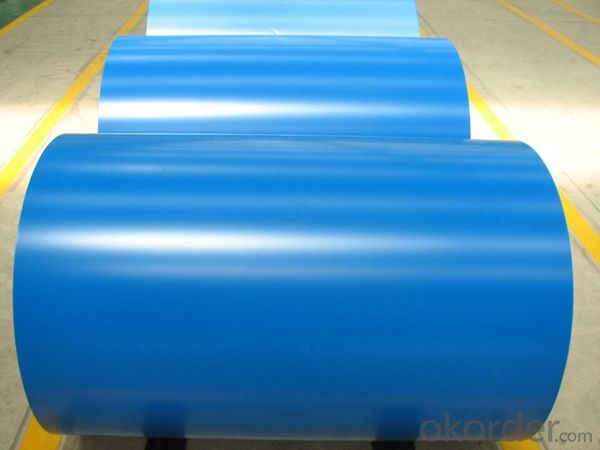

5052 H32 Aluminum Alloy Coil - Blue Color Coating for Outdoor Wall System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Blue Color Coating Aluminum Coil for Out Door Wall System

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Blue Color Coating Aluminum Coil for Out Door Wall System

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Blue Color Coating Aluminum Coil for Out Door Wall System

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Blue Color Coating Aluminum Coil for Out Door Wall System

6. Package and shipping of Blue Color Coating Aluminum Coil for Out Door Wall System

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the mass of 3.45 moles of Aluminum sulfate?Can u explain how?

- Aluminum sulfate is Al2S3, so you got two atoms of aluminum and three of oxygen. Hence the molar mass of aluminum sulfate is: 2X16 (two times molar mass of oxygen) + 3X32 (three times molar mass of sulfur). Keep in mind that the molar mass of an elements equals its mass number. We have 128 grams per mole or 128 pounds per lb-mol. Since you have 3.45 moles of Al2S3 you just have to do 3.45 times 128 = 441.6 grams

- Q: What are the potential applications of coil-anodized aluminum coils?

- Coil-anodized aluminum coils have a wide range of potential applications due to their durability, versatility, and aesthetic appeal. Some of the common applications include architectural cladding, roofing, signage, facade panels, interior decoration, automotive trim, and electronics casings. The anodized coating provides enhanced corrosion resistance, weatherability, and color stability, making it suitable for both indoor and outdoor use. Additionally, the ability to create various finishes and textures further expands the possibilities for using coil-anodized aluminum coils in different industries.

- Q: Can aluminum coils be used in food processing or packaging applications?

- Aluminum coils have proven to be highly effective in food processing and packaging. The food industry extensively utilizes aluminum due to its remarkable qualities such as resistance to corrosion, lightweight nature, and exceptional heat conductivity. This versatile material is commonly employed in food wrapping, the creation of food containers, and in the form of coils for various food processing needs. When it comes to packaging perishable food items like meat, dairy products, and beverages, aluminum coils are frequently employed. These coils can be effortlessly molded into diverse shapes and sizes to meet specific packaging requirements. The outstanding barrier properties of aluminum effectively shield the food from moisture, oxygen, and light, thereby ensuring extended shelf life and preserving food quality. In food processing, aluminum coils find application in a wide range of equipment including heat exchangers, evaporators, condensers, and refrigeration systems. The remarkable thermal conductivity of aluminum enables efficient heat transfer, making it suitable for tasks that necessitate precise temperature control. Furthermore, aluminum is completely non-toxic and does not react with food, making it an exceptionally safe and hygienic choice for food processing and packaging. Additionally, its recyclability renders it an environmentally friendly option. Overall, the widespread acceptance and utilization of aluminum coils in food processing and packaging is attributed to their versatility, durability, and ability to maintain the quality and safety of food products.

- Q: How much does it cost to use fluorocarbon paint for aluminum coil roller coating?

- Fluorocarbon paint can be divided into fluorocarbon paint for exterior wall, aluminum fluorocarbon paint, metal fluorocarbon paint and steel structure fluorocarbon paint according to usages. It can also be divided into national standard product and non-national standard product according to industrial standards.

- Q: How do aluminum coils withstand extreme weather conditions?

- Due to the unique properties of aluminum, aluminum coils can endure harsh weather conditions. Firstly, aluminum's lightweight nature allows it to remain flexible and resistant to bending or warping when faced with strong winds or heavy snow loads. As a result, aluminum coils are less likely to be damaged during extreme weather events like hurricanes or blizzards. Moreover, aluminum possesses a high resistance to corrosion. When exposed to air, it forms a protective oxide layer on its surface, preventing rusting or deterioration caused by moisture or severe weather conditions. This protective layer acts as a barrier against elements such as rain, snow, or saltwater, making aluminum coils highly durable and long-lasting. Additionally, aluminum exhibits high thermal conductivity, enabling it to efficiently dissipate heat. This property ensures that aluminum coils effectively transfer heat away from the system, preventing overheating and potential damage during hot weather conditions. Furthermore, the efficient dissipation of heat contributes to the energy efficiency of aluminum coils. Lastly, aluminum is a non-magnetic material, rendering it unaffected by electromagnetic interference or lightning strikes. This quality makes aluminum coils safe and dependable in areas prone to electrical storms or high levels of electromagnetic activity. To summarize, aluminum coils are designed to endure extreme weather conditions due to their lightweight, corrosion-resistant, thermally conductive, and non-magnetic properties. These characteristics make aluminum coils highly durable, dependable, and suitable for various applications, including HVAC systems, automotive cooling, and electrical wiring.

- Q: Briefly describe the process of aluminum production from bauxite. Describe the electrolyte and write the anode and cathode half-reactions.

- Bauxite is purified by washing with sodium hydroxide and then seeding with dry ice. The purified aluminium oxide is then dissolved in molten cryolite at 900 degrees C (the electrolyte). It is electrolysed with grapite anodes and a graphite cathode that acts as the vessel for the reaction. Anode; 2 O2- - O2(g) + 4e Cathode: Al3+ + 3e - Al(l)

- Q: This question asks for a brief explanation of the process involved in the manufacturing of aluminum coils.

- <p>Aluminum coil is made through a series of processes starting with the melting of aluminum ingots or scrap. The molten aluminum is then poured into a casting machine where it's cooled and solidified into large slabs. These slabs are then heated and passed through a series of rolling mills to reduce their thickness and achieve the desired coil gauge. The rolling process is often hot or cold, depending on the final application of the coil. After rolling, the aluminum is coiled into rolls and may undergo additional treatments like annealing to improve its properties. Finally, the aluminum coil is cleaned, inspected, and shipped for use in various industries such as construction, automotive, and packaging.</p>

- Q: What are the various techniques used in the manufacturing process to create insulation for aluminum coils?

- <p>Aluminum coil insulation is produced using several methods, including lamination, extrusion, and coating. Lamination involves stacking thin sheets of aluminum with insulating material between them. Extrusion is a process where aluminum and insulation materials are pushed through a die to create a continuous profile. Coating methods apply a layer of insulating material directly onto the aluminum coil surface. These methods ensure the insulation maintains its properties under varying conditions, providing electrical isolation and protection against environmental factors.</p>

- Q: What are the different coil handling equipment options for aluminum coils?

- There are several coil handling equipment options available for handling aluminum coils, depending on the specific requirements and preferences of the user. Some of the common options include: 1. Coil Lifters: Coil lifters are specially designed lifting devices that can safely and efficiently handle aluminum coils. They typically consist of a set of clamps or hooks that securely hold the coil and are attached to a lifting mechanism. Coil lifters can be manually operated or powered by electricity or hydraulics, providing ease of use and increased productivity. 2. Coil Tippers: Coil tippers are used to rotate or tilt aluminum coils to facilitate loading, unloading, or positioning. They are typically equipped with adjustable arms or clamps that hold the coil in place during rotation. Coil tippers can be controlled manually or using hydraulic or electric systems, allowing for precise and controlled movements. 3. Coil Cars: Coil cars are specially designed transport vehicles that are used to move aluminum coils within a manufacturing facility or between different areas. They are equipped with a platform or carriage on which the coil is placed, and can feature various mechanisms for loading, unloading, and positioning the coil. Coil cars can be manually operated or powered by electricity or hydraulics for increased efficiency. 4. Coil Turnstiles: Coil turnstiles are used to safely and efficiently store and retrieve aluminum coils in a vertical position. They typically consist of a rotating drum or spool that can hold multiple coils, allowing for easy access and retrieval. Coil turnstiles can be manually operated or powered by electricity or hydraulics, providing quick and convenient storage solutions. 5. Coil Cradles: Coil cradles are used to support and protect aluminum coils during storage or transportation. They typically consist of a sturdy frame or structure with adjustable arms or supports that securely hold the coil in place. Coil cradles can be customized to accommodate different coil sizes and weights, ensuring safe and stable handling. Overall, these coil handling equipment options provide various solutions for efficiently and safely handling aluminum coils, helping to streamline manufacturing processes and improve productivity. The choice of equipment would depend on factors such as the size and weight of the coils, the specific requirements of the operation, and the available budget.

- Q: Hi i need to know what will happen to the impact strength of aluminum 2024 reinforced with Silicon carbide is treated to cryogenic temperature (nearly -200C). Will impact strength increase or decrease. Also will the impact strength vary with respect to the percentage of Silicon carbide.

- Aluminum 2024 doesn't have a transition temperature, it absorbs about 18n-m impact strength (via charpy tests I ran three weeks ago at my College course). This was constant between -150?C to +150°C (liquid nitrogen to a furnace). This excerpt from wiki: Cutting tools In 1982 at the Oak Ridge National Laboratories, George Wei, Terry Tiegs, and Paul Becher discovered a composite of aluminium oxide and silicon carbide whiskers. This material proved to be exceptionally strong. Development of this laboratory-produced composite to a commercial product took only three years. In 1985, the first commercial cutting tools made from this alumina and silicon carbide whisker-reinforced composite were introduced by the Advanced Composite Materials Corporation (ACMC) and Greenleaf Corporation. Leads me to believe it depends on how you mix the material in would make a difference. Silicon Carbide and aluminum make very strong tools, but would make it more brittle. The ceramic in a metallic crystal lattice (metal is a crystalline structure) would allow more voids to coalesce leading to a brittle fracture, but the initial strength would be improved because of substitution dislocations in the crystal structure (it would be more rigid, stronger, but more prone to sudden failure). Silicon carbide has low thermal expansion coefficient compared to aluminum also so when it gets really cold the aluminum would contract around the particles increasing the strength, but again, reducing ductility and causing fractures to occur more rapidly. Anyways, very interesting, you should do a bit of research on your own after this as I gave you some good places to work from (and I'm sure plenty of words to look up ;D )

Send your message to us

5052 H32 Aluminum Alloy Coil - Blue Color Coating for Outdoor Wall System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords