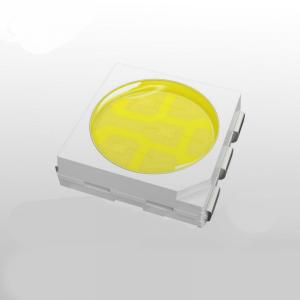

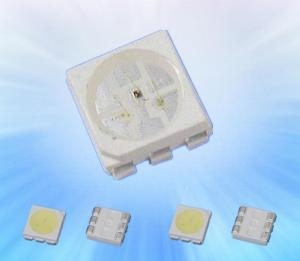

5730 SMD Led, 0.5W 5730 SMD Led, 60 Lm 5730 SMD Led

- Loading Port:

- Shanghai

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 3000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

5730 smd led features

Our Products Stand out of Others

Over 12 years producing experience as the vendor of Samsung,Haier,LG etc.

Big scale of producing makes sure that your purchase cost is lower.

Advanced production line guarantees stable quality and long life span.

ELECTRICAL/OPTICAL CHARACTERISTICS AT Ta=25°C:

PARAMETER | SYMBOL | TEST CONDITION | Color | MIN | TYP | MAX | UNIT |

Forward Voltage | VF | IF=150mA | White |

3.0

| 3.2 | 3.6 | V |

Reverse Current | IR | VR=5V | White |

|

| 50 | μA |

Peak Emission Wavelength | CT | IF=150mA | White | 6000 | ----- | 6500 | K |

Luminous Intensity | IV | IF=150mA | White | 50 | --- | 60 | LM |

Payment term:

100% TT in advance. Order quantity more than 10,000,000pcs, 30% T/T deposit, balance against B/L copy, L/C

Caution:

1. The power and socket must be safe and standard for service the life of battery.

2. Please do not use when charging, in case burn LED bulbs and damage inner components.

3. Pleased do not shot the eyes directly (Children must be instructed by adults).

4. Keep away form rain and wet.

5. Keep far away from the exploders when charging ,the charging time could not be more than 24 hours.(Suggestion charging in daylight time)

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By Sea | 30-40 business days |

1. 3-5 business days for Sample Orders; 7-15 business days for Bulk Orders for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: Production of a number of substrates, the use of SMD LED lights, red lights and green lights are not bad, blue lights appear mass dark, do not know why? Is the LED blue light material easy to use dark?

- The pressure drop of the blue light is greater than that of the red light and the green light. If the series connection is the same as that of the green light and red light, the current limiting resistor will tend to dim

- Q: Indoor full color LED display module and LED what is the difference between a full color?

- (1): LED full color light emitting module display module is generally yellow green, pure green module price is more expensive; SMD full color LED display using pure green tube coreThe display module (2): LED full color pixel visual feeling is thick, low brightness, easy to have the mosaic phenomenon; patch LED full color consistent, high brightness;(3): maintenance module LED full color display is not easy to maintain, the whole module replacement cost is high; SMD full-color LED screen for easy maintenance, repair and replacement of single lamp;

- Q: What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- I recommend reflow soldering under normal conditions and manual welding only when repaired. 2 manual soldering electric soldering iron maximum power can not exceed 30W, welding temperature is controlled within 300 degrees, welding time less than 3 seconds. 3 do not touch the colloidal iron welding head. 4 when the pin is heated to 85 degrees centigrade or higher than this temperature, it can not be pressed. Otherwise, the welding will be broken.

- Q: LED light SMD LED package in what form, trouble you under the guidance of...

- There are 3 types of LED packages: inline LED, piranha LED, and surface mount LED

- Q: Is the forward voltage drop of the patch LED too large or too small?

- The pressure drop in the normal range is generally better. The smaller the pressure drop, the lower the power dissipation. The more you save the electricity bill.But not to say that the smaller the better, not in the normal range of low pressure drop products may be defective.In addition, the uniformity of the LED pressure drop is also important.

- Q: Which is good for LED patch and LED bulb?

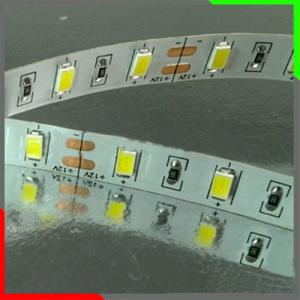

- The LED patch is the same as the LED bulbLED (light emitting diode) patch (package)The LED patch (SMD) is made of FPC circuit board, LED and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.LED bulbWith the LED patch or LED plug-in LED (light emitting diode), series or parallel, driving power supply, making a combined shell lampshade capable of converting electrical energy into visible solid semiconductor devices, which can be directly converted into electricity to light.

- Q: LED patches have several ways of welding. Which ones can be reflow? What can be done by eutectic welding? Is the welding of viscose and lens material is required?

- L electrode for eutectic solder reflow, the other can be used, regardless of the kind of welding, the temperature is not lower than 100 degrees, the flammable soluble materials have strict requirements, depending on whether the welding temperature is lower than the melting point of what you said or. Otherwise, there will be deformation or damage to the material in the reflow process.

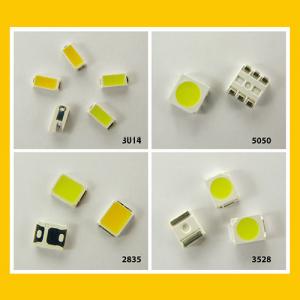

- Q: Patch LED market conditions

- Conventional monochrome SMD LED package sizes are 1206 (3215), 1004 (2510), 0805 (2012) and 0603 (1608). Chinese manufacturers can provide a minimum size of 0603, the thickness of only 0.3 mm. A smaller LED of 0402 (1005) is still in trial manufacture

- Q: The quality of the LED patch module

- Chip size. The larger the size of the same chip, the higher the general brightness, the stronger the bearing capacity, the higher the stability performance, of course, the price is relatively high. The size of the module chips now includes: 9MIL, 10MIL, 12MIL, 14MIL, 23MIL, and so on.

- Q: SMD LED lamp working voltage?

- LED is a light emitting device of low voltage, low current, low power forward current general patch type LED when using (IF) 20MA, (VF) 1.8-2.5V, voltage of red green and blue (VF) voltage is 3.0-3.6V. Different manufacturers also have small differences, so first of all, look at the color,Of course. The multi chip assembly in high voltage chip together, some current: 1 watts, 1 watts and above. A wide variety of varieties, as follows:

Send your message to us

5730 SMD Led, 0.5W 5730 SMD Led, 60 Lm 5730 SMD Led

- Loading Port:

- Shanghai

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 3000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords