Building Hoist wih Hot galvanized Mast BBM 2 Normal

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description for BBM2 passenger hoist

The products of Broadbond can reach the level of a world’s leading by introducing the world-class product design concepts such as row material selecting, structure designing, working mechanism, controlling system, efficiency, safety and reliability.

Features for BBM2 passenger hoist

In order to improve the quality of hoists, We has a strict raw material purchasing control system to ensure the security and reliability of the product. Also all equipments such as steel, electrical components, cables, high-strength bolts and spare parts are used by all famous international brands and domestic enterprise products. Moreover, in the process of producing hoist the application of precision CNC Cutting production lines guarantees Product components and accurate processing of size.

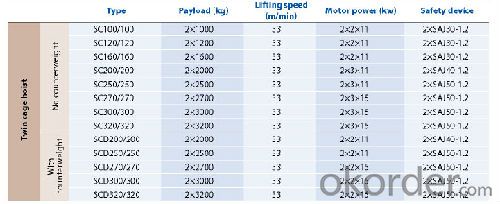

Specification for BBM2 passenger hoist

Pictures for for BBM2 passenger hoist

FAQ for BBM2 passenger hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

- Q: The user is inquiring about the possibility of purchasing a second-hand construction hoist.

- <p>Yes, you can buy a used building hoist. Many companies specialize in selling refurbished or used construction equipment, including building hoists. You can find them through online marketplaces, auction sites, or by contacting construction equipment dealers directly. It's important to inspect the hoist for any damages or wear and ensure it meets safety standards before purchase. Additionally, consider the hoist's age, maintenance history, and any warranties that might still be valid.</p>

- Q: This question asks if a building hoist can be utilized for the purpose of lifting heavy objects.

- <p>Yes, a building hoist is specifically designed for lifting heavy objects in construction settings. It is a mechanical device that can lift and lower materials such as concrete, bricks, and tools to various levels of a building under construction. Building hoists are engineered to handle substantial weight and are equipped with safety features to ensure secure and efficient operation. However, it is crucial to adhere to the hoist's weight capacity and safety guidelines to prevent accidents and ensure the proper use of the equipment.</p>

- Q: How many kw is the sc construction elevator

- A double cage, the three-drive is 11 * 3 * 2KW and the two drives are 12 * 2 * 2KW

- Q: This question asks for the method to determine the maximum weight that a building hoist can safely lift.

- <p>To calculate the weight limit of a building hoist, you must consider several factors: the hoist's mechanical capacity, the strength of the supporting structure, the load-bearing capacity of the cables or chains, and the safety regulations in place. Start by checking the manufacturer's specifications for the hoist's maximum load capacity. Then, ensure the hoist's supporting structure can withstand the weight and the force exerted during lifting. Inspect the cables or chains for any signs of wear and ensure they meet the required strength standards. Finally, adhere to local safety regulations, which often mandate a safety factor below the hoist's rated capacity to prevent overloading. Always consult with a professional engineer or the hoist manufacturer for precise calculations and safety guidelines.</p>

- Q: Is it permissible to use a building hoist for the purpose of lifting hazardous materials?

- <p>A building hoist is typically not designed for lifting dangerous materials. It is meant for the transportation of construction materials and personnel within a building. Lifting hazardous materials requires specialized equipment and procedures to ensure safety. Always refer to the manufacturer's guidelines and local regulations for the appropriate use of hoisting equipment and handling of dangerous materials.</p>

- Q: What is the height of protecting door protection of construction elevator

- Currently tunnel door is no national standard, the only industry standards and enterprise standards, is important when choosing the tunnel door manufacturers see manufacturers have tunnel door production qualification and testing report. Formal manufacturer all have these qualifications, such as lei Chen group, tunnel protection door, explosion-proof door the qualification is very complete, you can be important consideration.

- Q: This question asks for the method to change the angle at which a building hoist operates.

- <p>Adjusting the angle of a building hoist involves several steps. First, ensure the hoist is turned off and disconnected from power sources. Next, locate the hoist's tilt adjustment mechanism, which is typically found at the base or on the mast. This mechanism often consists of a set of bolts or pins that can be loosened to allow the angle to be changed. Adjust the angle by moving the mast or base to the desired position, ensuring it is level and stable. Once the correct angle is achieved, tighten the bolts or pins to secure the hoist in place. Always follow the manufacturer's guidelines and safety precautions when making adjustments to prevent accidents.</p>

- Q: This question asks for a comparison between electric and electric-hydraulic building hoists, highlighting their distinct features and how they differ from each other.

- <p>Electric building hoists are powered solely by electric motors, which provide direct and precise control over the lifting and lowering of loads. They are quieter, require less maintenance, and are more energy-efficient compared to their hydraulic counterparts. On the other hand, electric-hydraulic building hoists combine the power of an electric motor with the force amplification capabilities of hydraulic systems. These hoists offer greater lifting capacity and can handle heavier loads but are generally more complex, requiring regular maintenance of hydraulic components. They are also louder and may consume more energy. The choice between the two often depends on the specific requirements of the lifting task, such as load capacity, precision, and environmental considerations.</p>

- Q: This question asks whether a building hoist can be utilized to lift various objects with differing weights and dimensions.

- <p>Yes, building hoists are designed to lift a variety of objects with different weights and sizes. They are versatile and adjustable, allowing for the transportation of materials such as bricks, concrete, and equipment. However, each hoist has a specific weight capacity that must not be exceeded. It's crucial to ensure that the objects being lifted are within the hoist's capacity and that the hoist is properly configured for the size and shape of the objects to ensure safety and efficiency.</p>

- Q: Should a fire extinguisher be equipped in the construction elevator?

- The dual-purpose construction elevator should be needed

Send your message to us

Building Hoist wih Hot galvanized Mast BBM 2 Normal

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords