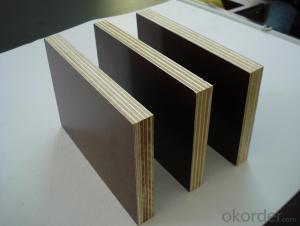

Home Depot 1/4 Plywood - Brown Film Faced Plywood Shuttering Plywood Phenolic Glue Construction Plywood 18mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Item name:Black/Brown Film Faced Plywood

Size:1220*2440/1250*2500

Core: poplar/hardwood/combi/birch

Glue: WBP, melamine, phenolic

Description:

Film Faced Plywood | ||

Size | 1220*2440mm,1250*2500mm,915*1830mm,1500*3000mm Or as clients’ requests | |

Film | Black(domestic) film, Dynea(import)brown film ,brown(domestic)film, black(domestic) film,red film, yellow film; | |

Thickness | 9mm,12mm,15mm,18mm,21mm etc; | |

Core | Poplar, Hardwood, Birch , Combi,Eucalyptus, etc; | |

Tolerance | Length/width :+/-0.2mm; Thickness: +/-0.5mm | |

Glue | MR(water proof), MELAMINE(water proof), WBP(phenolic); | |

Mositure content | 8%-12% | |

Modulus of rupture | >30MPa | |

Modulus of Elasticity | >6000MPa | |

packing | bottom is pallets, covered with plastic film,around is carton or plywood, strenghthen by steel or iron 3*6 | |

quantity | 20GP | 8pallets/22M3 |

40GP | 16pallets/42M3 | |

40HQ | 18pallets/55M3 | |

Usage | making construction formwork plywood, concrete formwork plywood,marine plywood etc | |

Payment | TT or L/C at sight | |

Delivery Time | Within 20 days receiving deposit or original L/C at sight | |

Features:

1. The face should be of high resistance to corrosion and moisture.

2. The face should be smooth and easy to take off from cement and easy to clean.

3. The core should be water resistant and won’t swell.

4. The core should be strong enough and won’t break.

5. The edge should be sealed and water proof.

Advantages of our film faced plywood

1. Above 18mm thickness film faced plywood , could be used 20 time at least

2. The inside each veneer is whole core

3. Each veneer is glued totally

4. Boiled for 10 hours , will not cracking

5. Twice hot press to strong joining capacity

6. Cold press again to strong joining capacity

7. 100% Dry

8. We have another glue making factory

FAQ

A. Quality :

With the skilled worker ,mature technology and ten years experience ,all our plywood are steady quality .

B. Price:

Due to the skilled worker ,mature technology and an experienced operating system , we can

quote you competitive price , so that you will have the price advantage to capture your market.

C.Service:

7*24hours , if any need, you can email or call us,we will do our best to meet your demand

D.Export experience:

Over ten years experience for exporting ,We are much familiar with

the export operation .

- Q: The structure of the plywood at the same time meet two basic principles

- the fiber direction and the table are parallel to the long core plate or the middle plate. When forming a slab, the panel and the backplate must face outward.

- Q: Selection of plywood in plywood production

- It is noteworthy that the common decorative panels are divided into natural wood veneer panels and artificial veneer panels

- Q: Plywood is generally used in applications where the strength and stability of the material are relatively high

- For example: Yunshan plywood is a soft Murray plywood, it can be used for housing flooring, walls and ceiling, coated surface can also be sprayed after the coating.

- Q: Contemporary plywood market development

- as well as foreign high-quality hardwood wood constantly added for the Chinese plywood industry's continuous development To provide a wealth of raw materials; adequate human resources,

- Q: Wood board, plywood, MDF What is the difference

- Blockboard thickness specifications for the 16,19,22,25 mm quality grade is divided into one, two, three three levels

- Q: What harm does the plywood factory work?

- Occupational acute benzene poisoning is the workers in the professional activities, short-term inhalation of high-dose benzene vapor caused by the central nervous system suppression as the main manifestation of systemic diseases

- Q: What is the difference between plywood glue E0E1?

- Urea-formaldehyde glue: moisture-proof glue / for interior decoration, furniture, can not be used for outdoor.

- Q: What are the defects of the plywood?

- partially intergrown knOts surrounded by the surrounding wood part of the length of its cross-section around the length of more than 1/4 to 3/4, texture Kuang hard.

- Q: What kind of glue is today's plywood?

- if you want to make general indoor wood products, you can use E1 (or even E0) urea formaldehyde;

- Q: Plywood in the processing of defects

- sand through sandlng through due to excessive sanding the table, local wear exposed layer or the next layer of veneer

Send your message to us

Home Depot 1/4 Plywood - Brown Film Faced Plywood Shuttering Plywood Phenolic Glue Construction Plywood 18mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords