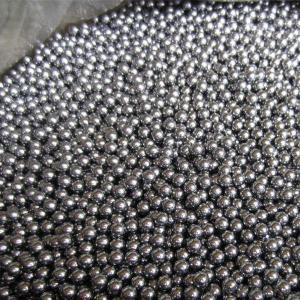

BEST QUALITY! CARBON STEEL BALL FROM CHINA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

carbon steel ball

1) G10-G1000

3) HRC55-65

4)SGS

5)tolerance:+/-0.01mm

(AISI 1010 / 1015 / 1045 / 1084 / 1085 ) carbon steel ball for bicycles

Name of the product | Carbon steel ball |

Material | AISI1010/1015/1045/1085 carbon steel. |

Diameter | 0.5 - 100mm |

Grade | G10 - G1000 |

Hardness | HRC55 - 58 |

Applications | 1. General industry for automobile, motorcycle, bicycle manufacturing, special bearings & micro – ball for the electronics industry.. 2. High accuracy & low noise motor bearing& household appliance bearings |

Packing | Medal Drum/Export Bag/Cartonor according to customers' requirements |

MOQ | 1000 pcs |

Payment | T/T , L/C , D/P , western union |

Delivery time | 10 - 15 days after receiving the advance payment |

Physical Properties

1010 (C10) | |

C | 0.08%--0.10% |

Si | --- |

Mn | 0.30%--0.6% |

P | 0.040% max. |

S | 0.050% max. |

1015 (C15) | |

C | 0.13%--0.18% |

Si | --- |

Mn | 0.30%--0.6% |

P | 0.040% max. |

S | 0.050% max. |

1045 (S45C) | |

C | 0.42%--0.48% |

Si | 0.15%--0.35% |

Mn | 0.60%--0.90% |

P | 0.030% max. |

S | 0.035% max. |

1085 (C85) | |

C | 0.80%--0.90% |

Si | 0.35%--0.45% |

Mn | 0.60%--0.90% |

P | 0.050% max. |

S | 0.050% max. |

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- Usually after rusting,Did you peel it?If it isNeed to do film processingIf notPlease look for the coating factoryBetter paint (such as epoxy ester, etc.)

- Q: Domestic large steel castings factory which is better, recommend!

- Do the casting manufacturer of large steel castings, Hunan Jinsha heavy industry science and technology limited company, heard that their professional only more than 1 tons of steel castings, anyway, 150T just big, the company won a lot of foundry industry patents should be good. At least spend money on research and development, then the quality should be all right.

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: The casting sand is going on

- Dispersed sand inclusion is common on the surface and subcutaneous of steel castings, often concentrated on the outer surface of the upper box and the inner surface of the lower case, and a few of them are inside the cast steel parts.

- Q: What method of casting does not rust? I think the sample is like oil

- The surface of a general casting is easy to rust. In order to prolong the rusting period, antirust paint or antirust oil is usually sprayed. What you said should be anti rust oil.

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- Vacuum casting is the process of using ventilation molds. Molten metal flows into the mold by air pressure, and then removes air to form a vacuum. The casting process is mainly used for small parts or jewelry with exquisite detailsCompared with the traditional clay sand casting, heat hardening resin sand casting production with low surface roughness, high precision, good quality characteristics, dimensional accuracy of resin sand mold after hardening with good rigidity and high, and not easy to deform, so in the choice of process parameters, mechanical processing you can select a smaller margin, thereby reducing the consumption of metal solution and machining cost, which can improve the dimensional accuracy of castings.

- Q: How can the casting be quenched and tempered?

- Another is the result of pre heat treatment (quenching or annealing) after quenching and tempering treatment, suitable for ZG35SiMNMo, ZG35CrMo and so on. Please tell the casting process is your product and material and then set tempered.: shutup:

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: Why do casting parts have air holes?

- There are many reasons for casting porosity, mainly due to:1. smelting process is unreasonable, metal liquid absorbs more gas;2. the gas in the mold invades the metal liquid;3. from the mold is more water brush, core dry;4. the casting has poor ventilation;5. ladle tools are not dry.Wait。

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

Send your message to us

BEST QUALITY! CARBON STEEL BALL FROM CHINA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords