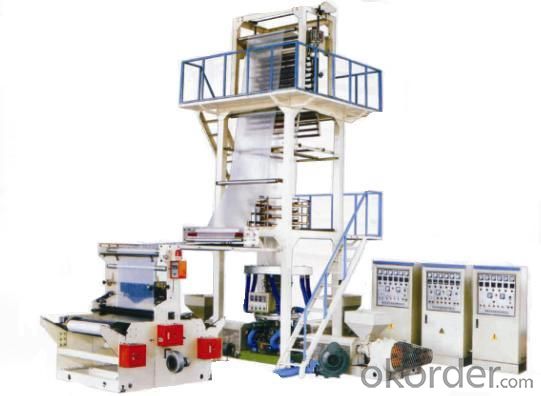

High Quality Mini Film Blowing Machine CM-M55

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 60 days/1 set set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technical Data High Quality Mini Film Blowing Machine CM-M55

Model:CM-M55

Screw Diameter: Φ55 mm

Max.folding width of film: 200-800 mm

Single-side thickness of film(mm): 0.01-0.01 mm

Max. output : 50 kg/h

Screw ratio L/D: 26:1

Main motor power (kw): 11-15 kw

Haul-off motor Power (kw): 1.1 kw

Heating power(kw): 13 kw

Overall diameter(L×W×H)(mm): 5500×2100×3500 mm

Weight(T) : 2T

MiinOrder: 1set

Package: Package wooden carton

Packing of High Quality Mini Film Blowing Machine CM-M55

Packed with wooden carton of customized size and then placed on the pallet.

Storage Of High Quality Mini Film Blowing Machine CM-M55

Storage procedures:Keep dry and cool and away from direct sunlight for quality.

Remarks of High Quality Mini Film Blowing Machine CM-M55

Due to machine development, above information may be changed at any time without prior notice. The actual specifications are according to the agreement between buyer and seller.

Service of High Quality Mini Film Blowing Machine CM-M55

We have a group of professional technicians and workers with rich experience, who are dedicated in this industry and try to offer best service to every customer. We are undertaking the idea of “reliable quality, reasonable price, and good service” to meet the needs of every customer. Your success is our goal, and your content is our hope. We keep pursuing “exact production, high-quality service”.

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- You can consider the promotion above the industry website.Plus, you're the packaging machine for candy and cookies, and of course it's the maker of candy and cookies.

- Q: What are the main plastic forming processes?

- The main equipment used for molding compression is to press and mold. The most used hydraulic press is self support hydraulic press. The tonnage varies from tens to hundreds of tons. There is a lower press and an upper press. The die used for compression molding is called pressing die. It is divided into three kinds: overflow mould, half overflow mould, no overflow mold.The main advantage of compression molding is that it can be molded into larger flat products and can be produced in large quantities. Its disadvantage is long production cycle and low efficiency.2. lamination forming. A method of combining two or more layers of material of the same or different material by heating and pressurizing with or without a binder.A layer of floating hot pressing plate is arranged between the movable plate and the fixed plate of the press.The reinforcing materials used in laminated forming are cotton cloth, glass cloth, paper and asbestos cloth. The resins are phenolic, epoxy, unsaturated polyester, and some thermoplastic resins.

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- . This is the importance of after-sales service. Qingdao Xun packaging machine models, can meet the needs of all levels.

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of reducers used. What kind of machines are they under?

- Q: Color code positioning of packaging machinery

- The main products are: packaging machinery series of quantitative packing machine, vacuum packaging machine, packing machine, strapping machine, sealing machine, bag machine, carton forming machine, packing machine, winding machine, labeling machine, stacking machine, and the design of various transmission lines; at the same time, the production and sale of packing tape, stretch film and other packaging material.

- Q: The role of packaging equipment in packaging equipment

- (4) it can reduce labor intensity and improve working conditionsThe labor intensity of manual packaging, such as volume, weight heavy manual packaging products, both the consumption of physical strength, and safety; and for small and light products, due to high frequency, easy to make the action monotonous, worker occupation disease.(5) labor protection for workersFor some serious impact on health products, such as serious dust, toxic products, irritating, radioactive products, manual packaging is a health hazard, and packaging machinery can be avoided, and can effectively protect the environment from being polluted.(6) it can reduce the packing cost and save the storage and transportation expensesFor loose products, such as cotton, tobacco, silk and hemp, the compression packing machine can reduce the volume and reduce the packing cost. At the same time, due to the reduction of large volume, in order to save storage capacity, reduce storage costs, is conducive to the transport.

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;Can use blister sealing machine or high frequency plastic welding machine hot pressing;

- Q: What's the fastest packing machine?

- Depending on the characteristics of your material, the speed is adjustable!

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Molding: mainly used for thermosetting resins. There is a special molding machine. Molding pressure is much greater than the above. The mold structure is also more complex.

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Personal advice:In this respect, I suggest you look for the factory in Dongguan, Tangxia, which is the base of vacuum bag production. By logistics or express delivery, the goods will be delivered soon!!

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 11% - 30% |

| No.of Employees in Trade Department | 5-7 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 5,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | capper, adhesive sheet machine, conveting machine, rewinder machine, slitting machine, machine for protective film |

| Product Price Range | High; Average |

Send your message to us

High Quality Mini Film Blowing Machine CM-M55

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 60 days/1 set set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords