Building Lifter SC200/200 Hot Galvanizing Processing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of SC200/200 Building Lifter Description

To serve the increasing demand for highrise construction, we developed the high speed VF hoist, with a max.lifting speed of 96 m/min.

It has the following structure:

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the energy consumption and mitigates effects to on site electric equipments.

4. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack,pinion and the brake and prolongs the spare parts'life.

5. The VF system also has the over voltage protection, low voltage protection, overcurrent, overload and anti-stalling protection functions.

6. The System applies the special software for hoists developed by our company, making the operation more safe and reliable.

Main Features of SC200/200 Building Lifter

1. The recomended cage dimension(L*W*H)(m): 2.0*1.0*2.5, 2.5*1.0*2.5, 2.5*1.3*2.5, 3.0*1.5*2,5, 3.2*1.5*2.5, 3.8*1.5*2.5, 4.0*1.5*2.5, 4.2*1.5*2.5 etc. We can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to yout requirements.

3. The mast section and the tie-in surface can adopt paint-spray, or hot galvanizing processing.

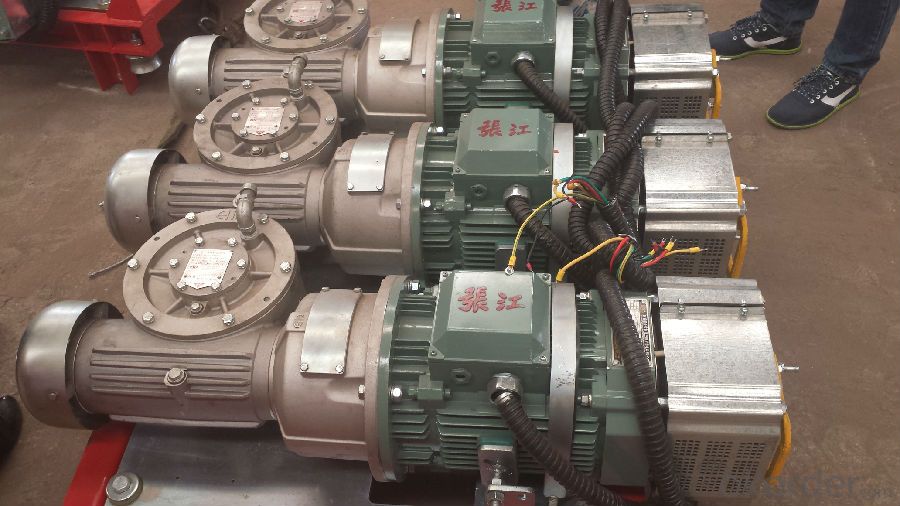

4. Both domestic and imported driving systems are available.

SC200/200 Building Lifter Specification

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage building hoist can be changed into single cage type,

| Type | Payload(kg) | Lifting Speed (m/min) | Motor Power(kw) | Safety Device | ||

| Twin Cage Hoist | No Counterweight | SC100/100 | 2*1000 | 0~60 | 2*3*11 | 2*SAJ30-1.4 |

| SC120/120 | 2*1200 | 0~60 | 2*3*11 | 2*SAJ30-1.4 | ||

| SC160/160 | 2*1600 | 0~60 | 2*3*15 | 2*SAJ30-1.4 | ||

| SC200/200 | 2*2000 | 0~60 | 2*3*15 | 2*SAJ40-1.4 | ||

| SC250/250 | 2*2500 | 0~60 | 2*3*18.5 | 2*SAJ50-1.4 | ||

| SC270/270 | 2*2700 | 0~60 | 2*3*18.5 | 2*SAJ50-1.4 | ||

| SC300/300 | 2*3000 | 0~60 | 2*3*22 | 2*SAJ50-1.4 | ||

| SC320/320 | 2*3200 | 0~60 | 2*3*22 | 2*SAJ50-1.4 | ||

| With Counterweight | SCD200/200 | 2*2000 | 0~60 | 2*2*15 | 2*SAJ40-1.4 | |

| SCD250/250 | 2*2500 | 0~60 | 2*2*18.5 | 2*SAJ50-1.4 | ||

| SCD270/270 | 2*2700 | 0~60 | 2*2*18.5 | 2*SAJ50-1.4 | ||

| SCD300/300 | 2*3000 | 0~60 | 2*3*15 | 2*SAJ50-1.4 | ||

| SCD320/320 | 2*3200 | 0~60 | 2*3*15 | 2*SAJ50-1.2 |

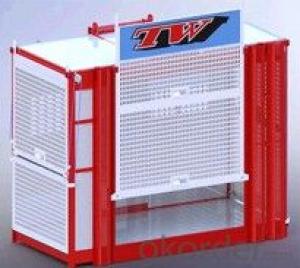

Images of SC200/200 Building Lifter

FAQ of SC200/200 Building Lifter

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks for a guide on how to change the tightness of the ropes on a construction hoist.

- <p>Adjusting the tension on a building hoist involves several steps. First, ensure the hoist is powered off and secured to prevent any movement. Locate the rope tensioning mechanism, often found at the base or top of the hoist. This could be a ratchet system, a spring-loaded mechanism, or a manual adjustment bolt. For ratchet systems, adjust the tension by turning the ratchet handle to tighten or loosen the rope. For spring-loaded mechanisms, adjust the spring tension by turning the adjustment bolt. Ensure the rope is properly seated in the pulley system and not frayed or damaged. After adjusting, test the hoist with a small load to ensure the tension is appropriate and the hoist operates smoothly. Always refer to the manufacturer's manual for specific instructions and safety precautions.</p>

- Q: This question asks whether a building hoist can be utilized in both indoor and outdoor environments for lifting objects.

- <p>Yes, a building hoist can be used both indoors and outdoors for lifting objects. These hoists are designed to handle heavy materials and are often used in construction settings. However, their use is subject to specific conditions and safety requirements. Outdoor use may require additional considerations such as weatherproofing and stability in various weather conditions, while indoor use must adhere to space limitations and structural integrity of the building. Always ensure that the hoist is suitable for the environment and that all safety protocols are followed to prevent accidents.</p>

- Q: Is it permissible to utilize personal lifting gear for the purpose of lifting objects?

- <p>Yes, you can use your own lifting equipment to lift objects, provided it meets safety standards and is suitable for the weight and type of objects being lifted. Always ensure that the equipment is in good working condition, and you are trained in its proper use to prevent accidents. Compliance with local regulations and guidelines is also crucial to avoid any legal repercussions.</p>

- Q: This question asks if single-rope lifts can experience malfunctions or create safety risks.

- <p>Yes, single-rope lifts can malfunction and pose safety hazards. Like any mechanical system, they are subject to wear and tear, component failure, and human error. Factors such as inadequate maintenance, poor weather conditions, and operator negligence can lead to malfunctions. Safety hazards may include rope breakage, sudden stops, or even derailment. However, modern lifts are equipped with multiple safety features such as emergency brakes and redundant systems to minimize these risks and ensure passenger safety. Regular inspections and adherence to safety protocols are crucial to prevent malfunctions and maintain the safety of single-rope lifts.</p>

- Q: This question asks for a comparison between lifting equipment used in indoor settings versus those used outdoors, focusing on their differences.

- <p>Indoor lifting equipment is designed for controlled environments, often smaller and more precise, with features like electric chain hoists or jib cranes. They are typically quieter, require less maintenance, and are suitable for tasks like assembly, manufacturing, and warehouse operations. Outdoor lifting equipment, such as gantry cranes or mobile cranes, is built to withstand harsh weather conditions, has higher load capacities, and is often used for construction, shipping, and heavy industry. These are more robust, may require more maintenance, and are designed for larger, heavier loads over uneven terrain.</p>

- Q: A building hoist is a mechanical device used in construction to lift materials and sometimes workers vertically. It is essential for the efficient movement of materials in high-rise construction.

- <p>The function of a building hoist is to facilitate the vertical transportation of materials, equipment, and sometimes workers within a construction site. It is particularly useful in high-rise buildings where manual lifting would be inefficient and unsafe. A building hoist allows for the rapid and safe movement of materials, reducing labor costs and improving construction speed.</p>

- Q: Explain how a lifting platform, specifically a building hoist, operates.

- <p>A building hoist, also known as a construction hoist, is a temporary lifting platform used in construction to lift materials and personnel vertically within a building under construction. It operates by using a motor-driven pulley system that runs on guide rails or tracks. The hoist is attached to the building structure and as the building grows, the hoist is extended upwards. The platform is loaded with materials or workers, and the operator controls the ascent or descent through an electrical switch or remote control. Safety features include limit switches to prevent over-travel, safety catches to stop the platform in case of a cable failure, and interlocks to ensure the platform cannot be operated when the doors are open.</p>

- Q: Is it possible to use personal lifting equipment for lifting extremely heavy objects?

- <p>Using your own lifting equipment to lift very heavy objects can be possible, but it depends on the weight capacity and safety standards of your equipment. Always ensure that your lifting gear is rated for the weight you intend to lift and that it is in good working condition. Additionally, it's crucial to follow all safety protocols, including proper setup, securing the load, and using personal protective equipment. For extremely heavy objects, professional lifting services are often recommended to ensure safety and prevent accidents.</p>

- Q: Explain the key differences between electric and hydraulic lifting equipment, including their power sources, efficiency, and applications.

- <p>Electric lifting equipment is powered by electric motors and typically operates through cables or batteries, making them quieter and more environmentally friendly. They are often used in indoor settings where noise and emissions are a concern. Hydraulic lifting equipment, on the other hand, uses hydraulic fluid and pistons to generate force, providing high power and torque. They are commonly used in heavy-duty applications and outdoors. Electric systems are generally more energy-efficient and have lower maintenance costs, while hydraulic systems offer greater power density and can handle heavier loads.</p>

- Q: Is it possible for a hydraulic cylinder in a building hoist to be serviced or replaced by individuals other than the manufacturer?

- <p>Yes, a hydraulic cylinder in a building hoist can be repaired or replaced by qualified individuals or companies other than the manufacturer. However, it is crucial to ensure that the service provider has the necessary expertise and follows the manufacturer's specifications to maintain safety and performance standards. Using non-genuine parts or improper installation can lead to safety hazards and void warranties. It is always recommended to consult with professionals who are familiar with the specific hoist model and have experience in hydraulic systems repair and maintenance.</p>

Send your message to us

Building Lifter SC200/200 Hot Galvanizing Processing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords