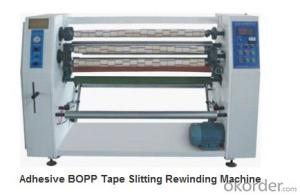

Bopp Film Slitting And Rewinding Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Bopp Film Slitting And Rewinding Machine Function

1).Have automatic constant tension unwind, multiple-stations taper tension control center + surface-reeling up, rewind and machine stopped tension keep function.

2).Slitting into suitable harness, length and neatly roll material.

3).Have automatic guiding function.

Bopp Film Slitting And Rewinding Machine Technical Parameters

1).Slitting material: 0.012-0.12mm BOPET;0.02-0.12mm CPP, BOPP film;

2).Maximum machine speed: 400m/min; Normal slitting speed 350m/min, machine running smoothly and steady, non obvious vibration or noise. Machine running smoothly and steady, non obvious vibration or noise.

3).Maximum load-bearing of unwind: 2000 kg; Maximum diameter: 1000 mm;

4).Maximum rewind diameter of rewind: 800 mm;

5).Maximum effective width: 4200mm; maximum slitting width 1200mm; maximum secondary rewinding width: 2100mm

6).Minimum slitting width: 400mm; (exceed 1200mm, we suggest use air-shaft for rewind)

7).Adaptable client's layout design required 6 inches steel tube for unwind.

8).According to client's layout design 6 inches dedicated steel tube choke plug for unwind.

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- If you are the original producers, can consider to do the initial stage through the middle of the exporter, first ensure that factory production product quality clearance, production procedures and quality control documents pass, in order to gradually establish its own customer base.

- Q: What are the main functions of packaging machinery?

- Eight main functions of packaging machinery and equipmentPacking is a necessary condition for products to enter the circulation field

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Sometimes, this wine packaging PigHead, with different types of vacuum packaging machine

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- A small object, small particle, powder, crystal, liquid, suitable for packing

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is suggested that displacement or velocity should be detected on the transport path of the membrane. Is a more reliable control signal. Of course, you can also detect the angular speed of the recovery drum, such as a code dial and other simple institutions.

- Q: What is the price of a small jujube packing machine?

- What is the price of a small jujube packing machine?

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- . This is the importance of after-sales service. Qingdao Xun packaging machine models, can meet the needs of all levels.

- Q: What are the main functions of packaging machinery and equipment?

- Sealing and other major operations, and related processes before and after,

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- There are PLC control ah, if it is fully automatic, then ask the quality of sealing ah, it is best to let manufacturers give you a live demonstration, the soft power depends on the size of the factory, ah, after-sales service ah!

- Q: What is a packaging machine?

- Packaging machinery refers to the machinery that can complete all or part of the product and commodity packaging process. The packaging process includes filling, wrapping, sealing and other main processes

Send your message to us

Bopp Film Slitting And Rewinding Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords