BMP Z80 Rolled Steel Coil for Sandwich Pane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

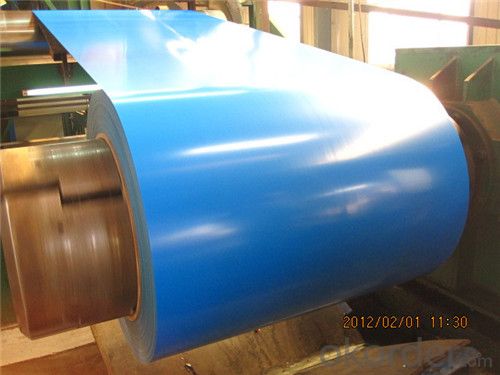

Structure of BMP Z80 Rolled Steel Coil for Sandwich Panel

Description of BMP Z80 Rolled Steel Coil for Sandwich Panel

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of BMP Z80 Rolled Steel Coil for Sandwich Panel

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of BMP Z80 Rolled Steel Coil for Sandwich Panel

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; gas tank;pentane tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of BMP Z80 Rolled Steel Coil for Sandwich Panel

Product | BMP Z80 Rolled Steel Coil for Sandwich Panel |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 700-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled, slight oiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of BMP Z80 Rolled Steel Coil for Sandwich Panel

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Our delivery time is around 30 day after order confirmed.

3. How to make sure the quality of the order?

We have quality control team over 40 QC every link from raw material to final product we have strict quality test.

4, What kind payment can you accept.

We accept T/T, and LC at sight, L/C 30days

- Q: What are the different types of steel coil welding methods?

- There are three main types of steel coil welding methods: butt welding, lap welding, and flash welding. Butt welding involves joining two ends of steel coils by aligning them and welding them together. Lap welding, on the other hand, involves overlapping the ends of the coils and welding them together. Flash welding is a method where the ends of the coils are placed in contact with each other and a high electric current is passed through them to create a weld.

- Q: How are steel coils used in various industries?

- Steel coils are used in various industries for their durability and versatility. They are commonly used in automotive, construction, and manufacturing industries for making structures, machinery, and appliances. Steel coils are also utilized in the energy sector for producing power generation equipment and in the transportation industry for making ships and railcars. Overall, steel coils play a significant role in providing strength and reliability in a wide range of industrial applications.

- Q: How are steel coils used in the production of roofing materials?

- Steel coils are used in the production of roofing materials as they are rolled out and cut into specific dimensions to create metal roofing sheets. These coils provide a sturdy and durable base material that is resistant to weather conditions, ensuring long-lasting and reliable roofing solutions.

- Q: Can steel coils be coated with weather-resistant materials?

- Yes, steel coils can be coated with weather-resistant materials such as zinc, aluminum, or organic coatings to enhance their resistance to corrosion and exposure to harsh weather conditions.

- Q: How are steel coils inspected for color consistency?

- Steel coils are inspected for color consistency using a variety of methods to ensure that the final product meets the desired specifications. One common method is visual inspection, where trained inspectors examine the steel coils under controlled lighting conditions to detect any variations in color. This is done by comparing the color of each coil to a standard color chart or a previously approved sample. Any discrepancies are noted and further analysis is conducted. Additionally, advanced technologies such as spectrophotometers may be employed to measure the color of the steel coils objectively. Spectrophotometers use light to measure the reflective properties of the steel surface, allowing precise color analysis. The obtained color data is then compared to the specified color range, and any deviations are flagged for further investigation. Furthermore, some manufacturers may use automated color measurement systems, such as colorimeters or color cameras, to inspect steel coils for color consistency. These systems can quickly and accurately assess the color of each coil, ensuring uniformity across the entire batch. Overall, the inspection of steel coils for color consistency involves a combination of visual inspection, spectrophotometry, and automated color measurement systems. This comprehensive approach helps to guarantee that the steel coils meet the required color standards, providing consistent and high-quality products to customers.

- Q: Can steel coils be coated with noise-reducing materials?

- Yes, steel coils can be coated with noise-reducing materials.

- Q: What are the different methods of steel coil surface cleaning?

- Some of the different methods of steel coil surface cleaning include pickling, shot blasting, and chemical cleaning. Pickling involves immersing the steel coil in an acid solution to remove oxides and scales. Shot blasting uses high-speed particles to remove rust, scale, and paint from the surface. Chemical cleaning involves using specialty chemicals to dissolve contaminants and restore the steel coil's surface.

- Q: can steel boil and turn into a gaseous state?? if so how hot does it have to be for it to boil

- well what for yo? melting point of steel is 800 degrees, oxidation being 1400 degrees.

- Q: What are the dimensions of steel coils used in automotive part manufacturing?

- The dimensions of steel coils used in automotive part manufacturing can vary depending on the specific application and requirements. However, common dimensions for steel coils used in this industry range from 0.5mm to 3mm in thickness and 600mm to 2000mm in width. The length of the coils can also vary, typically ranging from 1000mm to 6000mm.

- Q: How do steel coils contribute to the manufacturing of steel furniture?

- Steel coils play a crucial role in the manufacturing of steel furniture. These coils, which are made of high-quality steel, serve as the primary raw material for the production of various furniture items. Firstly, steel coils are used to create the framework and structure of steel furniture. These coils can be easily cut, shaped, and welded into various shapes and sizes, allowing manufacturers to create sturdy and durable furniture frames. The flexibility of steel coils enables the production of furniture with intricate designs and unique shapes, providing both functional and aesthetic value. Additionally, steel coils are also used in the production of springs for furniture such as sofas and chairs. The elasticity and strength of the steel coils make them ideal for creating comfortable and supportive seating options. These coils are carefully formed and integrated into the furniture, ensuring that the seating surface provides the necessary resilience and flexibility for a comfortable experience. Moreover, steel coils contribute to the overall durability and longevity of steel furniture. Steel is known for its high tensile strength and resistance to wear and tear, making it an excellent choice for furniture that is subjected to heavy use and weight load. The use of steel coils ensures that the furniture can withstand years of regular use without compromising its structural integrity. Furthermore, steel coils are often treated with various finishes and coatings to enhance their appearance and protect them from corrosion. These coatings can be applied to the coils before they are shaped into furniture components, ensuring that the final product maintains its aesthetic appeal and remains resistant to rust and other forms of damage. In conclusion, steel coils are an essential component in the manufacturing of steel furniture. They provide the necessary strength, flexibility, and durability required to create sturdy furniture frames, comfortable seating surfaces, and long-lasting products. Without steel coils, the production of steel furniture would not be possible, and the quality and performance of the final products would be compromised.

Send your message to us

BMP Z80 Rolled Steel Coil for Sandwich Pane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords