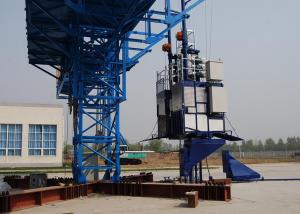

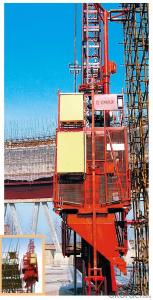

Multifunctional Building Hoist

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 30 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of CAMX Building Hoist SC200/200

The Multifunctional Hoist in such super high-rise buildings as the hyperbola cooling tower and the high chimney of the power plants, can carry workers, concrete and the long reinforcing bars. The hopper fixed by four pin rolls under the cage and the long reinforcing bars transportation system can be removed conveniently. In addition, we also manufacture multifunctional building hoist SC200 (single cage, with loading capacity of 2000kg), SC160/160(double cages, with loading capacity of 1600kg/1600kg), SC160 (single cage, with loading capacity of 1600kg).We also manufacture other styles according to the client's special requirements.

We has passed ISO9000 quality system authentication. We have powerful R&D centre and professional customer support team. Excellent quality and service are what we actually supply with.

Features of CAMX Building Hoist SC200/200

It is applied to carry workers, concrete and long reinforcing bars in construction of high-rise buildings, especially for power construction fields like high chimney, hyperbola cooling tower, bridge and dam. Since we launched multifunctional hoist, they have been adopted in construction of over 60 power plants in

Our multifunctional hoist has replaced traditional methods for construction of cooling tower and high chimney which together use goose-neck jib tower crane and windlass, and because it is installed inside of cooling tower for transporting of workers and materials, no another curve hoist is needed outside. So multifunctional hoists greatly reduce equipment demands and maintenance costs. Besides, our multifunctional hoist is praised for its friendly design that users can conveniently disassemble the transporting system of concrete and reinforcing bar, transferring it into a normal hoist.

Specifications of Multifunctional Hoist SC200/200

Lifting capacity | 2000kg/2000kg |

Lifting speed | 33 m/min, 38m/min, 0-60m/min (VVVF+PLC), 0-90m/min (VVVF+PLC) |

Max. lifting height | 400m |

Capacity of concrete hopper | 0.5m3/0.5m3 (1.5T/1.5T) |

Capacity of Rebar carrier | 600kg/600kg |

Max. length of the transported rebar | 9~12m |

Lifting speed of erection crane | 6m/min |

Motor type | Chinese motor or SEW motor |

Anti-drop safety device | With our patent |

Cage size (L x W x H) | 3.0x1.3x2.5m, 3.2x1.5x2.5m |

Mast section | 650x650x1508mm, 800x800x1508mm, hot dip galvanized or painted |

Anchor | distance 6-9m, hot dip galvanized or painted |

The whole machine can be designed according to your specific requirements | |

FAQ

Q:what is the capacity of concrete hopper?

A: Two hoppers equipped in SC200/200 for concrete transporting.

Each hopper with capacity of 0.7m3 ( 2T ), equal to 6~8 times of a cart

For example

H:100m, Speed 0~60m/min

Calculate with the load & unload time, 10 minutes for one transporting circle, 6 circles in one hour

So the concrete transporting capacity of SC200/200:

2×0.7×6= 8.4 m3/h

2×2×6= 24 T/h

Q: How about the capacity of reinforcing bar transporting

A: Multifunctional hoist can load reinforcing bars with the longest length of 9m, 600kg. Transporting system consists of bracket, clamp, and manual crane. They can be assembled and disassembled easily.

- Q: This question asks about the typical issues encountered with lifting devices and seeks advice on how to prevent these problems.

- <p>Common problems with lifting devices include mechanical failure, overloading, improper use, and lack of maintenance. To avoid these issues, ensure regular inspections and maintenance, follow the manufacturer's guidelines for weight limits, and train operators on proper use. Additionally, implement safety protocols, such as load testing and visual inspections before each use, and consider using lifting devices with safety features like overload protection and limit switches.</p>

- Q: Construction elevator positioning should consider which problems

- The construction elevator is short for construction. It is an important equipment in high-rise building construction, and construction site accident hazards easily, because it can cause many major accidents, injuries in the inspection should be listed as a key to check the content. Based on past accidents and on-site inspections, we often find topics that we think should be examined in a critical area

- Q: This question asks for a comparison between manual and automatic lifting systems used in construction equipment, highlighting their distinct features and operational differences.

