5050 SMD LED Chip, High Quality Epistar LED Chip

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 50000 Pcs bag

- Supply Capability:

- 100000 Pcs Per Month bag/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction

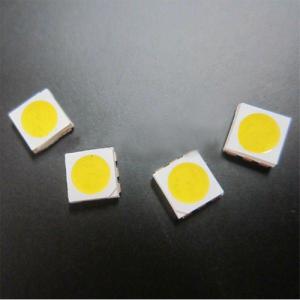

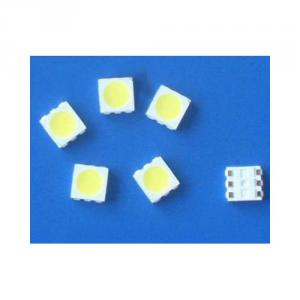

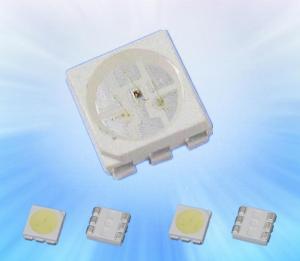

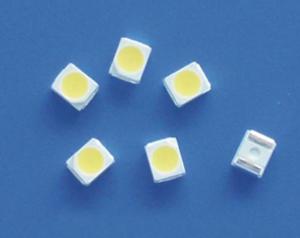

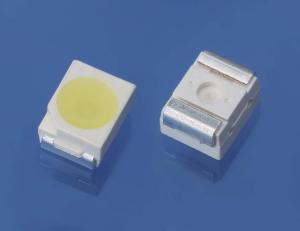

5050 SMD LED Chip,High Quality Epistar LED Chip

5.0mmx5.0mm SMD LED, 1.5mm Thickness

Specification

| Size | 5.0*5.0mm |

| Shapes | SMD |

| Emitting color | White |

| Beam Angle | 120 degree |

| C.C.T | 6,500K |

| Forward Voltage | 3.2-3.6V |

| Forward Current | 60mA |

| Lens colors | Yellow diffused |

| Life span | 50,000hours |

| Packing | 2000pcs/reel |

| Certificates | CE |

| Luminous Intensity | 5000-8000mcd |

Features and our advantages

1. Emitted Color: 5050 SMD LED white color

CCT : 3000-7000K

Luminous Flux: 15-23lm

Luminous intensity:5500~7000mcd @120 degrees

2. Led Appearance: Yellow diffuse with white face support

3. 5.0*5.0*1.5mm standard package

4. Suitable for all SMT assembly methods

5. Compatible with infrared and vapor phase reflow solder process

6. Compatible with automatic placement equipment

7. This product doesn’t contain restriction Substance, comply ROHS standard

8.Compatible with IR Reflow soldering and TTW soldering

9.Pb free product and acceptable lead-free process

10.Anti-electric and moisture free package(2K/Reel)

11.We have the ability to fulfill your customized orders

OEM&ODM available

Application

1.Indoor and out door commercial light

2.LED backlighting and SMD type indicator

3.LED midule and LED strip light

4.Decoration lights

Our Services

1-Customized logo is acceptable

2-Changing the shape, color is acceptable

3-Develop on artwork & development is acceptable

4-Assistant on artwork development is acceptable

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By sea | 30-40 business days |

1. 3-10 business days for Sample Orders; 7-40 business days for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address.

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: What determines the brightness of the patch LED?

- The current through the lamp itself. If the same lamp, so it is necessary to ensure consistency in the different current circuit, the test voltage of little significance, especially in the case of parallel lamp, current a few beads each share is not the same, some big, some small.

- Q: How does the LED placement lamp distinguish the positive and negative poles? There is no sign on the light. Thank you

- You can also use the ohmmeter's ohmmeter. To dial multimeter, to "ohm X1" file, the light emitting diode when the red pen is connected to the positive terminal of SMD LED, the black probe is connected to the negative terminal of SMD LED.

- Q: Is the forward voltage drop of the patch LED too large or too small?

- Pressure drop does not mean good or bad, the greater the pressure drop, the better to choose the right for you

- Q: How to detect LED SMD beads

- The output voltage of the digital clock diode file is not high, generally below 2.5V, so the measurement of LED lamp does not work, the best way is to external electrical measurement. If there are a lot of beads to measure it, can take a constant current power measurement.

- Q: What does patch LED light mean?

- The patch may be said, adding that the patch board PCB light source, light source lamp light source generally refers to, patch may refer to the combination of PCB plate and two lens beads.

- Q: LED patches have several ways of welding. Which ones can be reflow? What can be done by eutectic welding? Is the welding of viscose and lens material is required?

- SMD patch products basically can be used in reflow soldering, especially a little note here that the eutectic welding is the connection between the chip and the substrate support or specifically, is the bottom of the chip after completion of production of coating material and a layer of Sikkim alloy, and then set up a heating zone in solid crystal machine package in time and a temperature of about 300 degrees, the realization process of the chip at the bottom of the Sikkim alloy melt and silver plated layer connection bracket, and a clear distinction between reflow.

- Q: How many volts is a single LED on the LED patch band?

- LED patch lamp is made of FPC circuit board, LED lamp and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.

- Q: What are the storage requirements of SMT patch LED (LED)?

- Moisture-proof packing- anti SMD LED in the transport and storage of moisture absorption, SMD LED shall be placed in sealed moisture-proof bag, inside put damp proof agent for protection, and placed the humidity humidity SMD display card packaging bag.

- Q: Patch LED features

- Without heating time, lighting is faster than general light (about 3 ~ 400ns).The electro optic conversion efficiency is high, the power consumption is small, and the energy consumption is about 1/3 ~ 1/20 than that of the bulb.

- Q: What is the difference in performance between the LED plug-in and the LED patch?

- 1, the patch is relatively easy to heat dissipation, can be directly welded on the aluminum substrate, heat faster.2, in general, there is a straw type shell, general lighting has front facing directivity, just look at it, brightness will be the biggest. The patch has a relatively wide divergence angle and is more suitable for fluorescent lamps.

Send your message to us

5050 SMD LED Chip, High Quality Epistar LED Chip

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 50000 Pcs bag

- Supply Capability:

- 100000 Pcs Per Month bag/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords