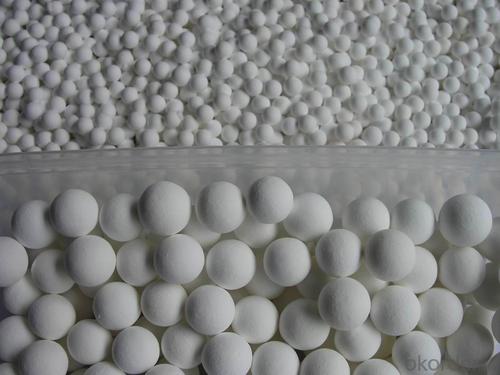

BEST QUALITY! CERAMIC BALL WITH LOW PRICE FROM CHINA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Name Items | OK70 | OK80 | OK90 | OK93 | OK95 |

Specific Gravity g/cm3 | 2.95~3.02 | 3.33~3.36 | 3.55~3.60 | 3.63~3.68 | 3.70~3.75 |

(Mohs Scale)Hardness | 8.5 | 8.5 | 9 | 9 | 9 |

Compression Strength MPa | ≥1700 | ≥1800 | ≥1850 | ≥2000 | ≥2250 |

Color | yellowish | White | White | White | White

|

Equivalent Wear Loss | ≤0.18‰ | ≤0.14‰ | ≤0.10‰ | ≤0.08‰ |

≤0.05‰ |

Standard Size

Type Size Variation Size | OK70 | OK80 | OK90 | OK93 | OK95 |

φ30mm----φ40mm | +1.8mm | +1.8mm | +1.8mm | +1.8mm | +1.8mm |

φ50mm-----φ60 mm | +2.0mm | +2.0mm | +2.0mm | +2.0mm | +2.0mm |

φ70mm-----φ80mm | +3.0 mm | +3.0 mm | +3.0 mm | +3.0 mm | +3.0 mm |

Remark: Other sizes are available upon requests.

- Q: The casting defects of pores, trachoma how to repair?

- If the repair after the high temperature resistance, choose LT737 high temperature repair agent.

- Q: Domestic large steel castings factory which is better, recommend!

- Do the casting manufacturer of large steel castings, Hunan Jinsha heavy industry science and technology limited company, heard that their professional only more than 1 tons of steel castings, anyway, 150T just big, the company won a lot of foundry industry patents should be good.

- Q: What are the effects of stiffeners on castings, or on welded parts (for 2 tons or less), casting or weldments on stiffeners?

- 4, the performance requirements of the steel: whether castings or welding parts, there may be quality defects, but the casting will generally be worse than the weldment.You should be able to make a choice in the end.

- Q: Why do cheap cars like stamping parts instead of casting parts?

- The difference between automobile stamping parts and castingsAs the saying goes, there will be progress in comparison. In fact, through comparison, we can find the advantages and disadvantages of both. Next, we will talk about the difference between car stamping parts and castings.Looking for national casting orders, ductile iron castings, purchasing castings, foundry orders, and consulting foundry technology issuesCasting order networkAutomotive stamping parts are widely used in every field of our life, including some electronic components, auto parts, decorative materials and so on.

- Q: The casting sand is going on

- 3, prevention measures(1) to improve the strength of sand mold (core), especially surface strength, high temperature strength, refractoriness, compact, better coating, good core coating and parting surface coating.(2) mould and box can prevent damage;(3) the core should have clearance.

- Q: What is the difference between forging parts and casting parts?

- The forging can guarantee the continuity of the metal fiber tissue, make the fiber structure of the forging keep the same shape as the forging, the metal streamline is complete, the tissue is compact, and the mechanical property is good. To ensure that the object has good mechanical properties and long service life, the processing of objects sharp, durable, high strength, first-class quality.

- Q: Casting parts have poor surface finish. What sand is used to make them?

- Now resin sand, coated sand and other processes are also very good surface.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- A: in the design of metal castings in a complex shape, if the production process is very difficult, should not affect the casting conditions, try to make the casting has simple shape, strong structure change, removed from metallic die for.

Send your message to us

BEST QUALITY! CERAMIC BALL WITH LOW PRICE FROM CHINA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords