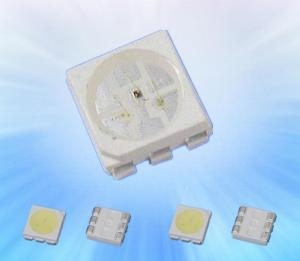

LED SMD 3014 13-15LM 2700-7500K

- Loading Port:

- Shenzhen

- Payment Terms:

- TT

- Min Order Qty:

- 5000 Pcs pc

- Supply Capability:

- 10000000 Pcs Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

LED SMD 3014 13-15LM 2700-7500K Regular color temperature:

warm white 2600-2900K,2900-3200K,3000-3500K

natural white 4000-4500K,4500-5000K

cool white 5000-5500K,5500-6000K,6500-7000K

cold white 7000-9000K,9000-15000K

Available SMD type:

3528, 2835, 5050, 5730, 3031

Stable quality w0, 5730, 3030

Stable quality with low optical attenuation

1000h<1%, 3000h<3%, 10000h<8%

A. Meet CE, FCC, RoHS, EMC,LVD certification;

B. No RF interference, no buzzing noise and no UV radiation;

C. Low power consumption, high intensity low lumen attenuation and wide range of available operating voltage;

D. Easy to install and maintain,replacement of traditional bulbs;

E. Environment-friendly, No hazard of mercury or lead entering the environment.

F. High efficiency and energy-saving compared to conventional fluorescents which are equal bright, an

warm white 2600-2900K,2900-3200K,3000-3500K

natural white 4000-4500K,4500-5000K

cool white 5000-5500K,5500-6000K,6500-7000K

cold white 7000-9000K,9000-15000K

Available SMD type:

3528, 2835, 5050, 5730, 3031

Stable quality w0, 5730, 3030

Stable quality with low optical attenuation

1000h<1%, 3000h<3%, 10000h<8%

A. Meet CE, FCC, RoHS, EMC,LVD certification;

B. No RF interference, no buzzing noise and no UV radiation;

C. Low power consumption, high intensity low lumen attenuation and wide range of available operating voltage;

D. Easy to install and maintain,replacement of traditional bulbs;

E. Environment-friendly, No hazard of mercury or lead entering the environment.

F. High efficiency and energy-saving compared to conventional fluorescents which are equal bright, an

- Q: What determines the brightness of the patch LED?

- Lamp brightness level itself, is also in the rated current situation, its brightness

- Q: What is the principle used in SMD LED lamp, should pay attention to what the problem?

- Table 1, contact electrostatic protection LED product should be covered with protective electric tape, and its reliable grounding; 2, personnel shall wear groundstrap in contact with LED (best for cable, protective gloves, anti-static ring) allows better wear anti-static clothing, anti-static shoes and static electricity cap; 3, the application in the process of exposure to LED equipment must be reliable grounding, such as iron, shearing machine, bending machine and welding equipment. Conditional still can install plasma fan to eliminate electrostatic; 4, in use or when designing electronic circuit, must consider the harm that excessive current has to LED

- Q: LED patch lamp band, how to calculate how many watts a meter, such as 3528-60 beads is how much?

- 3528-60 is 60 meters per lamp, 3528 SMD lamp with no 5050 light, about 10 watts per meter. Copper wires have less resistance and may be less than 10 watts per meter.

- Q: What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- The power of the soldering iron should not be too big. Generally choose 20--35 watt welding time as short as possible, it is best to hang the copper wire on the solder, do not use solder paste in the soldering flux, and choose the rosin as well

- Q: Led lamp and Led patch two what is the difference between ah, the feeling is a patch of long service life, whether or not? 5-10 meters pan area lighting lamp selection Everbright shaped or patch shape?

- Patches do some high-end things, large luminous area, from afar to see more clearly, 5-10 meters with patches better!

- Q: What, in what way do I shunt the LED?

- In series, the voltage is 20 times the rated voltage, in parallel, the voltage is rated voltage, but in tandem, a LED is broken, it is not bright, so it is recommended not to use it.

- Q: What is patch SMD-LED?

- This really do not know how to answer you, like a sheet of the same type of solder paste used to operate, it can be said that the plug-in is not, it is patch it!

- Q: What are the storage requirements of SMT patch LED (LED)?

- Moisture-proof packing- anti SMD LED in the transport and storage of moisture absorption, SMD LED shall be placed in sealed moisture-proof bag, inside put damp proof agent for protection, and placed the humidity humidity SMD display card packaging bag.

- Q: What is the difference in performance between the LED plug-in and the LED patch?

- The cooling of the plug-in is not good, because the plug-in's lamp foot, in order to save costs, generally use iron plus coating, heat conduction is not very good.The strength of aluminium alloy is not enough, it is easy to break, and copper is expensive.Relatively speaking, the patch is good, because the heat is welded on the PCB, copper or direct aluminum substrate cooling, patches near.Otherwise, why do high-power patch it?!SMT direct placement machine, a high degree of automation, low rate of bad.

- Q: SMD LED lamp working voltage?

- Voltage range of white LED lamp: 3.0-3.4VThe pressure drop of the red LED is 2.0--2.2VThe yellow light emitting diode has a pressure drop of 1.8 - 2.0VThe green light emitting diode has a pressure drop of 3 - 3.2VThe blue light emitting diode has a pressure drop of 3.0-3.4VSMD voltage is basically the same as double lead line. Current is generally 20~60mA, and some work current can exceed 100mA.

The total area of 25,000 square meters. Company R & D, production, sales, service integration, professional development and production of high brightness - blue-white, pure purple pure green ﹑ series of high-end full-color LED (light emitting diode).

1. Manufacturer Overview

| Location | Shenzhen,China |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | Mid East;Western Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | |

| No.of Employees in Trade Department | 60 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | About 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Cheap |

Send your message to us

LED SMD 3014 13-15LM 2700-7500K

- Loading Port:

- Shenzhen

- Payment Terms:

- TT

- Min Order Qty:

- 5000 Pcs pc

- Supply Capability:

- 10000000 Pcs Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords