Bulk Packaging Tape with Double Sided Tissue DSW-80H Water Based Acrylic 110 Micron - All Color Available

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

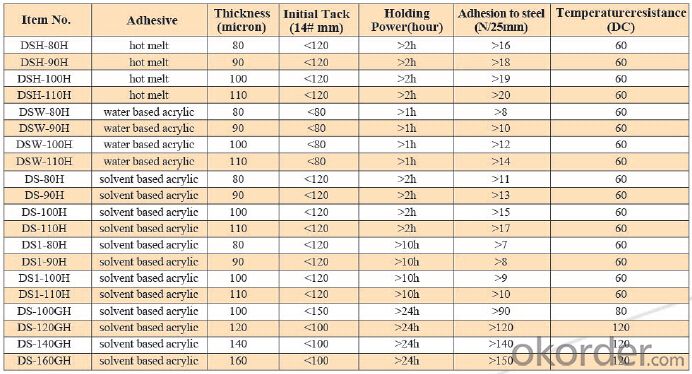

Typical Physical Reports of Double Sided Tissue Tape

Description

The Double Sided Tissue Tape is of tissue as the carrier, coating with hot melt adhesive, water based acrylic, solvent based acrylic. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

Application

General purpose of Double Sided Tissue Tape: widely used for bonding, fixing for leather, foam, sponge, garment, shoe, luggage, plastic, paper splicing and stationery.

Packaging & Delivery

Packaging Detail:

Log Roll: Length 1000mm; width: 1050mm, 1260mm, 1040mm..

Cut Roll: As per customer’s requirements

Delivery Detail: within 7-15 working days after receiving your deposit

Service

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service

Well-trained & experienced sales representative are ready to answer you.

About us

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Welcome to contact us and visit the factory!

- Q: 2014, how can I sell the tape better?

- Second, your after-sales service can do what extent, can be exchanged or can not sell, you can return, this should be explained in detail, this is very important for customers,Third, your personal image, must give people a good impression, don't speak slow, simple, but not to sell the tape as the theme, you are going to help customers find a good product, because you give customers a profitable product, you do not help him, you just the customer is a friend, not God, to treat him as a friend, to be sincere,

- Q: Belt business is a big profit

- The use of a large amount of market potential, is ideal for the laid-off unemployed, second occupation and three industrial investment and set up factories.As everyone knows, tape product market sales, high profit, brand demand is not high, but because of the production equipment investment is too large to produce user feel weak, small investment can not intervene. With the continuous development of China's economy, especially the rapid development of the packaging industry in recent years, the market of the tape demand is huge. Based on our technical staff on the investigation, combined with the domestic and foreign advanced technology, the bold exploration and innovation, developed a multifunctional energy-saving tape production equipment of various specifications of success. The series of indicators is much higher than that of the old production equipment. The equipment, reliable performance, convenient operation, energy saving, low cost, no noise. The tape produced with high strength, high gloss, good sealing, no pollution, so that the majority of users to achieve the dream. The founder of tape with low cost, the scale of the students The desire of the factory has been well received by the industry and people from all walks of life

- Q: Can packaging tape be used for sealing recreational or outdoor gear?

- Indeed, recreational or outdoor gear can indeed be sealed using packaging tape. The primary purpose of packaging tape is to securely seal packages and boxes, guaranteeing a robust and enduring seal. When it comes to repairing tears or holes in gear such as tents, sleeping bags, backpacks, or tarps, packaging tape can serve as a viable solution. It can also reinforce weak points or seams in gear, effectively adding extra strength and protection. Nevertheless, it is crucial to bear in mind that although packaging tape can provide a temporary fix, it may not possess the same longevity or weather resistance as specialized outdoor repair tapes. Consequently, it is always advisable to opt for the appropriate gear repair products, as they offer a more reliable and enduring solution.

- Q: Is packaging tape easy to tear by hand?

- Yes, packaging tape is generally easy to tear by hand.

- Q: Is packaging tape resistant to tearing or ripping?

- Packaging tape, in general, displays resistance to tearing or ripping. Its purpose is to establish a robust and reliable seal on packages, guaranteeing their preservation during transportation or manipulation. Packaging tape consists of sturdy substances like polypropylene or reinforced paper, which provide considerable tensile strength and resistance against tearing. Moreover, numerous packaging tapes possess adhesive characteristics that augment their resistance to tearing or ripping. Nevertheless, it is crucial to acknowledge that the strength and tear resistance of packaging tape can differ based on the particular brand or type of tape employed.

- Q: Can packaging tape be used for sealing plastic storage baskets?

- Yes, packaging tape can be used for sealing plastic storage baskets. It provides a secure and durable seal to keep items inside the basket protected and organized.

- Q: Can packaging tape be used for sealing office supplies or stationery?

- Yes, packaging tape can certainly be used for sealing office supplies or stationery. It is a versatile adhesive tape that is commonly used for sealing boxes and packages. However, when using packaging tape for sealing smaller items like office supplies or stationery, it is important to consider the size and weight of the item. If the item is lightweight and the packaging tape is not too wide or bulky, it can be a convenient and effective option for sealing. However, for smaller items, it may be more suitable to use other types of tape, such as clear tape or double-sided tape, which are specifically designed for sealing stationery and office supplies.

- Q: Does packaging tape come in different widths for different applications?

- Yes, packaging tape does come in different widths for different applications. Packaging tape is available in various widths ranging from as small as 0.75 inches to as wide as 3 inches or even more. The choice of width depends on the specific application and the size of the package being sealed. Smaller widths are often used for lighter weight packages or for sealing small boxes or envelopes. On the other hand, wider widths are commonly used for heavy-duty or larger boxes that require extra strength and security. The availability of different widths allows users to select the most appropriate tape size based on their specific packaging needs.

- Q: Buy adhesive tape every time, discover its sticky viscosity is insufficient, encounter cold weather, do not use well,

- Adhesive tape testing methods are mainly1, tack: the test tape is stuck to the initial ability of the adherend size, general method is to use the standard ball into the natural roll tape 45 degree angle on the tilt, increasing the size of the ball, the ball can stick to the greater, the greater initial viscosity

- Q: How does packaging tape perform on porous surfaces?

- When it comes to porous surfaces, packaging tape shows decent performance, even though its adhesive strength might be slightly compromised compared to non-porous surfaces. This tape is specifically designed to stick to a variety of surfaces such as cardboard, paper, and fabric, all of which are commonly known as porous materials. However, because these surfaces are porous, some of the adhesive may seep into the material, resulting in a reduction in bond strength. Moreover, the tape may not stick as firmly to porous surfaces, which makes it more likely to peel or lift. To ensure maximum adhesion, it is recommended to make sure the surface is clean and dry before applying the tape.

Send your message to us

Bulk Packaging Tape with Double Sided Tissue DSW-80H Water Based Acrylic 110 Micron - All Color Available

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords