Best Price High Quality 0.5W 5730 SMD LED

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

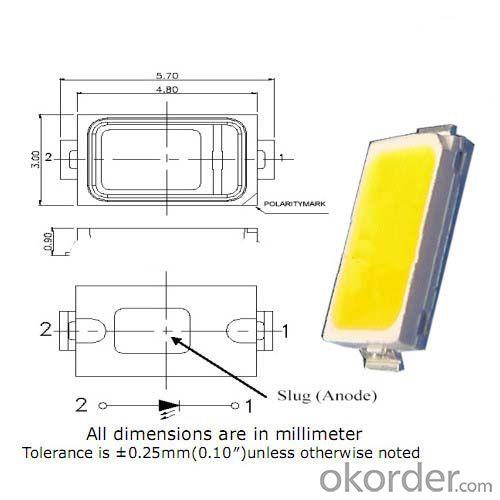

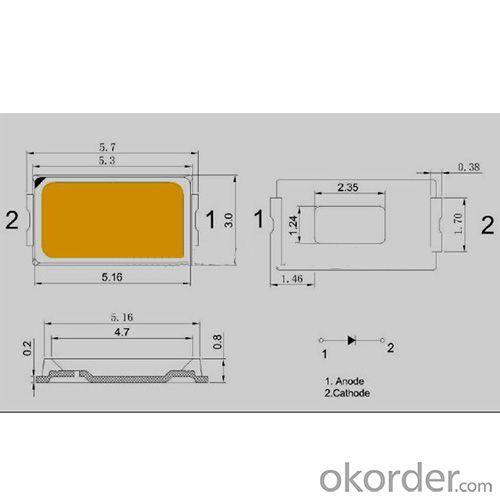

Technical Date Sheet:0.5W 5730 SMD

| Name | 5730 smd led |

| Lumens | 50-55lm |

| Forward Current | 150mA |

| Forward Voltage | 3.0~3.6v |

| Color Temperature | 2800-3300K,6000-6500K |

| Viewing Angle | 120° |

| Operation Temperature | -25~+80 °c |

| Storage Temperature | -40~+80 °c |

| Lifespan | 50.000hours |

| Certification | RoHS |

ABSOLUTE MAXIMUM RATING (Ta=25°C) 0.2W SMD Datasheet

Item | Symbol | Value | Unit |

Peak Forward Current | IFp | 150 | mA |

Reverse Voltage | VR | 5.0 | V |

Continuous Forward Current | IF | 150 | mA |

Recommend Operating Current | IF | 18 | mA |

Operating Temperature | Topr | -40 to 85 | °C |

Storage Temperature | Tstg | -40 to 100 | °C |

Lead Soldering Temperature | Tsol | 260°C for 3 seconds | |

CHARACTERISTICS(Ta=25°C)

Parameter | Condition | Symbol | Min | Typ | Max | Units |

Power Dissipation | IF=150mA | Pd | / | 60 | / | mw |

Correlated Color Temperature | IF=150mA | CCT | 6000 | / | 10000 | K |

Forward Voltage | IF=150mA | VF | 2.8 | 3.2 | 3.8 | V |

Reverse Current | VR=5V | IR | / | / | 10 | μA |

Chromaticity Coordinates | IF=150mA | X | / | 0.31 | / |

|

IF=150mA | Y | / | 0.33 | / |

| |

Luminous Flux | IF=150mA | ΦV | 45 | 50 | 55 | LM |

Luminous Intensity | IF=150mA | IV | / | mcd | ||

Color Rending index | IF=150mA | CRI | / | 70 | / | Ra |

Full Viewing Angle | IF=150mA | 2Φ1/2 | / | 120 | / | deg |

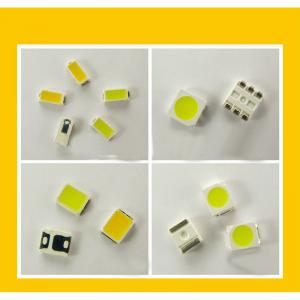

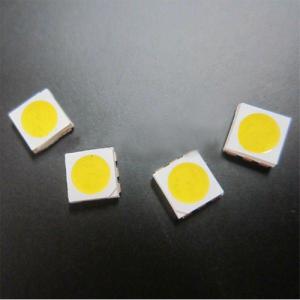

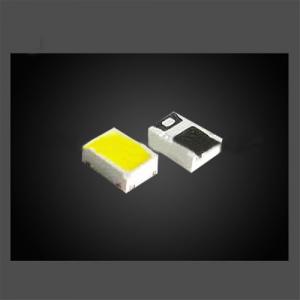

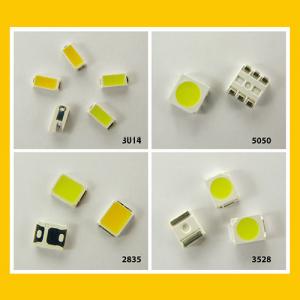

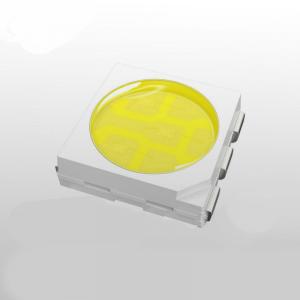

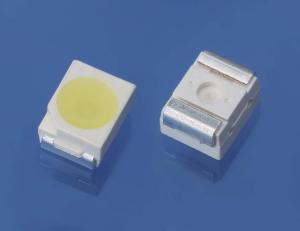

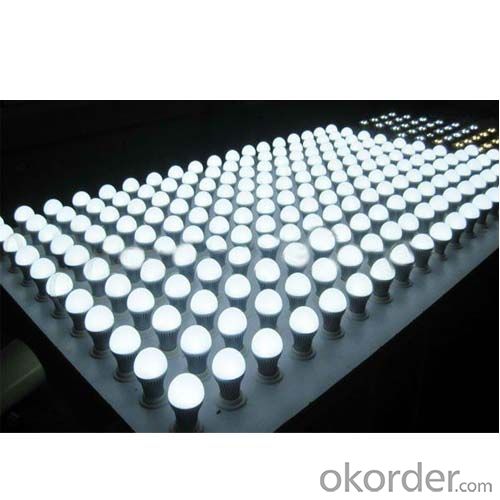

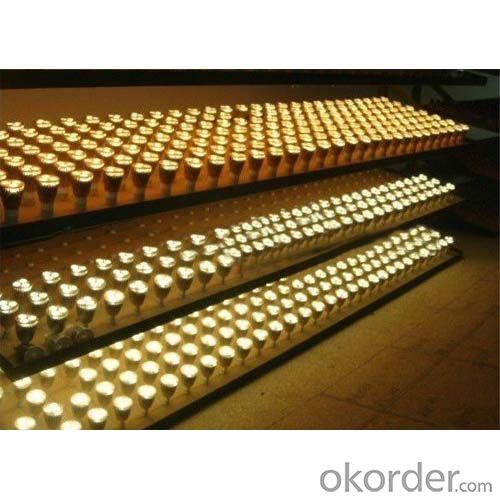

Pruoduct Show:

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

Air freight | 3-10 business days |

By Sea | 30-40 business days |

1. 3-5 business days for Sample Orders; 7-30 business days for Bulk Orders for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: What determines the brightness of the patch LED?

- The current through the lamp itself. If the same lamp, so it is necessary to ensure consistency in the different current circuit, the test voltage of little significance, especially in the case of parallel lamp, current a few beads each share is not the same, some big, some small.

- Q: What is the principle used in SMD LED lamp, should pay attention to what the problem?

- LED white is the light emitting diode, a PN junction to the most important use of SMD beads is the heat, according to the different manufacturer beads, glue package is not the same, should pay attention to pre baking time and temperature, the latter should pay attention to the patch temperature, the most important is the price, many manufacturers in order to cost savings, internal chip used is too small does not meet the standards, support steal frugal material, with iron, the failure cycle shortened, LED lamp can not reach the ideal effect. Again, the LED supply current must not exceed the rated value, which is an important factor in damage to lamps and lanterns

- Q: Indoor full color LED display module and LED what is the difference between a full color?

- Indoor full color LED display module and LED chip has three full color difference. The first part: Second: third light emitting display module: maintenance: LED full color display is not easy to maintain. LED full color patch is relatively easy to maintain.

- Q: What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- The power of the soldering iron should not be too big. Generally choose 20--35 watt welding time as short as possible, it is best to hang the copper wire on the solder, do not use solder paste in the soldering flux, and choose the rosin as well

- Q: What is the difference between patch LED beads and LED beads: General

- A pin of the lamp, and outside a resin cap, because the reason LED beads can spotlight cap;There is no pin on the patch and there is no resin cap outside. Because of the lack of cap, the LED patch can not be concentrated.Patch is based on small power, the shape is relatively small (usually 0.5 and 0.5W products)It's called patch because some small ones need Mounter to machine.The ordinary LED lamp, solder joints than SMD beads, now is the largest artificial welding. Regular watts count from 1-300W

- Q: Patch LED features

- Without heating time, lighting is faster than general light (about 3 ~ 400ns).The electro optic conversion efficiency is high, the power consumption is small, and the energy consumption is about 1/3 ~ 1/20 than that of the bulb.

- Q: Notes on patch LED

- Clean, do not use an unknown chemical liquid to clean the patch LED: an unknown chemical liquid may damage the patch LED. When necessary, immerse the patch LED in alcohol, less than 1 minutes at normal room temperature, and dry naturally for 15 minutes before starting to use

- Q: LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- Mold release agent is a functional substance between the mold and the finished product. The release agent is chemically resistant and is not soluble in contact with the chemical constituents of different resins (especially styrene and amines). Release agent also has heat and stress properties, not easy to decompose or wear; release agent bonded to the mold, and not transferred to the processed parts, without prejudice to painting or other two processing operations. Because of the rapid development of injection molding, extrusion, calendering, molding and laminating, the dosage of mould release agent is greatly improved.

- Q: The ten patch LED lights are connected in parallel. The rated power is 5 watts. How much voltage do you need?

- The voltage needs to be determined according to the product specification, usually 3.1 - 3.5V

- Q: How do led patches measure good or bad?

- Use the two stage tube test of the multimeter, the red pen is connected, and the black pen is negative. If there is a bee, the sound is bad, and if the light is bright, it is good

Send your message to us

Best Price High Quality 0.5W 5730 SMD LED

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords