Best Galvanized Steel Sheet in Ciols with Best Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

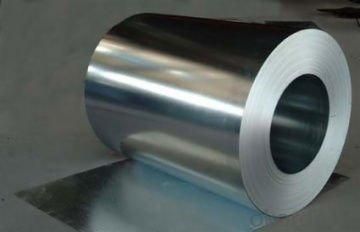

1.Structure of Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc.

2.Main Features of the Galvanized Steel Coil:

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

3.Galvanized Steel Coil Images

4.Galvanized Steel Coil Specification

Zinc coating :40-180g( as required)

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

Coil weight: 4-10 MT(as required)

Surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

Grade : SGCD,SGCH, Q195,DX51D

C

oil id:508mm/610mm5.FAQ of Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

- Q: How are steel coils inspected for oil or rust residues?

- Steel coils are typically inspected for oil or rust residues through visual examination, as well as using various testing methods such as wiping the surface with a white cloth to check for any visible stains or residues. Additionally, some inspectors may also use specialized equipment such as ultraviolet lights or moisture detectors to identify any hidden oil or rust contaminants.

- Q: What are the typical coil width options?

- The typical coil width options vary depending on the industry and application, but common options include 12 inches, 18 inches, 24 inches, and 36 inches.

- Q: I got a muzzy carp point arrow and its head is steel with 1.7% carbon, its used in the water. Will i have to dry it after every use or is it stainless. Thanks

- Stainless steel is not rust proof. it's just rust resistant. It will rust. It just takes much longer to do so... So, yes, I'd dry it well after use, and even consider wiping it with a cloth containing a very lite coating of oil.

- Q: Can steel coils be stored in a corrosive environment?

- No, steel coils should not be stored in a corrosive environment as it can cause damage and corrosion to the coils, reducing their quality and durability over time.

- Q: How are steel coils tested for flatness and straightness?

- Steel coils are tested for flatness and straightness using a variety of methods. One common method is to pass the coil through a series of rollers that apply pressure and measure any deviations in the surface. Another method involves using laser sensors to scan the entire coil and detect any irregularities. Additionally, visual inspections are conducted to identify any visible imperfections or distortions.

- Q: What are the common coil diameter and weight combinations available for steel coils?

- The available combinations of coil diameter and weight for steel coils vary depending on specific requirements and industry standards. However, the market offers commonly used combinations that are widely accessible. Coil diameter commonly ranges from 24 inches (610 mm) to 72 inches (1829 mm). These sizes are often utilized in industries such as automotive, construction, and manufacturing. Coil weight varies significantly based on the steel type and thickness. In the case of hot-rolled coils, the weight typically falls between 5 to 30 metric tons. For cold-rolled coils, the weight usually ranges from 2 to 20 metric tons. Heavier coils are commonly applied in heavy-duty situations, while lighter coils are preferred for delicate or precise applications. It's important to remember that these are general guidelines, and the actual combinations of coil diameter and weight can be customized to meet a customer's specific needs. Different manufacturers and suppliers offer a wide range of options to accommodate various industry requirements. Therefore, it is advisable to consult with the specific supplier to determine the available coil diameter and weight combinations that best suit your application.

- Q: What are the common methods of testing the strength of steel coils?

- Steel coils can be tested for strength using various methods. Tensile testing is one such method, which involves applying tension to the coil until it breaks. This test provides information about the coil's ability to withstand force and its tensile strength. It also reveals details about its yield strength and elongation properties. Another common method is hardness testing, which determines the steel's resistance to indentation or scratching. Different techniques like Rockwell, Brinell, or Vickers tests are utilized to measure hardness. This test helps determine the steel's ability to resist wear or deformation. To evaluate the coil's ductility and flexibility, bend testing is performed. The coil is bent to a specific angle and checked for any signs of cracking or fracturing. Bend testing assesses the material's capacity to withstand bending or forming procedures without failure. Additional methods of testing include impact testing, where controlled impacts are applied to assess the coil's resistance to sudden loading conditions, and fatigue testing, which involves subjecting the coil to cyclic loading to determine its endurance limit and potential for failure under repeated stress. It is important to note that the specific testing methods used may vary depending on the intended application and industry standards. Non-destructive testing techniques, such as ultrasonic testing or magnetic particle inspection, can also be employed to detect internal defects or flaws in steel coils without causing any damage.

- Q: What kind of insulation should be used in a steel building?

- Fiberglass batts or spray on foam both work well

- Q: Ok, so I'm obsessed with learning how to play the guitar (I preffer acoustic)... I'm a teenage girl that wants to play rock/pop/folk music... I want to learn first how to strum... then eventually how to pick...so what type of string is better? nylon or steel?

- Nylon Guitar Strings Vs Steel

- Q: What are the different types of steel coil packaging systems?

- There are several types of steel coil packaging systems available, including horizontal coil packaging machines, vertical coil packaging machines, and coil wrapping machines. Each system is designed to securely package steel coils for transportation and storage, ensuring their protection from damage and corrosion.

Send your message to us

Best Galvanized Steel Sheet in Ciols with Best Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords