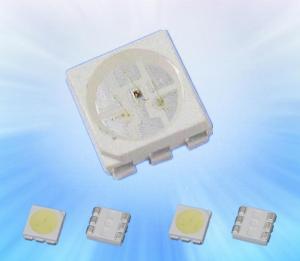

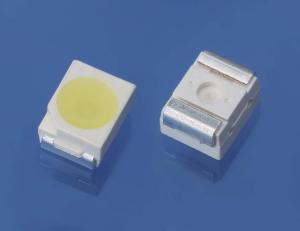

LED SMD 5050 14-16lm 6000-7000K

- Loading Port:

- Shenzhen

- Payment Terms:

- TT

- Min Order Qty:

- 5000 Pcs pc

- Supply Capability:

- 10000000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

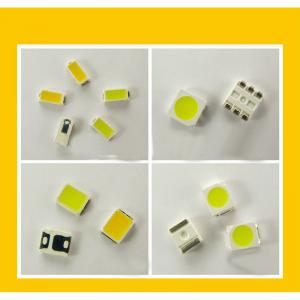

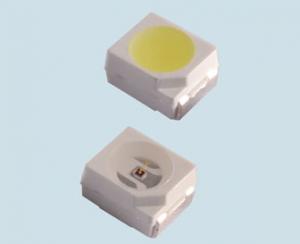

LED SMD 5050 14-16lm 6000-7000K Regular color temperature: warm white 2600-2900K,2900-3200K,3000-3500Knatural white 4000-4500K,4500-5000Kcool white 5000-5500K,5500-6000K,6500-7000Kcold white 7000-9000K,9000-15000KAvailable SMD type:3528, 2835, 5050, 5730, 3030Stable quality w0, 5730, 3030Stable quality with low optical attenuation1000h<1%, 3000h<3%, 10000h<8%A. Meet CE, FCC, RoHS, EMC,LVD certification;B. No RF interference, no buzzing noise and no UV radiation;C. Low power consumption, high intensity low lumen attenuation and wide range of available operating voltage; D. Easy to install and maintain,replacement of traditional bulbs;E. Environment-friendly, No hazard of mercury or lead entering the environment.F. High efficiency and energy-saving compared to conventional fluorescents which are equal bright, an

- Q: What is the principle used in SMD LED lamp, should pay attention to what the problem?

- LED installation method 1, don't install the LED pin in 2, under the condition of deformation in printed circuit board when installing LED, circuit board hole center distance and LED pin center spacing should be the same, if the hole spacing will make the lamp feet have residual stress and welding...

- Q: How can I install the patch LED lamp belt on the wood chip casting board? With double-sided glue will be hot, and can not use the clip on the screw, what should I do?

- With double-sided adhesive, the temperature will not be very high. So it won't fall either. That's how I got it. It took me more than half a year, and I didn't have any problems

- Q: How does the LED placement lamp distinguish the positive and negative poles? There is no sign on the light. Thank you

- Because the LED open threshold is about 1.5-1.8V. It is possible that the voltage supplied by the digital multimeter does not activate it. So look at the sign. Patch LED (SMD LED), the green point of negative, relative to the positive.

- Q: Patch LED beads can be bought in what place?

- Many LED packaging plants do patch LED, you can find the relevant manufacturers to contact, or go to the local electronic components market according to your needs

- Q: What does patch LED light mean?

- The patch may be said, adding that the patch board PCB light source, light source lamp light source generally refers to, patch may refer to the combination of PCB plate and two lens beads.

- Q: Patch LED market conditions

- With good market expectations for the future status of SMD LED, all the major manufacturers have launched their own SMD LED development planning and prototype products, all of a sudden, SMD LED market showing a flourishing and lively atmosphere of contention of a hundred schools of thought.

- Q: How many volts is a single LED on the LED patch band?

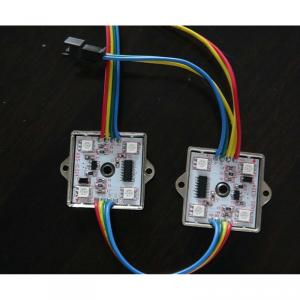

- LED patch lamp is made of FPC circuit board, LED lamp and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.

- Q: What are the storage requirements of SMT patch LED (LED)?

- Keep in storage- the original sealing bag packing in the condition of the <40 C and <90% RH degrees for 12 months, more than the storage period will bake.Please check the leak before opening the packing bagIn opening the sealed bag, should be placed in SMD LED and C 60%RH. < < 30 degrees under the conditions in the above conditions, SMD LED must be in the open package using reflow within 24 hours. If placed more than 24 hours, you need to bake- baked, SMD LED in C + 80 degrees 5 degrees C and <=10%RH relative humidity in the oven for 24 hours? remove the pouch before baking, and do not open the oven door frequently

- Q: The quality of the LED patch module

- Chip manufacturers, the top chip mainly from the United States, Germany, Japan and South Korea and so on. But on the mainland LED module manufacturers to use the vast majority of chip from Taiwan, of course, there are a lot of use of chip, market positioning, the main users of the product features with the manufacturers and government policies, different chip manufacturers are different its stable performance. Maybe you will ask why not CREE, OSRAM, Nichia, first of the world's top chip manufacturers have fixed target market positioning, such as defense orders, and said, specially import a little CREE chip manufacturing module, it is also not cost-effective; and if the driver is not supporting the raw materials, it can not be completely play the advantage, so is also a great waste.

- Q: SMD LED lamp working voltage?

- Single chip of 1 watts, more than a lot, different colors, the voltage will be different. White is usually 3.0-3.6V.* in addition to their working voltage, working current is more important parameters, once the flow, it will burn out.The LED lamp. With chips is variety, many tricks, they can be connected in series and parallel. The voltage is divided into high voltage, low voltage and medium voltage

1. Manufacturer Overview

| Location | Shenzhen,China |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | Mid East;Western Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | |

| No.of Employees in Trade Department | 60 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | About 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Cheap |

Send your message to us

LED SMD 5050 14-16lm 6000-7000K

- Loading Port:

- Shenzhen

- Payment Terms:

- TT

- Min Order Qty:

- 5000 Pcs pc

- Supply Capability:

- 10000000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords