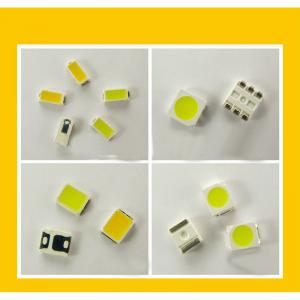

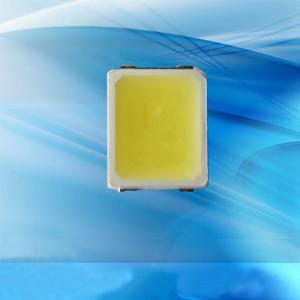

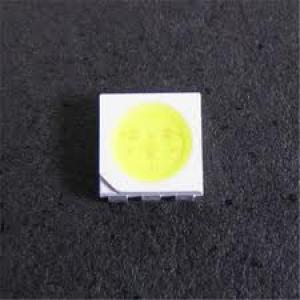

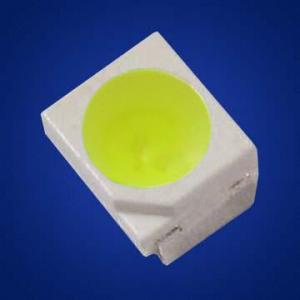

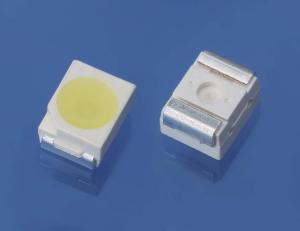

2835 60mah 0.2W LED-2835 SMD LED

- Loading Port:

- Taibei

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

All-Brite AE2835S-02LEXX package has high efficacy, low power consumption, wide viewing angle and a compact form factor.

These features make this package an ideal LED for all lighting applications.

Features

PLCC-2 package |

Top view white LED |

High luminous intensity output |

Wide viewing angle |

Pb-free |

RoHS compliant |

Applications

General lighting |

Decorative and Entertainment Lighting |

Indicators |

Illumination |

Switch lights |

Absolute Maximum Ratings (TSoldering=25°C)

| Parameter | Symbol | Rating | Unit |

Forward Current | IF | 75 | mA |

Peak Forward Current (Duty 1/10 @10ms) | IFP | 100 | mA |

Power Dissipation | Pd | 270 | mW |

Operating Temperature | Topr | -40 ~ +85 | °C |

Storage Temperature | Tstg | -40 ~ +100 | °C |

Thermal Resistance (Junction / Soldering point) | Rth J-S | 50 | °C/W |

Junction Temperature | T j | 125 | °C |

Soldering Temperature | Tsol | ||

Packaging & Shipping

Packing:

Standard packing inside, cartons outside

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

Air freight | 3-10 business days |

By Sea | 30-40 business days |

1. 3-5 business days for Sample Orders; 7-30 business days for Bulk Orders for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: What determines the brightness of the patch LED?

- The brightness is consistent over a short period of time, that is, only by considering current and voltage consistency.Long term brightness is consistent with the consideration of the spacing and heat dissipation of different circuits. Uneven heat can also affect brightness.

- Q: Indoor full color LED display module and LED what is the difference between a full color?

- Indoor full color LED display module and LED chip has three full color difference. The first part: Second: third light emitting display module: maintenance: LED full color display is not easy to maintain. LED full color patch is relatively easy to maintain.

- Q: What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- It is best to use a hot-air gun heat transfer high air volume adjustable low moment welding, the specific heat jump to the appropriate place to see what you use what kind of welding wire, welding wire of different because of the different melting point impurities also some differences. The air volume is too high, easy to blow the original

- Q: How does the LED placement lamp distinguish the positive and negative poles? There is no sign on the light. Thank you

- You can also use the ohmmeter's ohmmeter. To dial multimeter, to "ohm X1" file, the light emitting diode when the red pen is connected to the positive terminal of SMD LED, the black probe is connected to the negative terminal of SMD LED.

- Q: What is patch SMD-LED?

- Semiconductor wafers consist of two parts, one is P type semiconductor, in which the hole dominates, and the other end is N type semiconductor, which is mainly electronic here. But when the two semiconductors are connected, they form a P-N junction between them. When the current passes through the wire acting on the chip, the electrons are pushed into the P region. In the P region, electrons combine with the hole and then emit energy in the form of photons, which is the principle of LED luminescence. The wavelength of light, that is, the color of light, is determined by the material that forms the P-N junction.

- Q: Patch LED light does not flash, why?

- Are you saying that lamp is flashing? You can check the power output, according to your standard parameters and SMD beads, lamp panel series parallel mode, calculate the power output to output power of the test, you may be wrong, power, overload, but also the effective part of you may be the circuit for power transmission is not stable or low

- Q: What are the storage requirements of SMT patch LED (LED)?

- Moisture-proof packing- anti SMD LED in the transport and storage of moisture absorption, SMD LED shall be placed in sealed moisture-proof bag, inside put damp proof agent for protection, and placed the humidity humidity SMD display card packaging bag.

- Q: Patch LED features

- The seismic resistance, high reliability, low operation cost system.It is easy to small, thin, lightweight, easy to shape without restrictions, made all kinds of application.

- Q: The quality of the LED patch module

- Chip manufacturers, the top chip mainly from the United States, Germany, Japan and South Korea and so on. But on the mainland LED module manufacturers to use the vast majority of chip from Taiwan, of course, there are a lot of use of chip, market positioning, the main users of the product features with the manufacturers and government policies, different chip manufacturers are different its stable performance. Maybe you will ask why not CREE, OSRAM, Nichia, first of the world's top chip manufacturers have fixed target market positioning, such as defense orders, and said, specially import a little CREE chip manufacturing module, it is also not cost-effective; and if the driver is not supporting the raw materials, it can not be completely play the advantage, so is also a great waste.

- Q: Patch LED light broken one, short circuit can use it?

- Can not casually short-circuit, according to the LED connection, but also to see the power supply voltage and current, all the LED can not flow. Any short circuit may cause excess LED to flow over or over, causing a chain reaction, a bad string,...... .

Send your message to us

2835 60mah 0.2W LED-2835 SMD LED

- Loading Port:

- Taibei

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords