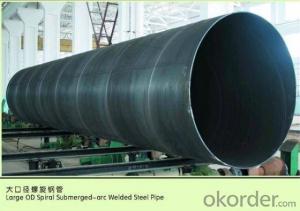

BG ssaw steel pipe with material x56 x70,large diameter sprial welded pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name | ERW Pipe / Welded Pipe / Black Pipe/LSAW | |

Size | OD | 406-1522.4mm(16-56in) |

Thinkness | 8-50mm(apply to simple carbon steel,low carbon alloy steel);6.4-26.4mm(apply to X70 and above) | |

Length | 3-12.5m or as required | |

Steel Material | Gr.B,X42-X70 PSL1, X42-X80 PSL2, L245-L555NB,A516Gr, 55-70 CL11-32 | |

Standard | APISpec5L, APISpec2B, ISO383, GB/T9711-2001,ASTMA671,ASTMA672,JIS DIN, | |

Usage | Natural gas, petroleum, chemical industry, electric power, metallurgy thermodynamic fields, water supply engineering, steam heating, hydroelectric power station and long pipeline transportation projects and so on. | |

Ends | Usually Plain ,But Can Be Beveled Or By Your Choice | |

Technique | LSAW | |

Surface | Bared Or Black Painted, Galvanized Or With Oiled Or as Client Required | |

Type | Welded | |

Section Shape | Round | |

Third Party Inspection | SGS,BV,CE | |

Inspection | 100% ultrasonic flaw detection for the material plate;100% automatic on-line UT test after welding; 100% whole-length seam X-ray test; 100% inside weld line industrial TV test; 100% hydrostatic test; 100% automatic on-line seam UT test after hydrostatic test, expanding; 100% X-ray test and make X-ray film or picture record on pipe ends; 100% pipe appearance and plate appearance inspection. | |

Package | In square bundles with standard seaworthy export packing or as request | |

Date of Delivery | 5-45days according to the QTY | |

Supply Ability | 150000tons/year | |

Port of Shipment | Tianjin Port | |

Payment term | T/T, Irrevocable L/C at sight | |

Trade Term | FOB CFR CIF | |

Others | 1) Contract Manufacturing: OEM Service Offered, Design Service Offered, Buyer Label Offered 2) Small quantity can be acceptable 3) Non-standard products can be ordered 4) A strong production capacity and a large inventory guarantee the quick delivery | |

- Q: How are steel pipes recycled at the end of their life cycle?

- Steel pipes are typically recycled at the end of their life cycle through a process called steel recycling. This involves collecting the used pipes, separating them from other materials, and then melting them down to be formed into new steel products. The recycling process not only helps conserve valuable resources but also reduces the need for new steel production, making it an environmentally sustainable solution.

- Q: How are steel pipes used in the manufacturing of pressure vessels?

- Steel pipes are commonly used in the manufacturing of pressure vessels due to their high strength and ability to withstand high pressure. These pipes are utilized as the primary material for constructing the shell of the pressure vessel, providing a robust and reliable structure. Additionally, steel pipes offer excellent resistance to corrosion, making them suitable for various industries and applications where pressure vessels are required, such as oil and gas, chemical processing, and power generation.

- Q: What are the different types of pipe coatings used for corrosion protection?

- There are several different types of pipe coatings used for corrosion protection. These coatings are applied to the exterior surface of pipes to prevent or delay corrosion, ensuring the longevity and integrity of the pipes. Some of the commonly used pipe coatings for corrosion protection include: 1. Fusion-Bonded Epoxy (FBE) Coatings: FBE coatings are widely used for corrosion protection due to their excellent adhesion and resistance to chemicals, moisture, and abrasion. These coatings are applied by heating the pipe and spraying it with epoxy powder, which then melts and forms a protective layer upon cooling. 2. Polyethylene (PE) Coatings: PE coatings are known for their flexibility and resistance to impact and chemicals. These coatings are typically applied by extrusion or wrapping methods and provide excellent resistance against water, soil, and other corrosive substances. 3. Polyurethane (PU) Coatings: PU coatings offer good resistance to chemicals, moisture, and mechanical damage. They are commonly used for underground pipelines and are applied by spraying or brush coating methods. 4. Coal-Tar Enamel Coatings: Coal-tar enamel coatings are suitable for protecting pipes exposed to highly corrosive environments such as marine conditions or underground applications. They are typically applied by hot or cold wrapping methods and provide excellent resistance to water, acids, and alkalis. 5. Metallic Coatings: Metallic coatings such as zinc, aluminum, or zinc-aluminum alloys are often used as sacrificial coatings to protect the underlying steel pipes. These coatings corrode preferentially, sacrificing themselves to protect the pipe from corrosion. 6. Asphalt Coatings: Asphalt coatings provide a robust barrier against moisture, chemicals, and soil. They are typically applied by hot or cold wrapping methods and are commonly used for underground pipelines. It is important to consider factors such as the specific environment, temperature, and expected lifespan of the pipes when selecting the appropriate type of pipe coating for corrosion protection.

- Q: How are steel pipes used in plumbing?

- Steel pipes are commonly used in plumbing for various applications such as water supply and drainage systems. They provide durability, strength, and resistance to corrosion, making them suitable for both residential and industrial plumbing. Steel pipes can be used for transporting water, gases, and other fluids, and are often connected with fittings and valves to create a reliable and efficient plumbing system.

- Q: How are steel pipes used in the oil and gas pipeline transportation?

- Steel pipes are widely used in the oil and gas industry for pipeline transportation due to their durability, strength, and resistance to corrosion. These pipes are specifically designed to withstand high pressure and transport various types of fluids, including crude oil, natural gas, and refined petroleum products. In oil and gas pipeline transportation, steel pipes are primarily used for three main purposes: gathering, transmission, and distribution. Gathering pipelines are responsible for collecting oil and gas from the production wells and transporting them to processing facilities. Steel pipes are used in these pipelines due to their ability to withstand the harsh conditions of the extraction sites and effectively transport the fluids over long distances. Transmission pipelines are used to transport oil and gas over vast distances, sometimes spanning across countries or continents. Steel pipes are ideal for this purpose as they can handle high pressure, ensuring the efficient flow of fluids over long distances. These pipes are often buried underground or submerged in water to protect them from external elements and minimize the risk of damage. Distribution pipelines are responsible for delivering oil and gas to end-users, such as homes, businesses, and industrial facilities. Steel pipes are commonly used in these pipelines as they can handle the varying demand and pressure requirements of different consumers. These pipes are often smaller in diameter compared to transmission pipelines but still provide reliable and safe transportation of oil and gas to their final destinations. In addition to their strength and durability, steel pipes used in oil and gas pipeline transportation are also coated or lined with various materials to enhance their resistance to corrosion and minimize the risk of leaks. These protective coatings and linings ensure the longevity of the pipes and maintain the integrity of the transported fluids. Overall, steel pipes play a crucial role in the oil and gas industry by providing a reliable and efficient means of transporting oil and gas from production sites to processing facilities and ultimately to end-users. Their durability, strength, and resistance to corrosion make them an ideal choice for pipeline transportation in this industry.

- Q: What is the difference between API 5L and ASTM A106 steel pipes?

- API 5L and ASTM A106 steel pipes are both widely used in the oil and gas industry, but they have some key differences. API 5L is a specification for seamless and welded steel pipes used for pipeline transportation systems in the petroleum and natural gas industries. It covers various grades of carbon and alloy steel pipes, with different strength levels and impact requirements. API 5L pipes are designed for conveying fluids, such as oil, gas, and water, over long distances. On the other hand, ASTM A106 is a specification for seamless carbon steel pipes used for high-temperature service. It covers seamless pipes for pressure and mechanical applications, including transportation of fluids and gases in industries like refineries, power plants, and boilers. While both API 5L and ASTM A106 pipes are used in similar applications, the main difference lies in their intended use and the specific requirements they must meet. API 5L pipes are primarily used for pipeline transportation systems, whereas ASTM A106 pipes are more focused on high-temperature service applications. Additionally, the manufacturing processes and testing requirements for both specifications may vary.

- Q: What are the common methods for cleaning the inner surface of steel pipes?

- There are several common methods for cleaning the inner surface of steel pipes. Some of the most widely used methods include: 1. Mechanical Cleaning: This method involves the use of mechanical tools such as wire brushes, scrapers, or abrasive pads to physically remove debris, rust, or scale from the inner surface of the steel pipe. This method is effective for removing loose or loosely adhered contaminants. 2. Chemical Cleaning: Chemical cleaning involves the use of acidic or alkaline solutions to dissolve or loosen stubborn deposits, rust, or scale on the inner surface of steel pipes. The solution is usually circulated through the pipe for a specific period of time, allowing the chemical to react and break down the contaminants. This method is often used when mechanical cleaning is not sufficient. 3. High-Pressure Water Jetting: In this method, high-pressure water is directed through a nozzle into the steel pipe, effectively removing debris, rust, or scale from the inner surface. The force of the water jet helps dislodge and flush out the contaminants. This method is particularly efficient for cleaning pipes with complex geometries or hard-to-reach areas. 4. Shot Blasting: Shot blasting involves the use of high-speed abrasive particles propelled against the inner surface of the steel pipe to remove rust, scale, or other contaminants. This method is commonly used for larger pipes or pipes with heavy deposits. It provides a thorough and uniform cleaning by removing the surface layer of the steel along with the contaminants. 5. Ultrasonic Cleaning: Ultrasonic cleaning uses high-frequency sound waves to create microscopic bubbles in a cleaning solution. These bubbles implode upon contact with the inner surface of the steel pipe, effectively loosening and removing contaminants. This method is particularly effective for cleaning small-diameter pipes or pipes with intricate details. It is important to note that the selection of the cleaning method depends on various factors such as the type and extent of contamination, pipe size and geometry, and the desired level of cleanliness. Additionally, proper safety measures should always be taken when performing any cleaning method to ensure the protection of workers and the integrity of the steel pipes.

- Q: How are steel pipes protected against rust and corrosion?

- Steel pipes are protected against rust and corrosion through various methods such as applying protective coatings, galvanizing, and cathodic protection. These measures create a barrier between the steel surface and moisture or corrosive substances, ensuring the longevity and integrity of the pipes.

- Q: How are steel pipes used in automotive manufacturing?

- Automotive manufacturing extensively employs steel pipes for a multitude of purposes. The exhaust system represents one of the principal functions of steel pipes in this industry. In vehicles, the exhaust system is accountable for securely eliminating harmful gases generated during the combustion process. Steel pipes are employed in fabricating the exhaust manifold, which collects exhaust gases from the engine cylinders and directs them towards the exhaust pipe. Additionally, steel pipes are also utilized in constructing the chassis and frame of vehicles. The chassis offers structural support and aids in upholding the overall strength and stability of the vehicle. Due to their exceptional strength and durability, steel pipes are the optimal choice for manufacturing the chassis and frame. These pipes are frequently welded together to form a rigid and robust structure capable of withstanding diverse forces and impacts. Furthermore, steel pipes find application in the suspension system of automobiles. The suspension system is responsible for delivering a comfortable and smooth ride by absorbing shocks and vibrations. Steel pipes are employed in manufacturing suspension components such as control arms, tie rods, and sway bars. These components contribute to maintaining the stability, handling, and overall performance of the vehicle. Moreover, steel pipes are utilized in the fuel system of automobiles. They are responsible for transporting fuel from the fuel tank to the engine. These pipes necessitate resistance to corrosion and possess high tensile strength to guarantee the safe and efficient delivery of fuel. In conclusion, steel pipes play a pivotal role in automotive manufacturing. They are utilized in diverse applications including the exhaust system, chassis and frame construction, suspension system, and fuel system. The incorporation of steel pipes in these areas ensures the durability, strength, and performance of vehicles while simultaneously upholding safety and efficiency.

- Q: How are steel pipes connected in pipeline construction?

- Steel pipes are connected in pipeline construction through various methods, such as welding, threading, and flanges. Welding involves melting the ends of two pipes together to form a strong and permanent bond. Threading involves cutting grooves into the ends of pipes, which are then screwed together using threaded fittings. Flanges are used to connect pipes by bolting them together, creating a secure and leak-proof connection. These connection methods ensure the integrity and durability of the pipeline system.

Send your message to us

BG ssaw steel pipe with material x56 x70,large diameter sprial welded pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords