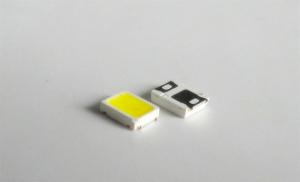

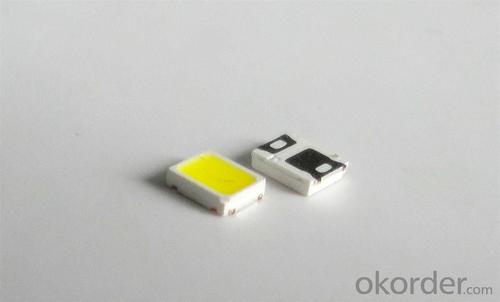

LED SMD 2835 24-26LM 2700-7500K

- Loading Port:

- Shenzhen

- Payment Terms:

- TT

- Min Order Qty:

- 5000 Pcs pc

- Supply Capability:

- 10000000 Pcs Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

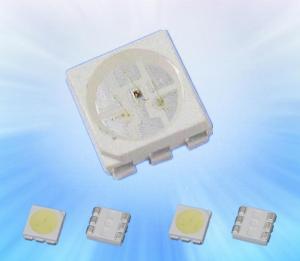

LED SMD 2835 24-26LM 2700-7500K Regular color temperature:

warm white 2600-2900K,2900-3200K,3000-3500K

natural white 4000-4500K,4500-5000K

cool white 5000-5500K,5500-6000K,6500-7000K

cold white 7000-9000K,9000-15000K

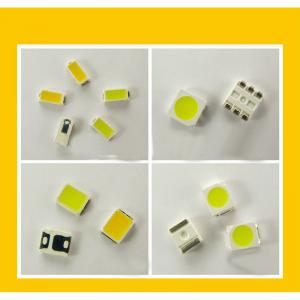

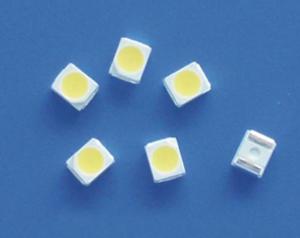

Available SMD type:

3528, 2835, 5050, 5730, 3037

Stable quality w0, 5730, 3030

Stable quality with low optical attenuation

1000h<1%, 3000h<3%, 10000h<8%

A. Meet CE, FCC, RoHS, EMC,LVD certification;

B. No RF interference, no buzzing noise and no UV radiation;

C. Low power consumption, high intensity low lumen attenuation and wide range of available operating voltage;

D. Easy to install and maintain,replacement of traditional bulbs;

E. Environment-friendly, No hazard of mercury or lead entering the environment.

F. High efficiency and energy-saving compared to conventional fluorescents which are equal bright, an

warm white 2600-2900K,2900-3200K,3000-3500K

natural white 4000-4500K,4500-5000K

cool white 5000-5500K,5500-6000K,6500-7000K

cold white 7000-9000K,9000-15000K

Available SMD type:

3528, 2835, 5050, 5730, 3037

Stable quality w0, 5730, 3030

Stable quality with low optical attenuation

1000h<1%, 3000h<3%, 10000h<8%

A. Meet CE, FCC, RoHS, EMC,LVD certification;

B. No RF interference, no buzzing noise and no UV radiation;

C. Low power consumption, high intensity low lumen attenuation and wide range of available operating voltage;

D. Easy to install and maintain,replacement of traditional bulbs;

E. Environment-friendly, No hazard of mercury or lead entering the environment.

F. High efficiency and energy-saving compared to conventional fluorescents which are equal bright, an

- Q: What is the principle used in SMD LED lamp, should pay attention to what the problem?

- LED installation method 1, don't install the LED pin in 2, under the condition of deformation in printed circuit board when installing LED, circuit board hole center distance and LED pin center spacing should be the same, if the hole spacing will make the lamp feet have residual stress and welding...

- Q: What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- Epoxy resins turn yellow during short wave irradiation or long periods of high temperature, so they are very short lived when applied to high power lighting. That's why the LED lighting market is dominated by silica gel.But because of the low price of epoxy resin (silica gel and not at a level), and storage, use and processing is superior to silica gel, so the low power LED and some optical components still use epoxy resin package.

- Q: What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- It is best to use a hot-air gun heat transfer high air volume adjustable low moment welding, the specific heat jump to the appropriate place to see what you use what kind of welding wire, welding wire of different because of the different melting point impurities also some differences. The air volume is too high, easy to blow the original

- Q: What is patch SMD-LED?

- SMD LED is the surface mount light emitting diode. It is a solid state semiconductor device that converts electricity directly into light. The heart of LED is a semiconductor wafer, one end of which is attached to a bracket, one end is negative, and the other is connected to the positive electrode of the power to encapsulate the entire wafer with epoxy resin.

- Q: How many volts is a single LED on the LED patch band?

- LED patch lamp is made of FPC circuit board, LED lamp and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.

- Q: Patch LED features

- The principle of luminescence is that of cold luminescence, not by heating or discharging light, so the component life is about 50~100 times longer than that of tungsten filament bulb, and about one hundred thousand hours.

- Q: What is patch LED?

- Patch LED refers to surface mount LED.The LED is separated from the PCB board in the form of inline and surface mount. Piranha, 3mm lights, and 5mm lights are all pins. While most high-power LED is surface mount, that is, patches. Small power LED also has the form of surface mount such as PLCC-2 and PLCC-4.

- Q: What is the difference in performance between the LED plug-in and the LED patch?

- The cooling of the plug-in is not good, because the plug-in's lamp foot, in order to save costs, generally use iron plus coating, heat conduction is not very good.The strength of aluminium alloy is not enough, it is easy to break, and copper is expensive.Relatively speaking, the patch is good, because the heat is welded on the PCB, copper or direct aluminum substrate cooling, patches near.Otherwise, why do high-power patch it?!SMT direct placement machine, a high degree of automation, low rate of bad.

- Q: What does "1210" mean in patch LED?

- At present, most manufacturers of SMD light strip used by 3528 and 5050, and 3535 and 5630 in the majority, there are many of the 3528 and 5050 and 3535, such as patch LED used in automotive lighting.

- Q: How do led patches measure good or bad?

- LED patch how to measure methods: use two meter meter test, red pen is positive, black pen negative, if there is "bee" sound is bad, if the light is good

The total area of 25,000 square meters. Company R & D, production, sales, service integration, professional development and production of high brightness - blue-white, pure purple pure green ﹑ series of high-end full-color LED (light emitting diode).

1. Manufacturer Overview

| Location | Shenzhen,China |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | Mid East;Western Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | |

| No.of Employees in Trade Department | 60 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | About 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Cheap |

Send your message to us

LED SMD 2835 24-26LM 2700-7500K

- Loading Port:

- Shenzhen

- Payment Terms:

- TT

- Min Order Qty:

- 5000 Pcs pc

- Supply Capability:

- 10000000 Pcs Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords