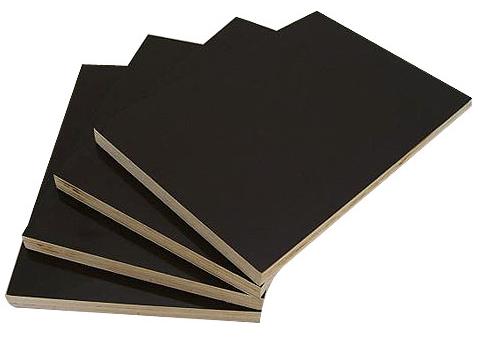

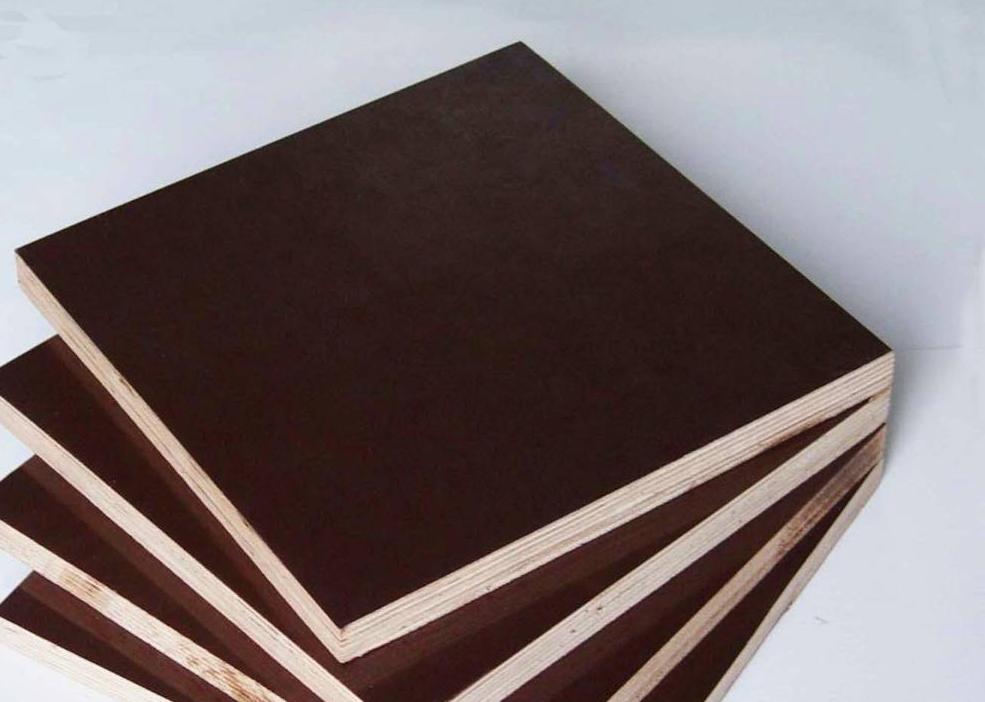

Home Depot 4x8 Marine Plywood / Film Faced Plywood / Shuttering Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

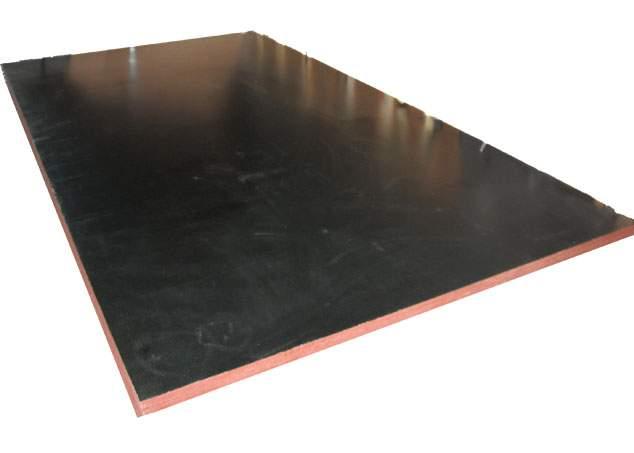

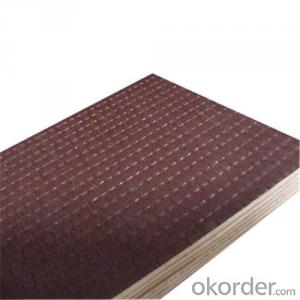

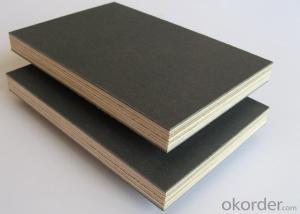

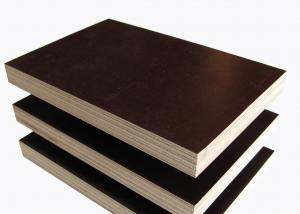

Item:film faced plywood

Size:1220x2440mm

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,customer's thickness is available

Color:Brown,Black,Red

Description:

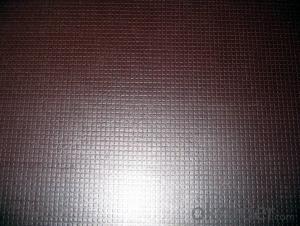

Face/Back | Black film/brown film |

Color | Black,brown |

Core: | Poplar,hardwood,combi |

Grade: | Construction grade |

Glue: | MR/Melamine/WBP |

Size(mm) | 1220x2440mm,1250x2500mm |

Thickness | 9mm/12/mm/15mm/17mm/18mm/19mm/21mm/23mm/25mm |

Moisture | 8-16% |

Packing | Inter packing:0.2mm plastic; Ourter packing:bottom is pallets, covered with plastic film,around is carton or plywood, strenghthen by steel or iron 3*6 |

Usage | used for construction |

Minimum Order | 55CBM,1x40HQ |

Payment | T/T or L/C at sight |

Delivery Time | Within 20 days receiving deposit or original L/C at sight |

Features:

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use film faced plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time

Storage:

always clean and repair the formwork panels before storage, the formwork should then be stacked off the ground on level supports and under cover. framed formwork panels should be stacked alternately face and back to back to avoid face damage by bolts etc. if panels are wet, do not allow them to dry too rapidly.

FAQ:

1.Can I be your agent?

Yes, welcome to deep cooperation. We have big promotion in the market now. For the details please contact with our overseas manager.

2.Is OEM available?

Yes, OEM is available. We have professional designer to help your brand promotion.

3.Is the sample available?

Yes, samples are available for you to test the quality.

4.Are the products tested before shipping?

Yes, all was qualified before shipping. We test every batch every day.

5.What's your quality guarantee?

We have 100% quality guarantee to customers. We will be responsible for any quality problem.

6.What's benefit will you bring?

Your client satisfied on the quality.

Your client continued orders.

Your can get good reputation from your market and obtain more orders.

- Q: The structure of the plywood at the same time meet two basic principles

- So the plywood is usually three, five, seven odd level layer. The name of each layer of the plywood is: the surface of the board is called the table, the inner plate is called the core board;

- Q: Judging wood is the standard for plywood

- If you can identify the type of wood used by your own furniture, it will help you identify the true value of the furniture

- Q: What plywood is now commonly used?

- Urea-formaldehyde glue: moisture-proof glue / for interior decoration, furniture, can not be used for outdoor.

- Q: Multilayer board and plywood difference

- multi-layer board is one of the commonly used materials processing enterprises, is a wood-based panel

- Q: Distinguish between multilayer boards and plywood

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: What are the defects of the plywood?

- dead dead knots formed by the dead branches of trees, knots surrounded by the surrounding wood together, or even only part of the length of its cross-section of the length of about 1/4 or less than 1/4 , Texture hard or soft, and sometimes fall off the formation of empty.

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- It is usually made of odd-numbered veneers and The fibers of the adjacent veneers are perpendicularly bonded to each other

- Q: What kind of glue is today's plywood?

- if you want the wood products have a stronger waterproof and moisture-proof performance, you can use E1 (or even E0) melamine glue.

- Q: What are the plywood specifications?

- International Organization for Standardization of ordinary plywood production, from the structure, finished product moisture content, quality 3 to make the provisions:

- Q: What are the types of veneer veneer veneer?

- Common is a single-sided veneer veneer plywood. Decorative veneer commonly used species of birch, ash, oak, water green Kong, elm, maple wood, walnut, etc.

Send your message to us

Home Depot 4x8 Marine Plywood / Film Faced Plywood / Shuttering Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords