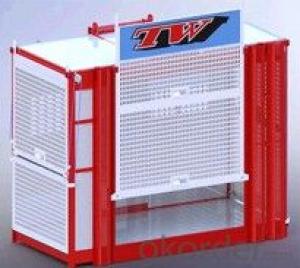

SC200/200 Construction elevator

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Hoist SC200/200

Condition: New

Application: Construction

Payload(kg):2*2000

Lifting Speed(m/min):0~45

Motor Power(kw): 2*3*22

Safety Device: 2*SAJ50-1.4

Cage: Single/double cages

Counterweight: No

Certification: CE/ ISO

Place of Origin: China(Mainland)

Model Number: Type:SC200/SC200

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package Delivery Detail: 10-15days

Main Parts of Building Hoist

Feature:

● Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist

● The VF system has current-restriction function, ensuring a small current when motor start up

● The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake

and prolongs the spare parts'life.

● The system applies the special software for hoists developed by our company, making the operation more safe and

reliable.

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks whether a building hoist can develop operational issues due to incorrect usage or lack of maintenance.

- <p>Yes, a building hoist can malfunction due to improper use or inadequate maintenance. Improper use may include overloading the hoist, using it in unsuitable conditions, or operating it without proper training. Inadequate maintenance can lead to wear and tear, lubrication issues, and component failures. Regular inspections, proper usage guidelines, and timely repairs are crucial to prevent malfunctions and ensure the safety of the hoist and its operators.</p>

- Q: Does the misuse or incorrect use of lifting equipment pose a risk of injury to workers?

- <p>Yes, improper or incorrect use of lifting equipment can cause serious injury to workers. This can include accidents such as dropping loads, which can lead to crushing injuries or being struck by falling objects. Additionally, improper lifting techniques can lead to musculoskeletal injuries, such as back strains or sprains. It's crucial for workers to be trained in the safe operation of lifting equipment and to follow all safety protocols to minimize the risk of injury.</p>

- Q: This question asks whether building hoists can be utilized in limited areas like rooms or tunnels.

- <p>Yes, building hoists can be used in confined spaces such as rooms or tunnels, but it depends on the specific design and size of the hoist. Compact and portable hoists are available for use in tight spaces. However, safety considerations, space dimensions, and the weight capacity of the hoist must be taken into account. It's crucial to ensure that the hoist is suitable for the confined area and that all safety protocols are followed to prevent accidents.</p>

- Q: This question asks whether a hydraulic building hoist can be used in both indoor and outdoor environments and seeks reasons for its versatility.

- <p>A hydraulic building hoist can be used both indoors and outdoors. These hoists are designed to be versatile and durable, capable of withstanding various weather conditions when used outdoors. They are also compact and can be easily maneuvered in indoor spaces. The primary reason for their versatility is the robust construction and the ability to handle different loads with precision. Additionally, hydraulic systems are less affected by electrical interference, making them suitable for environments with fluctuating power supplies. However, it's important to ensure that the hoist is properly maintained and protected from extreme weather conditions to prolong its lifespan and ensure safety.</p>

- Q: Explain how a lifting platform, specifically a building hoist, operates.

- <p>A building hoist, also known as a construction hoist, is a temporary lifting platform used in construction to lift materials and personnel vertically within a building under construction. It operates by using a motor-driven pulley system that runs on guide rails or tracks. The hoist is attached to the building structure and as the building grows, the hoist is extended upwards. The platform is loaded with materials or workers, and the operator controls the ascent or descent through an electrical switch or remote control. Safety features include limit switches to prevent over-travel, safety catches to stop the platform in case of a cable failure, and interlocks to ensure the platform cannot be operated when the doors are open.</p>

- Q: This question asks for the safety precautions that should be taken when operating electric-hydraulic construction hoists.

- <p>Safety measures for using electric-hydraulic building hoists include regular maintenance and inspection to ensure all components are in good working order. Operators must be trained and certified, following all safety protocols. Never exceed the hoist's load capacity. Ensure that safety hooks and chains are in place and secure. Keep the hoist area clear of debris and unauthorized personnel. Use proper lifting techniques and avoid sudden starts or stops. Always inspect the load before lifting to ensure it is stable and secure. Emergency stop switches should be easily accessible. Ensure that all safety guards are in place and functioning properly. Adhere to all local regulations and manufacturer's guidelines.</p>

- Q: Is it possible for a single lifting device to simultaneously lift multiple objects with varying weights?

- <p>Yes, a single lifting device can be used to lift multiple objects at once with different weights, provided the total weight does not exceed the device's lifting capacity. The device must be designed to handle the combined weight and ensure even distribution of the load. Safety measures and proper securing of the objects are crucial to prevent accidents. It's important to follow the manufacturer's guidelines and never exceed the maximum load capacity to avoid damage or injury.</p>

- Q: What are the key safety rules and regulations that must be followed when operating a building hoist?

- <p>Safety regulations for using a building hoist include ensuring that the hoist is inspected and certified by a qualified person before use. Operators must be trained and certified. The hoist should be used only for its intended purpose, and load limits must never be exceeded. Regular maintenance and checks are required to ensure the hoist remains in good working order. Safety devices such as limit switches and emergency stops must be operational. The hoist area should be kept clear of obstructions, and warning signs should be posted. Personal protective equipment (PPE) must be worn by operators and anyone in the vicinity. Overhead protection should be provided to prevent objects from falling onto the hoist. Compliance with local and national regulations is also crucial.</p>

- Q: This question asks about the various mechanisms that enable lifting in building hoists, which are essential for construction projects.

- <p>Building hoists utilize several types of lifting mechanisms to efficiently move materials and personnel. The most common types include: 1. Geared Hoists, which use a system of gears to lift and lower loads. 2. Electric Chain Hoists, powered by electric motors and are suitable for heavier loads. 3. Air Hoists, which use compressed air to generate lifting force and are ideal for environments where electricity is a hazard. 4. Manual Chain Hoists, operated by hand and best for lighter loads. 5. Electric Wire Rope Hoists, which offer high lifting capacities and are controlled by electric motors. 6. Pneumatic Hoists, similar to air hoists but use pneumatic power for lifting. Each type has specific applications and safety considerations, making them suitable for different construction needs.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of employing lifting equipment in the construction industry.

- <p>Advantages of using lifting equipment in construction include increased efficiency, reduced manual labor, and the ability to handle heavy loads safely. It can also improve safety by reducing the risk of injury from lifting heavy objects manually. Additionally, it allows for faster construction times and can access hard-to-reach areas. Disadvantages include high initial costs for purchasing or renting the equipment, potential for mechanical failure, and the need for skilled operators. There is also a risk of accidents if the equipment is not used properly, and it may require more maintenance and training for staff.</p>

Send your message to us

SC200/200 Construction elevator

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords