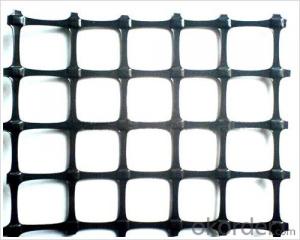

Biaxial Geogrids for Roadbed Reinforcement - Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

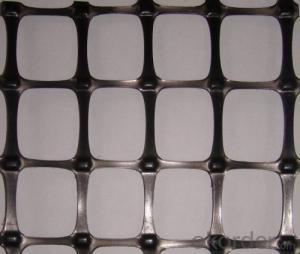

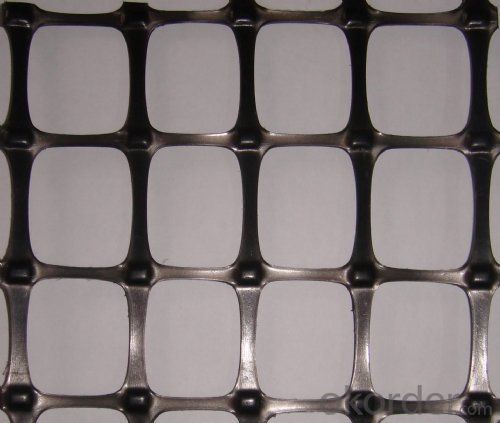

Our niaxial geogrids are made from polyester yarn, knitted or woven into a stable structure and have a PVC or polymeric coating. These flexible, user-friendly geogrids are inert to biological degradation and resistant to creep, strain and naturally found chemicals.

Biaxial geogrids are designed to have roughly the same tensile strength in both directions and to distribute loads over a wider area, increasing the load capacity of the soil. Base reinforcing geogrids interlock with the aggregate to confine the base and reinforce the subgrade. In paved or unpaved applications, they reduce rutting and help maintain the desired aggregate depth.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

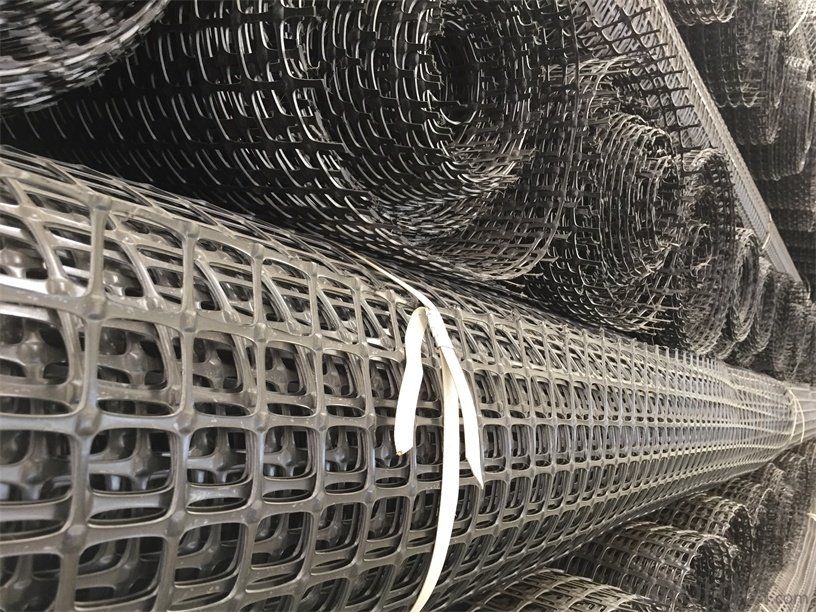

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Classification and characteristics of geogrids

- Characteristics of glass fiber geogrid:1, high tensile strength, low elongation - fiberglass geogrid with glass fiber as raw material, has a high resistance to deformation, fracture elongation rate of less than 3%.2, no long-term creep as reinforcing material, have in long-term load under the condition of deformation resistance that the creep resistance is extremely important, glass fiber does not creep, which ensure product can maintain long-term performance.3, thermal stability - the melting temperature of glass fiber above 1000 degrees Celsius, which ensures that the fiberglass geogrid in paving operations to withstand the heat stability.4, mixed with asphalt compatible materials - glass fiber geogrid treatment process after coating is designed for asphalt mixture, every fiber is fully coated with high compatibility with asphalt, so as to ensure that the glass fiber geogrid in the asphalt layer and not in isolation of asphalt mixture but, firmly together.5, physical and chemical stability, through special postprocessing agent coating, glass fiber geogrid can resist all kinds of physical and chemical erosion wear, can resist biological erosion and climate change, ensure that its performance is not affected.6, lock and limit the aggregate because of glass fiber geogrid is mesh structure, aggregate in asphalt concrete can be run through them, thus forming a mechanical interlock. This restriction hinders the movement of aggregates, so that the asphalt mixture in the case of load can achieve better compaction state, higher load capacity, better load transfer performance and smaller deformation.

- Q: Can geogrids be used in temporary construction haul roads?

- Yes, geogrids can be used in temporary construction haul roads. Geogrids are commonly used to reinforce and stabilize the soil, providing additional strength and load-bearing capacity. They can effectively distribute the load from construction vehicles, reduce rutting, and increase the lifespan of temporary roads.

- Q: Can geogrids be used in temporary erosion control applications?

- Yes, geogrids can be used in temporary erosion control applications. They are often used to stabilize and reinforce soil in areas prone to erosion, such as construction sites or temporary access roads. Geogrids provide strength and stability to the soil, preventing erosion and promoting vegetation growth.

- Q: Are geogrids environmentally friendly?

- Geogrids can be considered environmentally friendly as they are typically made from recycled materials and can be reused or recycled after their lifespan. Additionally, geogrids help stabilize soil, reduce erosion, and enhance drainage, leading to improved environmental conditions.

- Q: The difference between polyester glass fiber cloth and glass geogrid

- Hello, this is two different products

- Q: What are the procedures for using two-way geogrid

- 1 bidirectional geogrid is used to increase the bearing capacity of the road (ground) foundation, and the service life of the Yan Changlu (ground) foundation.2 bidirectional geogrid used to prevent road (ground) surface collapse or crack, keep the ground beautiful and tidy.3 bidirectional geogrid for the construction of convenient, time-saving, labor-saving, shorten the construction period, reduce maintenance costs.

- Q: What are the factors that affect the quality of glass fiber reinforced plastic grid

- FRP grating is a kind of material in recent years is more popular, this is a kind of grid plate after special processing, except for the corrosive environment, it is widely used in city greening, landscape decoration and so on, is the most common in the city green, so as a kind of glass steel products, what are the factors affecting the quality of FRP grid cover?

- Q: Is the test items within the inspection listAcceptance specification

- Stagger distance. About these items

- Q: And specification.. Thank you for answering me

- It is estimated that which is the boring manufacturers to use basalt fiber grille

- Q: Are geogrids suitable for use in high-traffic areas?

- Yes, geogrids are suitable for use in high-traffic areas. Geogrids are specifically designed to provide reinforcement and stability to soils and aggregate materials. They are capable of distributing load forces and reducing deformation, making them ideal for high-traffic areas such as roadways, parking lots, and industrial yards. Geogrids enhance the durability and lifespan of these surfaces, ensuring they can withstand heavy traffic loads without significant deterioration.

Send your message to us

Biaxial Geogrids for Roadbed Reinforcement - Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords