OPP Perforation Film Slitting Rewinding Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description

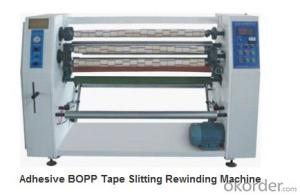

The OPP perforation film slitting rewinding machine is used to slit and rewind various large rolling materials such as paper with weight between 20g/㎡and 300g/㎡, cellophane or bill paper, double-face or single face adhesive tape, weave material, nonwoven fabric, OPP, PET, FILM, AL, PVC, copper foil and others. The slitting rewinding machine also comes with a perforator using hot needles to punch holes.

The OPP perforation film slitting rewinding machine uses automatic taper tension and central surface reeling. It has frequency converter timing to keep speedup and stable operation, also with automatic metering and alarm. The OPP perforation film slitting rewinding machine adopts A and B pneumatic shaft structure for rewinding, easy for loading and unloading.

The OPP perforation film slitting rewinding machine has photoelectric automatic error adjustment system for unwinding, atypical materials will be easy to slit. The OPP perforation film slitting rewinding machine is set with automatic waste film blowing device by circle blade and automatic input material.

2.Technical Data of OPP Perforation Film Slitting Rewinding Machine

| Model | WZFQ-1100 CP | WZFQ-1300 CP | WZFQ-1600 CP |

| Max unwinding width | 1100 mm | 1300 mm | 1600 mm |

| Max unwinding diameter | ¢ 1400 mm (700 mm option) | ¢ 1400 mm | ¢ 1400 mm |

| Min slitting width | 30 mm | 30 mm | 30 mm |

| Max rewinding diameter | ¢ 5 00 mm | ¢ 5 00 mm | ¢ 5 00 mm |

| Speed | 10-160 m/min | 10-160 m/min | 10-160 m/min |

| Precision | ± 0.2 mm | ± 0.2 mm | ± 0.2 mm |

| Total power | 12 Kw | 12.8 Kw | 16 Kw |

| Suitable power supply | 380 v/50 Hz | 380 v/50 Hz | 380 v/50 Hz |

| Weight (approx) | 3000 Kg | 3200 Kg | 3800 Kg |

| Overall dimension L × W × H (mm) | 3000 × 2200 × 1600 | 3000 × 2400 × 1600 | 3000 × 2700 × 1600 |

3. Advantages

We've been specialized in packaging machine for more than ten years, we know this product very well, and we have good finacial support from government.

4. Pictures

5. FAQ

1) What is your delivery time?

Our regular production time is over 50 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- If you are the original producers, can consider to do the initial stage through the middle of the exporter, first ensure that factory production product quality clearance, production procedures and quality control documents pass, in order to gradually establish its own customer base.

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Sometimes, this wine packaging PigHead, with different types of vacuum packaging machine

- Q: What are the packing machines?

- They make packing equipment. There are many kinds of food packaging, sealing packaging, pillow type packaging machine. I hope I can help you.

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of reducers used. What kind of machines are they under?

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine packaging production, simple operation and high degree of automation, high efficiency, low packing cost, save labor, reduce the damage and the characteristics of two pollution, by tableware shrink packaging is widely used in all kinds of, is a very mature model

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- What is the size of the parison forming pressure and the performance of the ceramic wall and floor tile products?Ceramic wall and floor tiles are usually formed by pressing. Domestic made for 30 tons, imported equipment has tons of suppression, 200 tons and 500 tons. In order to smooth accurate size, excellent products, must pay attention to the effect of powder properties and compression of products. That is to say, the quality of the floor tiles, billets, methods of preparation, and the quality of products and production scale and way of pressing machinery. As for pressing pressure, as the molding pressure decreases, the sintering shrinkage becomes smaller and the water absorption rate becomes smaller, the durability of the product should be improved. It should be noted that the pressure should not be too high. Excessive pressure, stress, and density increase will cause unnecessary energy consumption, and cause compressed air to expand after pressure is canceled and cause excessive spalling.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- This is really not sure, it can be said that any group, as long as the packaging products are required to use packaging machinery. Most of the products are now in need of packing. So it can be said that any group.

- Q: What is the working principle of the pillow packing machine?

- The sealing form - bag two sealing, a middle sealing surface,

- Q: What are the packaging machines that use temperature control watches?

- Direct heating sealing machine, blister packing machine, plastic sealing machine, heating pot, oven, toaster and so on

- Q: What is a packaging machine?

- Well, before and after the associated processes, such as cleaning, stacking and disassembly. In addition, the package also includes the measurement or in the processes of stamp packages. Mechanical packaging products can improve productivity, reduce labor intensity

Send your message to us

OPP Perforation Film Slitting Rewinding Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords