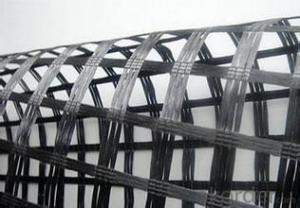

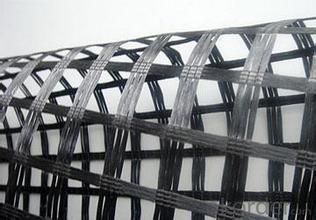

Naue Biaxial Uniaxial Bitumen Coated Black Fiberglass Geogrids

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Description

Fiberglass Geogrid is widely used in civil construction over the whole world. It is manufactured on the basis of high-impact fiberglass.

Fiberglass Geogrid are used as reinforcement materials on mellow soils for railway and car roads, parking places, landing grounds and for the reinforcement of bridge piers, slopes and earth banks, for erosion protection of slopes.

Overall features & benefits

High tensile strength in both the warp and weft directions;

Low elongation;

Good anti-age and alkali-resistance;

Reduce construction cost, extend service life of road and prevent deflection cracks.

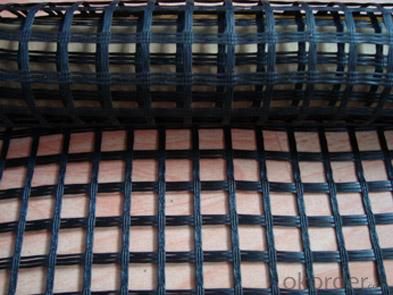

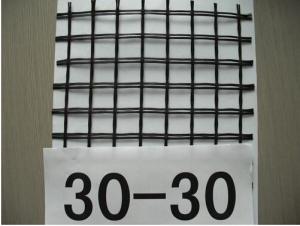

Specification

Intensity: 25, 30,40,50,80,100 KN/M

Width: 1-6M Length: 50-100 M

Application

Reinforcement of highways slopes and higher steepness slopes fixation;

Bed fixation of the various types of road surfacing;

Reinforcement of littoral zone of water reservoirs and Greek beds;

Fixation of the railroad cone slopes;

Support wall construction.

Packaging & Delivery

| Packaging Details: | Rolls |

| Delivery Detail: | 20 Days |

Detiled Data

Tensile | Warp | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥120 |

Strength | |||||||

(KN) | Weft | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥120 |

Elogation | Fiberglass | <4 % | 4 % | 4 % | 4 % | 4 % | 4 % |

Polyester | <13%< span=""> | 13% | 13% | 13% | 13% | 13% | |

Mesh size(mm) | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | |

25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | ||

42×42 | 42×42 | 42×42 | 42×42 | 42×42 | 42×42 | ||

50×50 | 50×50 | 50×50 | 50×50 | 50×50 | 50×50 | ||

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | |

(Fiberglass) | |||||||

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature | Fiberglass | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 |

Resistant (°C) | Polyester | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 |

Resin | Fiberglass | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 |

Content (%) | polyester | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% |

F&Q

1 How about the delivery time? Lead time since receipt of 30% T/T deposit payment: 3 weeks.2 What kind of payments does jenor support? T/T 3

What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4

How to deal with the sample charge?

Accordeing to our company policy, the samples are free, we only charge the freight fee.

And we will return the freight fee If you set the order .

5

Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6

Can you tell me your main customers?

That's our customers' privacy, we should protect their information.

At the same time, please rest assured that your information is also safe here.

- Q: What is the meaning of two-way 50kN geogrid

- The code is GSL, GSL50 represents the longitudinal and transverse tensile strength more than 50KN of plastic geogrids.

- Q: What are the physical properties of Geosynthetics

- What are the physical properties of geosynthetics? 1, thickness: the thickness of geosynthetics mm. The variation of thickness has a great influence on the porosity, permeability and filtration properties of the fabric. Commonly used the thickness of all kinds of geosynthetics: geomembrane 0.25 ~ 0.75mm, the thickest of up to 2 ~ 4mm;

- Q: What are the benefits of using geogrids in pavement construction?

- Geogrids offer several benefits in pavement construction, including improved stability and load-bearing capacity, reduced cracking and rutting, increased pavement lifespan, and cost savings. By reinforcing the soil or aggregate base, geogrids distribute the load more evenly, preventing the formation of potholes and reducing maintenance requirements. Additionally, they enhance the overall structural integrity of the pavement, making it more resistant to heavy traffic and environmental factors such as freeze-thaw cycles. Ultimately, utilizing geogrids in pavement construction leads to longer-lasting, more durable roads with reduced maintenance needs, resulting in cost savings over time.

- Q: How do geogrids improve the performance of retaining walls in earthquake-prone areas?

- Geogrids improve the performance of retaining walls in earthquake-prone areas by providing reinforcement and stability. These high-strength geosynthetic materials are placed within the soil behind the retaining wall, which helps to distribute the forces generated during an earthquake more evenly. This reduces the pressure on the wall and enhances its resistance to lateral movement and potential failure. Geogrids also increase the overall strength and load-bearing capacity of the soil, making the retaining wall more resilient against seismic forces.

- Q: What are the factors that affect the installation and survivability of geogrids in harsh environments?

- The factors that affect the installation and survivability of geogrids in harsh environments include the quality of the geogrid material, proper installation techniques, the severity of the environmental conditions, and the level of maintenance and monitoring. The choice of a high-quality geogrid material that can withstand the specific conditions is crucial. Proper installation techniques, such as adequate compaction, correct anchoring, and suitable soil preparation, ensure the geogrid's stability and longevity. The severity of the environmental conditions, such as extreme temperatures, high winds, or corrosive elements, can also impact the geogrid's performance. Regular maintenance and monitoring, including inspections and timely repairs, are essential to enhance the survivability of geogrids in harsh environments.

- Q: I asked what the raw materials needed for the production were, for example, what the green mesh was made of

- Building safety net, also can be called the steel plastic geogrid. Steel grating and construction safety net (protective net) welded together

- Q: Why steel plastic geogrid in the test, will choose to peel out a single wire test? What are the causes and sources of this method?

- Because the main force borne by the steel wire, if it is false, the consequences can be disastrous ah!

- Q: Can geogrids be used in streambank stabilization applications?

- Yes, geogrids can be used in streambank stabilization applications. Geogrids are commonly used in these applications to reinforce and stabilize slopes and banks, preventing erosion and soil movement. They provide strength and support to the soil, allowing vegetation to establish and grow, further enhancing the stability of the streambank.

- Q: How do geogrids improve the performance of geosynthetic-reinforced slopes in liquefaction-prone areas?

- Geogrids improve the performance of geosynthetic-reinforced slopes in liquefaction-prone areas by providing additional strength and stability. These synthetic materials are used to reinforce the soil and prevent it from shifting or sliding during liquefaction events. The geogrids act as a reinforcement layer within the soil, increasing its shear strength and reducing the potential for slope failure. Additionally, geogrids help to distribute loads more evenly across the slope, reducing stress concentrations and improving overall slope stability in liquefaction-prone areas.

- Q: Panzhihua steel plastic composite geogrid manufacturers, how much money, where to sell

- It will not be affected by acid and alkali, salt solution and oil at normal temperature

Send your message to us

Naue Biaxial Uniaxial Bitumen Coated Black Fiberglass Geogrids

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords