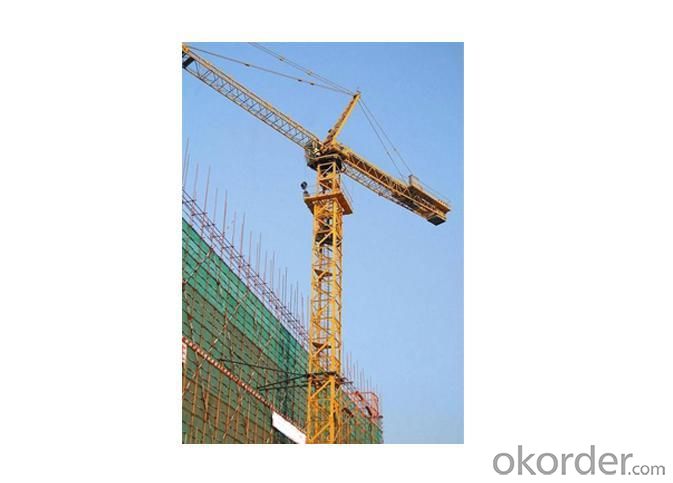

QTZ40B Tower Crane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 1000 Sets per Year set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of QTZ40B Tower Crane

1.QTZ40B Tower Crane

2.Rated lifting moment:400KN.m

3.Max. lifting load:4t

4.Span:48m

5.Rated lifting load:0.8t

QTZ40B tower crane

CE, GOST (For Russia) and ISO certified tower cranes QTZ25, QTZ30, QTZ40B, QTZ50, QTZ50B, QTZ63, QTZ80, QTZ100, QTZ125, QTZ160, QTZ250 and different kind of construction hoists.

The Tower crane QTZ250 can lift 12 tons, max range 70M, max height 220M.

Table for the Main technical date

The structure name | ITEM | Specification |

Hoisting structure | Motor | YZD200L1-4/8/32 15/15/4Kw |

Decelerator | ZQ50-12.64 | |

Detent | YWZ-300-45 | |

Wire-rope | 6×19-12.5-1770-I-I | |

Slewing mechanism | Motor | YD132M-4/8 3/4.5Kw |

Decelerator | XX4-80.195 | |

Fluid coupling | YOX-250A | |

Slewing fulcrum | HSW.30.1220 | |

Jib lubbing mechanism | Motor | Y100L2-4/6 2.2/1.5kW |

Decelerator | WXJ100-31 | |

Wire-rope | 6×19-6.2-1770-I | |

Hoisting mechanism | Motor | YD132M-4 3kW |

Cylinder stroke | 1320mm | |

Cylinder diameter | 1775mm | |

Rated working pressure for the cylinder | 20MPa |

Table for the main structure

Name | Structure Drawing | The main material | Note |

Standard Segment | Mail staff angle steel: ∠140×140×12 | Section size :1494×1494 height:2200 | |

Jib Boom | First quarter staff: tube76×8 | The Jib boom is formed by eight parts | |

- Q: Is it possible to utilize a building hoist for lifting materials during demolition projects?

- <p>While a building hoist is typically designed for construction purposes to lift materials and personnel, it is not advisable to use it for demolition work. Demolition involves hazardous conditions with falling debris and unstable structures, which can compromise the safety and integrity of the hoist. Instead, specialized equipment like wrecking balls, hydraulic shears, and cranes are more suitable for demolition tasks. These are engineered to handle the heavy loads and unpredictable conditions associated with breaking down structures safely.</p>

- Q: This question asks for a comparison between electric and pneumatic building hoists, highlighting their distinct features and operational differences.

- <p>Electric building hoists are powered by electricity and are known for their high lifting capacity, speed, and efficiency. They are suitable for heavy-duty applications and can be automated for continuous operation. Pneumatic hoists, on the other hand, use compressed air to generate lifting force. They are quieter, require less maintenance, and are safer in environments where electrical sparks could be hazardous. However, they have lower lifting capacities and are generally slower compared to electric hoists. Pneumatic hoists are also more suitable for applications requiring precise control over the load.</p>

- Q: What are the primary parts that make up a building hoist system?

- <p>The main components of a building hoist include the hoist machine, which is the driving mechanism; the hoist shaft, a vertical structure that houses the hoist; the lifting platform or cage, which carries materials and personnel; the mast or tower, providing support and stability; the counterweight, which balances the load; safety devices such as limit switches and brakes; the control system for operation; and the electrical system that powers the hoist. Additionally, there are guide rails, cables, and buffers that ensure smooth and safe operation.</p>

- Q: This question asks for guidance on the upkeep and repair procedures for a building hoist, a mechanical device used for lifting materials in construction.

- <p>To maintain and repair a building hoist, follow these steps: Ensure regular inspections by qualified personnel, checking for wear and tear, and addressing any issues promptly. Lubricate moving parts as per the manufacturer's guidelines to reduce friction and prolong component life. Replace worn-out cables, pulleys, and other critical components to prevent accidents. Keep the hoist clean and free from debris to prevent jams and malfunctions. For repairs, always consult the manufacturer's manual or hire professional technicians to avoid safety hazards. Regular maintenance and prompt repair are crucial for the safe operation of building hoists.</p>

- Q: Why is the construction elevator not up to the roof

- The free end of the construction of the lift height is only 7.5 meters high, general construction elevator drive now is the case, so the hoisting cage height and drive around 4.5 meters high, the other national standard construction elevator ceiling limit moves, drive above about 1.8 meters away from the top of the rails. So it's the free end of the construction elevator that can't satisfy the roof.

- Q: This question asks if a building hoist can be set up either inside or outside a building.

- <p>Yes, a building hoist can be installed both indoors and outdoors. The choice between indoor and outdoor installation depends on the specific requirements of the construction project, the available space, and the building's design. Outdoor hoists are often used for high-rise construction, while indoor hoists are more common in multi-story buildings or where external space is limited. Both types require careful planning and adherence to safety regulations to ensure the safe and efficient movement of materials and personnel.</p>

- Q: This question asks for methods to prevent leakage in hydraulic cylinders used in building hoists.

- <p>To prevent hydraulic cylinder leaks in a building hoist, follow these steps: Regularly inspect and maintain the hydraulic system to ensure all seals and gaskets are in good condition. Replace any worn or damaged components promptly. Ensure the hydraulic oil is clean and at the correct level to avoid air bubbles or cavitation which can cause leaks. Check the cylinder rods for scratches or damage and polish or replace them if necessary. Maintain the correct operating pressure and avoid overloading the hoist. Regularly lubricate moving parts to reduce friction and wear. Implement a routine maintenance schedule to catch and address potential issues before they lead to leaks.</p>

- Q: This question asks whether a building hoist can be utilized for lifting various kinds of objects.

- <p>Yes, a building hoist can be used for lifting multiple types of objects. It is designed to handle a variety of materials, including construction materials, tools, and equipment. The hoist's capacity and design may vary, allowing it to accommodate different weights and sizes. However, it is crucial to ensure that the hoist's lifting capacity is not exceeded and that the objects are secured properly to prevent accidents. Always refer to the manufacturer's guidelines for specific weight limits and safety procedures.</p>

- Q: Is it possible to store lifting equipment in a residential setting such as a home or garage?

- <p>Yes, you can store your lifting equipment in your home or garage, but there are several considerations to keep in mind. Ensure that the space is dry, well-ventilated, and free from extreme temperatures to prevent rust or damage. Store equipment on stable, level surfaces to prevent tipping. Keep equipment away from children and pets for safety. Regularly inspect equipment for wear and tear, and store it properly when not in use to maintain its condition. Always follow the manufacturer's guidelines for storage to ensure the longevity and safety of your equipment.</p>

- Q: Is it possible for a building hoist to experience malfunctions that lead to damage?

- <p>Yes, a building hoist can malfunction and cause damage. Malfunctions can occur due to various reasons such as mechanical failure, operator error, or poor maintenance. These malfunctions can lead to accidents, including dropped loads, structural damage, or even injuries to workers. Regular inspections, proper maintenance, and adherence to safety protocols are crucial to minimize the risk of hoist malfunctions in construction settings.</p>

1. Manufacturer Overview

| Location | Beijing,China |

| Year Established | 2003 |

| Annual Output Value | |

| Main Markets | 15.00% Eastern Europe 15.00% South America 10.00% Mid East 10.00% Western Europe 10.00% North America 5.00% Oceania 5.00% Eastern Asia 5.00% Central America 5.00% Southeast Asia 5.00% Northern Europe 5.00% Southern Europe 5.00% South Asia 5.00% Africa |

| Company Certifications | ISO9001:2000;CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | 11-20 People |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

QTZ40B Tower Crane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 1000 Sets per Year set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords