Personalised Packaging Tape UK - BP-60 BOPP Adhesive Tape BOPP Film Water Based Acrylic

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product description

| Material: | BOPP | Use: | Carton Sealing | Adhesive Side: | Single Sided |

| Adhesive: | Acrylic | Adhesive Type: | Pressure Sensitive, Water Activated | Feature: | Waterproof |

| Design Printing: | Offer Printing | Place of Origin: | Beijing, China (Mainland) | MOQ | 1800 rolls |

2.Packaging & Delivery

Packaging Details:

1) individually wrapped,

2)6rolls/ Tower shrink/ Flat_pack,

3)about 36~100rolls/cartonDelivery Detail:

within 15 days after comfirming the deposit and packaging detail

3.Product show

4.Company information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

We specilized in Duct tape, Masking tape, Double sided tissue tape, PET tape, Foam tape, PVC tape, Warning tape, Fiberglass tape…Now we have exported our products to over 30 countries and regions like Europe ,South / North America ,Southeast Asia etc and gained customer's respect and continued businesses. Based on our good quality , reasonable price, good after-sale service, we enjoyed good reputation in the international market.

Warmly welcome your any inquiries or request ! You will be impressed by our superior quality, quick delivery date and attractive price. Contact us now!

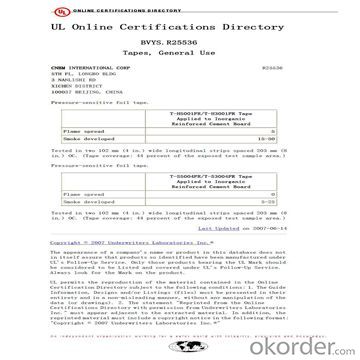

5.Our certification

6.Our services

1.OEM Service

Your own design is appreciated; we can make the approval sample according to your golden sample.

2. QC Service

a) Before the order to be confirmed, we should check the material & color of fabric by sample which should be strictly.

b) We will be tracing the different phase of production from the beginning.

c) Every bad quality will be checked & cleaned before packing.

d) Before delivery clients could send one QC or point the third party to check the quality.

e) We will try our best to help clients when problem occurred.

3. After-sale Service

a) EXW, FOB, C&F are also available for us.

b) If the products need certificate, we can also provide.

7.FAQ:

Q1: Are you manufacturer or trading company?

A: We are professional Manufacturer.

Q2: Can I use our own designing?

A: Yes, size, printing, color, paper core, logo, carton box can be customized.

Q3: May I have samples?

A: Yes, Free samples available and freight collect by DHL, FEDE

- Q: Can packaging tape be used for sealing cloth or fabric items?

- Packaging tape has the capability of sealing cloth or fabric items. Its design ensures strength and adhesive properties, making it efficient for securing and sealing different materials, such as cloth and fabric. When it comes to packages containing cloth or fabric items, packaging tape becomes particularly handy as it ensures a secure closure that prevents any potential damage or loss during transportation or storage. Furthermore, the transparency of packaging tape allows for effortless identification of the contents while maintaining the overall appearance of the cloth or fabric item intact.

- Q: Can packaging tape be used for sealing plastic pet carriers?

- Yes, packaging tape can be used for sealing plastic pet carriers. Packaging tape is designed to securely seal boxes and packages, and it provides a strong adhesive bond. When applied properly, it can effectively seal the openings of plastic pet carriers, ensuring that your pet is safely contained inside. However, it is important to ensure that the tape is applied evenly and securely to prevent any gaps or openings that your pet may be able to escape from. Additionally, it is recommended to check the tape periodically to make sure it remains intact and reapply if necessary.

- Q: Can packaging tape be used for sealing packages with automotive parts or accessories?

- Yes, packaging tape can be used for sealing packages containing automotive parts or accessories. It provides a strong and secure seal to protect the contents during transportation. However, it is recommended to use packaging tape specifically designed for heavy-duty or industrial purposes to ensure optimal durability and adhesion for automotive packages.

- Q: What are the considerations for using packaging tape on textured surfaces?

- When using packaging tape on textured surfaces, there are a few considerations to keep in mind. Firstly, the texture of the surface can affect the adhesion of the tape. Textured surfaces typically have uneven or rough areas, which may make it difficult for the tape to adhere securely. It is important to choose a packaging tape that is specifically designed for textured surfaces. These tapes usually have a stronger adhesive that can better stick to uneven surfaces, ensuring that the tape will stay in place. Another consideration is the durability of the tape. Textured surfaces can be more abrasive than smooth surfaces, which can cause the tape to wear out more quickly. It is important to select a packaging tape that is made from a durable material, such as reinforced or heavy-duty tape. These types of tape are designed to withstand more wear and tear, providing a longer-lasting bond on textured surfaces. Additionally, the texture of the surface can also affect the appearance of the tape. Since textured surfaces are not smooth, the tape may not lay flat and can create air pockets or wrinkles. This can make the package look untidy or unprofessional. To improve the appearance, it may be necessary to use extra tape or apply it in a way that smooths out any unevenness. Lastly, it is important to consider the removal of the tape from textured surfaces. Textured surfaces can make it more difficult to remove the tape cleanly without leaving behind any residue. To prevent damage to the surface or any sticky residue, it is recommended to test the tape on a small, inconspicuous area before fully applying it. If the tape does leave residue, there are adhesive removers available that can help safely remove any remaining residue. In summary, when using packaging tape on textured surfaces, it is important to choose a tape specifically designed for uneven surfaces, select a durable tape that can withstand the texture, consider the appearance of the tape on the textured surface, and be cautious of any potential residue left behind when removing the tape.

- Q: How do I prevent packaging tape from becoming too sticky?

- To avoid packaging tape becoming excessively sticky, there are several precautions you can take: 1. Keep the tape in a cool and dry location: Excessive heat and humidity often lead to the adhesive on packaging tape becoming stickier. It is important to store the tape in a cool and dry environment to maintain its proper consistency. 2. Prevent contact with dust and debris: Dust and debris easily adhere to the adhesive side of the tape, increasing its stickiness. Keep the tape away from dusty surfaces and ensure that the areas where you plan to apply the tape are clean and free from loose particles. 3. Utilize a tape dispenser: A tape dispenser aids in controlling the amount of tape you use and prevents excessive stickiness. It allows for a more precise application, ensuring that you do not use more tape than necessary. 4. Avoid excessive stretching of the tape: Stretching the tape excessively while applying it can cause it to become stickier. Apply the tape smoothly without pulling or stretching it too much, as this can activate the adhesive further. 5. Consider using low-tack or removable tape: If you frequently encounter problems with sticky packaging tape, you may consider using low-tack or removable tape. These types of tape have less aggressive adhesive properties and are easier to remove without leaving sticky residue. By following these guidelines, you can maintain the desired level of stickiness on your packaging tape and streamline your packaging process.

- Q: Does packaging tape come in different colors for organization purposes?

- Yes, packaging tape does come in different colors for organization purposes. Many companies offer packaging tape in various colors such as red, blue, green, yellow, and black. These different colors can be used to categorize and organize different types of packages or to differentiate between shipments going to different destinations. It can be particularly useful in warehouses or shipping departments where multiple packages need to be identified and sorted easily. Additionally, colored packaging tape can also be used for decorative purposes, such as gift wrapping or creating visually appealing packaging for retail products.

- Q: How do I prevent packaging tape from leaving a sticky residue?

- To prevent packaging tape from leaving a sticky residue, there are a few simple steps you can take. 1. Choose the right type of tape: Opt for high-quality packaging tape that is specifically designed to leave minimal residue. Look for tapes with a low-tack adhesive or those labeled as residue-free. 2. Clean the surface: Before applying the tape, make sure the surface is clean and dry. Wipe away any dust, dirt, or grease using a mild detergent or a rubbing alcohol solution. This will help the tape adhere better and reduce the chances of residue formation. 3. Test in a small area: If you're unsure about the tape's residue potential, it's always wise to test it in a small, inconspicuous area first. Apply a small piece of tape and let it sit for a few hours or overnight. After removing it, check if any sticky residue is left behind. If not, you can proceed with confidence. 4. Remove tape gently: When removing the tape, do it slowly and at a low angle, preferably parallel to the surface. Pulling it too quickly or at a high angle can increase the chances of leaving behind sticky residue. Take your time and be patient to avoid any damage or residue. 5. Use heat or solvent if needed: In case some residue remains, you can try using gentle heat or certain solvents to remove it. For heat, you can use a hairdryer on low setting to warm up the residue and then wipe it away with a clean cloth. If needed, you can also try using rubbing alcohol, white vinegar, or adhesive remover by applying a small amount on a cloth and gently rubbing the residue until it dissolves. By following these tips, you should be able to prevent packaging tape from leaving a sticky residue and maintain a clean surface.

- Q: Can packaging tape be used for sealing packages with perishable items?

- Using packaging tape to seal packages with perishable items is not recommended. Although it may create a temporary seal, it is not intended to withstand the specific difficulties that accompany packaging perishable goods. Items that can spoil, such as food or flowers, necessitate specialized packaging materials that offer insulation, temperature control, and protection against moisture or air leakage. These materials are purposely designed to safeguard perishable items throughout transportation and storage. Consequently, it is advisable to utilize suitable packaging materials like insulated bags, coolers, or specialized packaging solutions to seal packages containing perishable items, guaranteeing their freshness and quality.

- Q: Is packaging tape safe to use on painted surfaces?

- Packaging tape is generally safe to use on painted surfaces, but there are a few factors to consider. Firstly, it is important to ensure that the paint is fully cured before applying any tape. This typically takes around 30 days, depending on the type of paint used. Applying tape to fresh or uncured paint can cause damage when the tape is removed. Secondly, the type of tape used can also make a difference. Most packaging tapes are designed to be easily removable without leaving residue or causing damage to surfaces. However, some low-quality tapes or tapes with strong adhesives may leave behind sticky residue or even peel off the paint when removed. It is recommended to use high-quality packaging tape that is specifically labeled as safe for painted surfaces. To be on the safe side, it is always a good idea to test the tape on a small, inconspicuous area of the painted surface before applying it extensively. This will help you ensure that the tape does not cause any damage or leave residue behind. If there are any concerns, it is advisable to consult the manufacturer's instructions or seek professional advice. Overall, when used properly and on fully cured paint, packaging tape should be safe to use on painted surfaces. However, it is important to exercise caution and choose the right tape to prevent any potential damage.

- Q: Can packaging tape be used for sealing storage containers?

- Yes, packaging tape can be used for sealing storage containers.

Send your message to us

Personalised Packaging Tape UK - BP-60 BOPP Adhesive Tape BOPP Film Water Based Acrylic

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords