Fireproof glass partition(Borosilicate Float glass 4.0)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

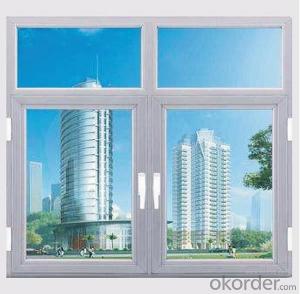

Borosilicate glass is a kind of high content of borosilicate. Borosilicate 4.0 fireproof glass is named by its expansion coefficient of 4.0 ± 0.1 × 10-6/K. Glass is required to have excellent stability when used as a fireproof glass partition.The fire resistance stability of this glass is currently the best among all fireproof glass, and the stable fire resistance duration can reach 120 min (E120).

Moreover, borosilicate glass also has high transmittance at high temperatures.This function is critical in case of fire and poor visibility. It can save lives when evacuating from buildings. High light transmittance and excellent color reproduction mean that it can still look beautiful and fashionable while ensuring safety.

Advantage

• Fire protection duration exceeding 2 hours

• Excellent ability at thermal shack

• Higher softening point

• Without self-explosion

• Perfect in visual effect

Application scene

In high-end dense office buildings, using borosilicate float glass 4.0 as a fire barrier can help people gain more escape time and prevent the spread of fire due to its effective fire prevention duration of up to 2 hours in the event of a fire.

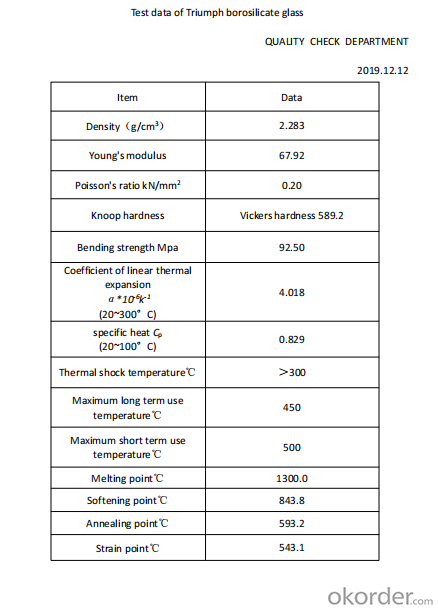

Actual measured parameters of triumph borosilicate glass (for reference)

Thickness Processing

The thickness of the glass ranges from 4.0mm to 12mm, and the maximum size can reach 4800mm×2440mm(The biggest size in the world).

The biggest size in the world:4800mm×2440mm

Processing

Pre-cut formats, edge processing, tempering,drilling, coating, etc

Package and transport

Minimum order quantity: 2 tons, capacity: 50 tons/day, packing method: wooden case.

Company introduction

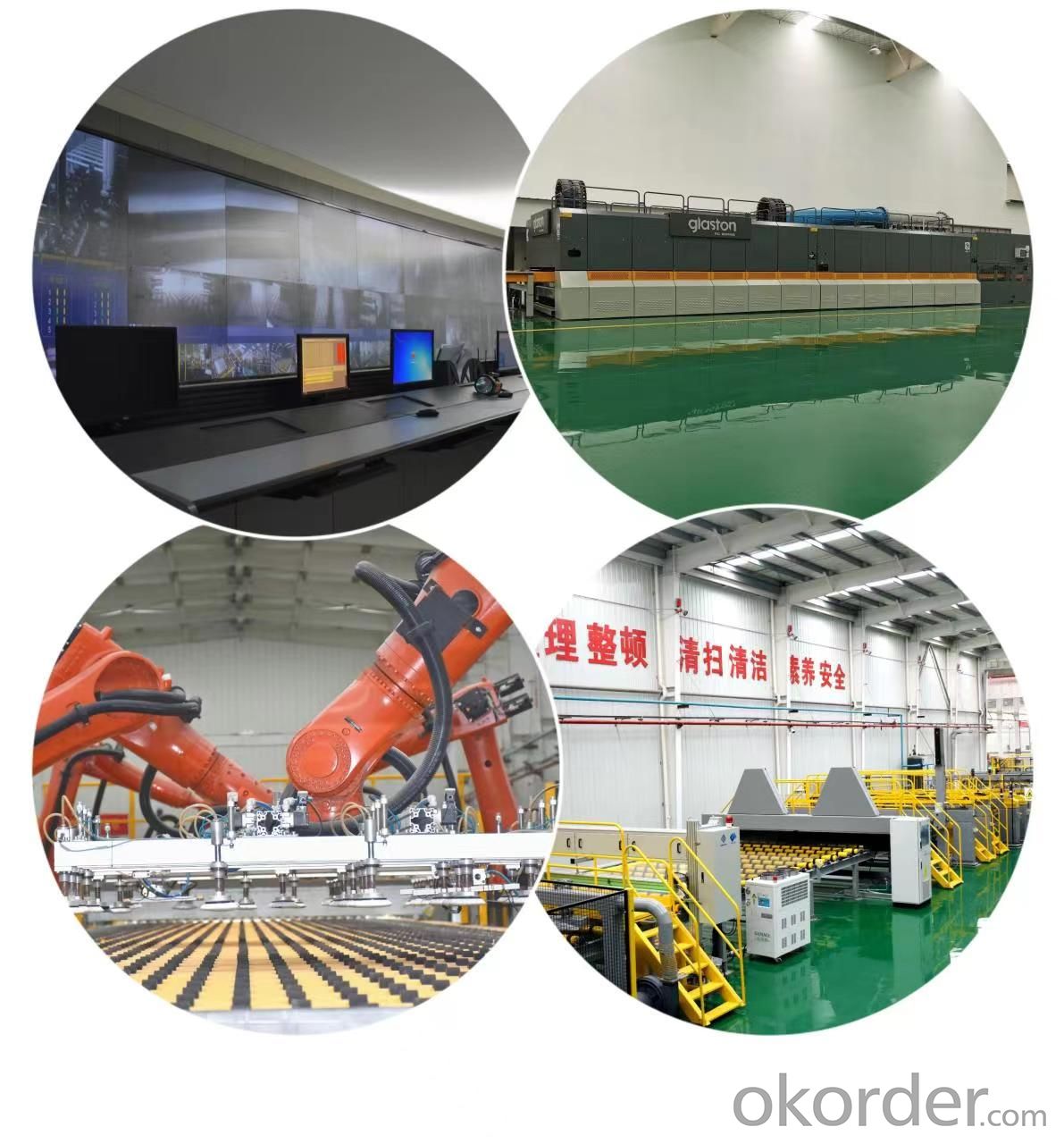

Founded in 1922,China Yaohua Glass Group Co.,Ltd.(hereinafter referred to as "Yaohua Group") is a second-tier subsidiary of Triumph Science&Technology Co.,Ltd..It is the first manufacturer in Asia to continuously produce flat glass by machine,and is known as “the cradle of Chinese glass industy”.

Yaohua Group, as the core platform of Triumph Science & Technology Group for high-quality float and special glass, now has 14 independent legal entity enterprises, with assets of over 10 billion yuan, annual revenue of more than 5 billion yuan and total annual profit of more than 1 billion yuan. The group covers 10 prefecture-level cities in six provinces including Heilongjiang,Hebei, Shandong.,Henan, Anhui and Sichuan, with 4000 employees.

It has three glass plates.They are float glass ,special glass and deep-processing glass. The special glass unti is composed of ENGYANG TRIUMPH SILICON MATERIALS CO., LTD. 、 Qinhuangdao Scinan Specialty Glass Co.,Ltd.、Triumph Bnegbu Glass Co.,Ltd. and CNBM(PUYANG) PHOTOELECTRIC MATERIALS CO., LTD.

Fengyang Triumph Silicon Materials Co., Ltd. Is the subsidiary of China National Building Material Group Co., Ltd., a Fortune 500 company. Fengyang Triumph production line adopts oxygen combustion + electric boosting technology + platinum system technology with completely independent intellectual property rights.The company mainly produces borosilicate float glass 3.3 and borosilicate float glass 4.0.

The company plans to build a fully electric fused borosilicate float galss 3.3 production line with a melting capacity of 30t/d. It is expected that the ignition conditions will be available in 2023.

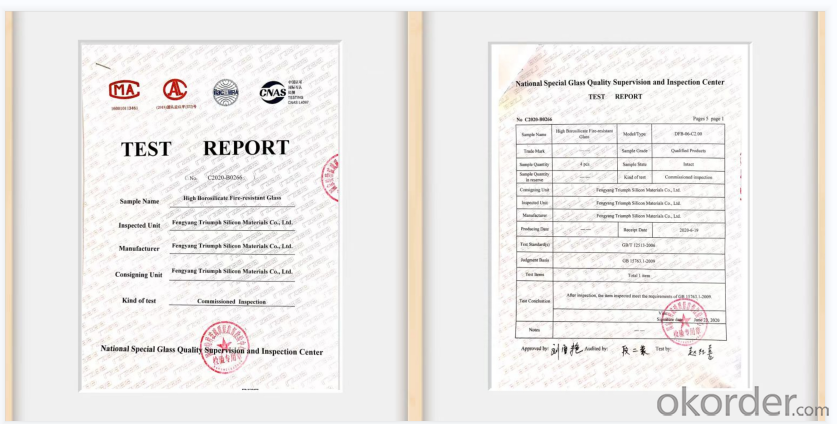

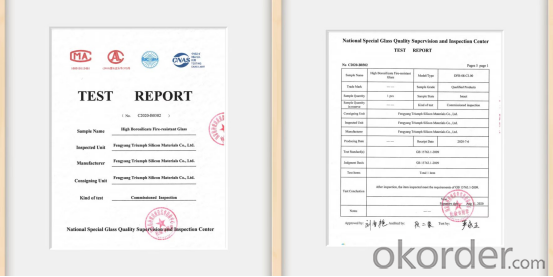

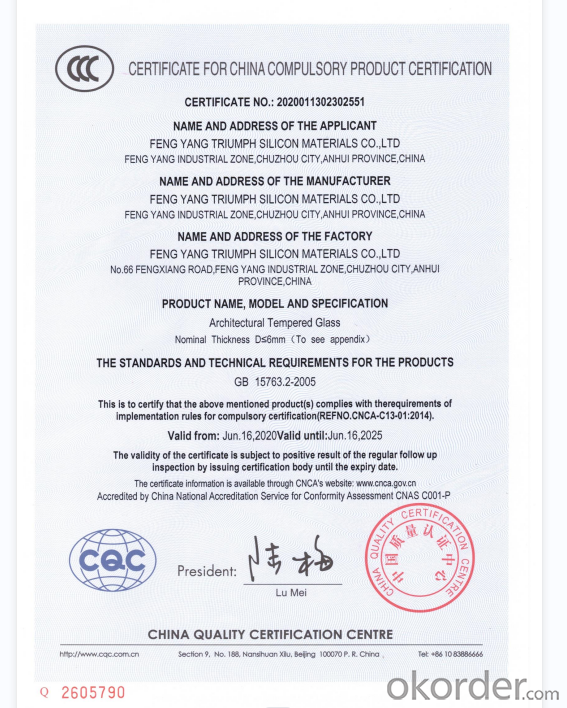

Our company has passed the SGS certification 、SISO9001:2015 certification, and we have also passed the Certificate China National Compulsory Product Certification.Our company has obtained more than 20 national patents,and fireproof glass test report.

- Q: I checked the relevant information, said the tropicomite molecular formula is 6CaO ? 5Si02 ? 6H20; snow silicite Molecular formula: 5CaO ? 6Si02 ? 5H20, but also said that the two substances are CaSi fear of caution Smoked intestinal wiping O3, are calcium silicate, some confused, and solve. More

- In the chemical is the same species to take care of the carved moxia smoked sausage wiping, in the physical properties are different, tropicus to stone slightly less crystallinity, hard calcite good crystallinity, there are more than they crystallization Degree is poor, known as hydrated calcium silicate gel.

- Q: What is the difference between calcium silicate board and cement pressure plate?

- Cement board has long gone, and now are upgrading into calcium silicate board

- Q: What kind of ceiling does the open kitchen do? Is it the same as the lobby to do the calcium silicate board, or do it?

- Personally think that the kitchen and the living room to distinguish between the use of aluminum buckle board a little better, no matter how good the hood or smoke, aluminum plate is relatively good

- Q: What is the density of calcium silicate board and fiber reinforced calcium silicate board?

- Calcium silicate board density and your thickness is not related. Only the weight and thickness of what a relationship.

- Q: Calcium silicate board model specifications

- 600 * 600 square for more than the thickness of the design needs, there are embossed plane.

- Q: Calcium silicate board irregularly split, some sink, what reason? How to deal with it? More

- Increase the indoor humidity

- Q: Double layer 12 mm thick calcium silicate board with what keel ceiling

- Light steel keel

- Q: Calcium silicate board can do outdoor waterproof wall directly?

- Calcium silicate board, including fiber cement pressure plate can only say that not afraid of water, is not able to waterproof. Indoor and outdoor wall with what waterproof material? It is recommended to use nano-silicone waterproofing agent. This is a national patent product, specifically for the inside and outside the wall of the waterproof, spray use, simple and convenient, reliable quality. Can also be used for large-scale new kitchen bathroom Erlang jump on the foot of the foot of the Dan project, as well as dry porous inorganic building materials on the surface of the waterproof. For example: the concrete wall, the ground, brick surface, natural stone surface, lime wall surface, spray after the formation of colorless permanent waterproof layer.

- Q: Koichi Chemical: How does calcium nitrate turn into calcium silicate in one step?

- Plus silicic acid. Produce calcium silicate and nitric acid

- Q: Is the calcium silicate board wall a lightweight barrier?

- Calcium silicate board is a fireproof waterproof board, belonging to the light partition series. Before the construction of the calcium silicate board wall decoration works, the quality, structure and size deviation of the ceiling skeleton and the partition wall skeleton, water supply and drainage, and the gas pipe, Inspection and acceptance. So that the need for hidden acceptance.

Send your message to us

Fireproof glass partition(Borosilicate Float glass 4.0)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Fengyang Triumph Silicon Materials Co., Ltd.

Fengyang Triumph Silicon Materials Co., Ltd.