- <p>Manual lifting systems in construction equipment rely on human effort to lift and move materials. They are often less expensive, require less maintenance, and are suitable for lighter loads or smaller-scale projects. However, they are labor-intensive, can be slower, and pose higher risks of injury due to the physical demands. Automatic lifting systems, on the other hand, use mechanical or electronic means to lift and move materials. They are more efficient, can handle heavier loads, and reduce the risk of injury by minimizing manual handling. These systems are often more expensive and require regular maintenance but offer precision, speed, and ease of operation, making them ideal for large-scale construction projects.</p>

- Q: The staff on the construction platform shall not exceed the number of people

- Different models have different load rating and platform lift platform size, this depends, suzhou new aluminium alloy elevator, Lin professional aluminum alloy lift platform.

- Q: Safe use of construction elevator

- 1, seek professional installation. 2, pay attention to safety when using, don't worry, because the elevator is not as fast as the elevator. 3, if there is a broken part, change it quickly, don't delay and feel free

- Q: Explain the differences between electric and electric-motor-driven building hoists in a few sentences.

- <p>Electric hoists are powered directly by electricity and use electric motors to lift and lower loads. They are typically smaller and more portable, suitable for lighter loads and indoor use. Electric-motor-driven hoists, on the other hand, use an electric motor to power a separate mechanism, often a winch or pulley system, to move loads. These are generally more robust, capable of handling heavier loads, and are often used in construction and industrial settings. The main differences lie in their power transmission methods, load capacity, and the environments in which they are used.</p>

- Q: Can a building hoist experience failure due to mechanical problems or the natural aging process?

- <p>Yes, a building hoist can malfunction due to mechanical issues or wear and tear. Mechanical problems can arise from various factors such as poor maintenance, overloading, or manufacturing defects. Wear and tear, which is the gradual deterioration of a machine's parts over time, can also lead to malfunctions. Regular inspections and maintenance are crucial to identify and rectify these issues, ensuring the safety and efficiency of the hoist operation.</p>

- Q: This question asks for a comparison between electric and electric-hydraulic building hoists, highlighting their distinct features and how they differ from each other.

- <p>Electric building hoists are powered solely by electric motors, which provide direct and precise control over the lifting and lowering of loads. They are quieter, require less maintenance, and are more energy-efficient compared to their hydraulic counterparts. On the other hand, electric-hydraulic building hoists combine the power of an electric motor with the force amplification capabilities of hydraulic systems. These hoists offer greater lifting capacity and can handle heavier loads but are generally more complex, requiring regular maintenance of hydraulic components. They are also louder and may consume more energy. The choice between the two often depends on the specific requirements of the lifting task, such as load capacity, precision, and environmental considerations.</p>

- Q: Is it possible to utilize a single-rope lifting system in the context of a building hoist?

- <p>Yes, a single-rope lifting system can be used in a building hoist. This system is common in construction elevators, where a single rope is used to lift and lower the hoist's cage. The rope is attached to a motor at the top and passes over sheaves or pulleys to provide mechanical advantage. It is essential to ensure that the rope is strong enough to support the load and that the system is equipped with safety features such as overload protection and emergency braking mechanisms to prevent accidents.</p>

- Q: Is it possible to substitute a hydraulic cylinder for an electric motor in a building hoist system?

- <p>A hydraulic cylinder can indeed be used as a replacement for a motor in a building hoist, but it requires a different system design. Hydraulic systems use fluid pressure to generate linear motion, which can be harnessed to lift and lower loads. They offer high power-to-weight ratios and can handle heavy loads, making them suitable for hoisting applications. However, they require a power source for the hydraulic pump, and the system must be designed to manage fluid flow, pressure, and safety features. Unlike electric motors, hydraulic systems also need regular maintenance and can be less energy-efficient. Despite these differences, with proper design and engineering, a hydraulic cylinder can effectively replace an electric motor in a hoist system.</p>

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 1990 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Southeast Asia;South America |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | SHANGHAI |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 300 |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 15 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Multifunctional Building Hoist

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 30 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords