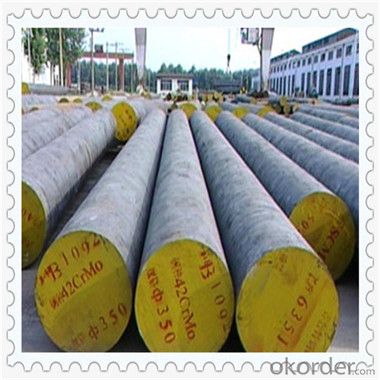

Carbon Steel Round Bar C45 SAE1045

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Carbon Steel Round Bar C45 SAE1045 45#

| 1 | Product Name | SAE1020B,SAE1045B,S20CB, S55CB,C45 carbon structure steel round bar |

| 2 | Grade | 50#(SAE1050,1.1210,S50C) 45#(SAE1045,1.1191,S45C,CK45) |

| 3 | Specification | DIAMETER16~800MM, cutted any size by customer' requestments |

| 4 | Standard | ASTM,AISI,ASME,JIS,SUS,DIN,EN,GB,BS |

| 5 | Size | Round Steel:Diameter:50~300mm; Length:2000~7000mm Plate/Sheet Steel:Thickness:20-300mm; Width:200~3000mm; Length:2000~7000mm (We also can produce according to customer’s requirement) |

| 6 | Chemical composition | C=0.4~0.5,Si=0.2~0.3,Mn=0.6~0.7,P≤0.016,S≤0.008,Cr≤0.023,Ni≤0.014, Als≤0.005,Cu=0.018 |

| 7 | Packing | 1.surface polish 2. bundle package 3. wooden case ,wooden pallet package 4:container or bulk 5. special according to customer request

|

| 8 | Delivery | Normally according to the order quantity or upon negotiation |

| 9 | Price Item | EXW,FOB,CFR,CIF,DAF Or as negotiated |

10

| Application |

Used for making the mould bottom, plastic mould and normal machinery parts. |

| 11 | Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. |

- Q: Are steel round bars available in different colors?

- No, steel round bars are typically available in a silver or gray color as they are made from alloyed iron and carbon.

- Q: What are the advantages of using nickel-chromium-manganese alloy steel round bars?

- The advantages of using nickel-chromium-manganese alloy steel round bars include their excellent strength and durability, high resistance to corrosion and oxidation, good machinability, and the ability to withstand high temperatures and pressures. Additionally, this alloy offers good weldability and can be easily formed into various shapes and sizes, making it suitable for a wide range of applications in industries such as aerospace, automotive, and construction.

- Q: What is the maximum load capacity of a steel round bar?

- The maximum load capacity of a steel round bar depends on various factors such as its diameter, length, and composition. It is typically determined by conducting tests and calculations based on the specific properties and intended use of the bar.

- Q: How do you prevent rusting of steel round bars?

- To prevent rusting of steel round bars, there are several effective measures that can be taken: 1. Apply a protective coating: One of the most common ways to prevent rusting is by applying a protective coating on the steel round bars. This can be done by using paint, varnish, or a specialized rust-preventive coating. The coating acts as a barrier between the steel surface and the surrounding environment, preventing moisture and oxygen from reaching the metal and causing rust. 2. Keep the steel dry: Moisture is a key factor that contributes to the corrosion of steel. Therefore, it is crucial to keep the steel round bars as dry as possible. This can be achieved by storing them in a dry environment or using dehumidifiers in areas where moisture levels are high. 3. Maintain proper ventilation: Adequate ventilation helps in preventing the accumulation of moisture around the steel round bars. Good air circulation allows any moisture that may be present to evaporate, reducing the risk of rust formation. 4. Implement a rust inhibitor: Rust inhibitors, also known as corrosion inhibitors, can be applied to the steel round bars to prevent rust formation. These inhibitors work by chemically reacting with the metal surface, forming a protective layer that inhibits the oxidation process. Rust inhibitors can be in the form of oils, waxes, or specialized compounds. 5. Store in a controlled environment: If the steel round bars are not immediately being used, it is essential to store them in a controlled environment. This typically means keeping them in a dry, temperature-controlled area to minimize exposure to moisture and extreme temperatures, both of which can accelerate rust formation. 6. Regular maintenance and inspection: It is advisable to regularly inspect the steel round bars for signs of rust or damage. If any rust spots are detected, they should be promptly cleaned and treated with a rust remover or inhibitor to prevent further corrosion. By following these preventive measures, the rusting of steel round bars can be significantly reduced, ensuring their longevity and maintaining their structural integrity.

- Q: How do steel round bars compare to aluminum or steel tubing?

- Steel round bars, aluminum tubing, and steel tubing all have their own unique properties and advantages. Steel round bars are known for their high strength and durability, making them suitable for applications that require heavy loads or high-stress conditions. Aluminum tubing, on the other hand, is lightweight and corrosion-resistant, making it ideal for projects that prioritize weight reduction and resistance to environmental elements. Steel tubing offers a balance between strength and weight, making it a versatile choice for various industrial applications. Ultimately, the choice between steel round bars, aluminum tubing, or steel tubing depends on the specific requirements of the project, such as load-bearing capacity, weight limitations, and environmental factors.

- Q: What are the different surface defects that can occur in steel round bars?

- There are several different surface defects that can occur in steel round bars. These defects can be classified into various categories based on their appearance and severity. Some of the common surface defects include: 1. Scale: Scale is a thin layer of oxide that forms on the surface of steel during the manufacturing process. It appears as a rough, flaky coating and can be easily removed by mechanical means. 2. Pits: Pits are small depressions or craters that can occur on the surface of the steel. They are usually caused by corrosion or mechanical damage. Pits can weaken the structural integrity of the steel and may require repair or replacement. 3. Scratches: Scratches are shallow grooves or cuts on the surface of the steel. They can be caused by handling, transportation, or machining processes. While minor scratches may not affect the performance of the steel, deep scratches can lead to stress concentration and potential failure. 4. Roll marks: Roll marks are raised or depressed lines or patterns that are left on the surface of the steel during the rolling process. These marks are typically caused by the uneven pressure distribution between the rolls and can affect the dimensional accuracy and surface quality of the steel. 5. Laminations: Laminations are thin layers or bands of non-metallic inclusions that can occur parallel to the surface of the steel. They are usually caused by inadequate refining or improper casting techniques. Laminations can decrease the strength and toughness of the steel and may require further processing or rejection. 6. Decarburization: Decarburization refers to the loss of carbon content on the surface of the steel. It can occur during heating, annealing, or hot working processes. Decarburization can reduce the hardness and strength of the steel and may lead to premature failure under load. 7. Surface cracks: Surface cracks are visible cracks that occur on the surface of the steel. They can be caused by excessive cooling rates, improper heat treatment, or mechanical stress. Surface cracks can compromise the structural integrity of the steel and may require repairs or rejection. These are just a few examples of the different surface defects that can occur in steel round bars. It is essential to inspect and address these defects to ensure the quality and performance of the steel in various applications.

- Q: The difference between round steel and screw steel

- The difference between round bar and round bar is that the surface has longitudinal ribs and transverse ribs, usually with two longitudinal ribs and transverse ribs uniformly distributed along the length direction. The rebar is a kind of small section steel, mainly used for the skeleton of reinforced concrete construction members. In use, some mechanical strength, bending deformation property and welding performance are required. The raw steel billet for the production of threaded steel is carbon structural steel or low alloy structural steel which is treated by calm melting, and the finished steel bar is delivered in hot rolling forming, normalizing or hot rolling state.

- Q: How do steel round bars compare to stainless steel round bars?

- Steel round bars and stainless steel round bars differ in terms of their composition and properties. Steel round bars are made of carbon steel, which contains varying amounts of carbon and other alloys. They are generally more affordable and widely available, but may be susceptible to corrosion. On the other hand, stainless steel round bars are made of an alloy that contains a higher percentage of chromium. This addition of chromium enhances the corrosion resistance of stainless steel, making it suitable for applications in environments with high moisture or exposure to chemicals. Although stainless steel round bars may be more expensive, they offer superior durability and a polished appearance. Overall, the choice between steel and stainless steel round bars depends on the specific requirements of the application, such as strength, corrosion resistance, and cost-effectiveness.

- Q: Can steel round bars be used in the pharmaceutical industry?

- It is possible to use steel round bars in the pharmaceutical industry. Steel round bars are widely used in different sectors, including pharmaceuticals, because of their strength, durability, and versatility. In the pharmaceutical field, steel round bars can be applied for various purposes, such as producing equipment, machinery, and storage systems. These bars can be utilized to create pharmaceutical manufacturing equipment like mixers, reactors, and centrifuges, which necessitate robust and dependable materials to ensure effectiveness and safety in the production processes. Additionally, steel round bars can be employed in constructing storage systems like racks and shelves, providing a solid and secure solution for organizing pharmaceutical products and supplies. The corrosion resistance and ease of cleaning of steel make it appropriate for maintaining hygienic conditions in pharmaceutical facilities. Overall, steel round bars give the pharmaceutical industry a dependable and cost-effective material choice for diverse applications.

- Q: Can steel round bars be used for making body panels?

- No, steel round bars are not typically used for making body panels. Body panels are usually made from sheet metal or aluminum, as they offer better flexibility, ease of shaping, and weight reduction compared to steel round bars.

Send your message to us

Carbon Steel Round Bar C45 SAE1045

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords