Bentonite Geotextile Waterproofing PP Spunbonded Nonwoven Fabric Geotextile Bag - New Arrival in China Market

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of PP Spunbonded Nonwoven Fabric Geotextile Bag:

Geotextile bags and geotubes are extension products of non woven geotextile, nomally made of high-performance PP or PET non woven geotextile.

Main Features of PP Spunbonded Nonwoven Fabric Geotextile Bag:

1. equipment introduced from Italy.

2. Polypropylene (PP) , Polyester (PET) material

Staple fiber ( Short fiber) needle punched

3. weight: 100g/m² to 1200g/m²

4. Customized color and size

Specifications of PP Spunbonded Nonwoven Fabric Geotextile Bag:

| Speccification of nonwoven geotextile bag | |||||

| Weight g/m2 | 110g | 130g | 150g | 300g | 450g |

| Breaking strength KN/M ≥ | 6 | 10 | 12 | 19 | 25 |

| Elongation at braek ≥ | 60% | 60% | 60% | 60% | 60% |

| CBR Mullen Burst Strength KN ≥ | 1.2 | 1.4 | 1.5 | 3.1 | 3.8 |

Applications of PP Spunbonded Nonwoven Fabric Geotextile Bag:

Good filtrations as the pore size are small but the permeability is high.

Protects the terrestrial habitat.

Good abrasive resistance.

Fabric stability is more than in woven fabric

Higher thickness which ensures good puncture resistance

Easily available

Implemented easily

Easy to transport when empty

Available in various sizes to fit specific applications.

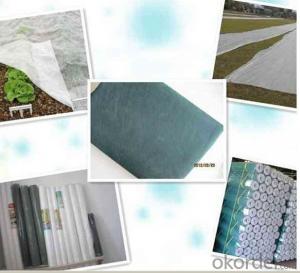

IMages of PP Spunbonded Nonwoven Fabric Geotextile Bag:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What are the cost considerations for geotextile applications?

- Some cost considerations for geotextile applications include the initial purchase cost of the geotextile material, the cost of installation, and any additional costs associated with site preparation and maintenance. Other factors such as the size and complexity of the project, the type and quality of the geotextile material, and the expected longevity of the application also contribute to the overall cost. Additionally, the potential cost savings from using geotextiles, such as reduced construction time and improved long-term performance, should also be taken into account.

- Q: What are the factors to consider when selecting a geotextile for a specific application?

- When selecting a geotextile for a specific application, there are several factors to consider. Firstly, the intended function of the geotextile needs to be evaluated. This includes determining whether it will be used for separation, filtration, reinforcement, or drainage purposes. Secondly, the site conditions and environmental factors such as soil type, climate, and potential chemical exposure must be taken into account. The required strength, durability, and longevity of the geotextile should also be considered. Additionally, the cost-effectiveness and availability of the specific geotextile should be assessed. Finally, the installation and maintenance requirements of the geotextile need to be evaluated to ensure proper implementation and long-term performance.

- Q: What are the factors to consider when maintaining geotextiles?

- When maintaining geotextiles, there are several factors to consider. Firstly, it is important to regularly inspect the geotextiles for any signs of damage or wear. This includes checking for tears, holes, or fraying. Secondly, proper cleaning and maintenance techniques should be followed to ensure longevity. This may involve removing debris or vegetation that could obstruct the performance of the geotextiles. Additionally, it is crucial to consider the environmental conditions in which the geotextiles are installed. Factors such as temperature, moisture, and chemical exposure can impact their performance and require appropriate maintenance measures. Lastly, it is essential to adhere to manufacturer guidelines and recommendations to ensure effective maintenance and maximize the lifespan of the geotextiles.

- Q: Geotextile manufacturers are what industry

- Petrochemical! Raw materials are all extracted from the oil out of the glial particles!

- Q: Roof geotextile isolation layer sets what the amount

- Polyester filament geotextile Features: Polyester filament geotextile is made by polyester method by spinning acupuncture consolidation directly made, product specifications from 80-800g / m2 arbitrary choice, it is geotechnical engineering and civil engineering In the application of a geosynthetics, polyester filament into a network and consolidation method, the fiber arranged in three-dimensional structure. In addition to good mechanical properties, but also has a good vertical and horizontal drainage performance and good extension properties and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, it also has a wide pore size range, tortuous pore distribution, excellent permeability and filtration performance. Polyester filament geotextile Uses: water conservancy project dam and slope protection of the filter, channel isolation, seepage; road, rail, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, Drainage; Port Engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile has been widely used in the field of infrastructure construction, and gradually applied to a wider range of areas.

- Q: How do geotextiles affect groundwater flow?

- Geotextiles can either enhance or restrict groundwater flow depending on their permeability and installation method. Permeable geotextiles can allow water to infiltrate through them, facilitating groundwater recharge and promoting natural drainage. Conversely, impermeable geotextiles can prevent water from passing through, altering the natural flow of groundwater and potentially causing waterlogging or surface runoff issues. The selection and proper installation of geotextiles are crucial to ensure they positively impact groundwater flow and maintain the hydrological balance of an area.

- Q: Geotextile mouth chain suture is what kind of picture

- Hello I am a professional geotextile and other geotextile materials,

- Q: Can geotextiles be used in geotechnical engineering?

- Yes, geotextiles can be used in geotechnical engineering. Geotextiles are permeable fabrics made from synthetic fibers and are commonly used in various geotechnical applications such as soil stabilization, erosion control, filtration, drainage, and reinforcement. They offer numerous benefits in geotechnical engineering projects, including improved soil strength, increased load-bearing capacity, and enhanced drainage and filtration capabilities. Geotextiles are widely employed in the construction of roads, embankments, retaining walls, landfills, and other geotechnical structures to enhance their overall performance and longevity.

- Q: Can geotextiles be used in geosynthetic clay liner caps?

- Yes, geotextiles can be used in geosynthetic clay liner caps. Geotextiles are often used as a protective barrier or separator in geosynthetic clay liner systems to enhance their performance and prevent clogging or migration of fine particles.

Send your message to us

Bentonite Geotextile Waterproofing PP Spunbonded Nonwoven Fabric Geotextile Bag - New Arrival in China Market

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords