Bending Aluminum Sheets - Aluminum Sheet Thickness in All Kinds Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

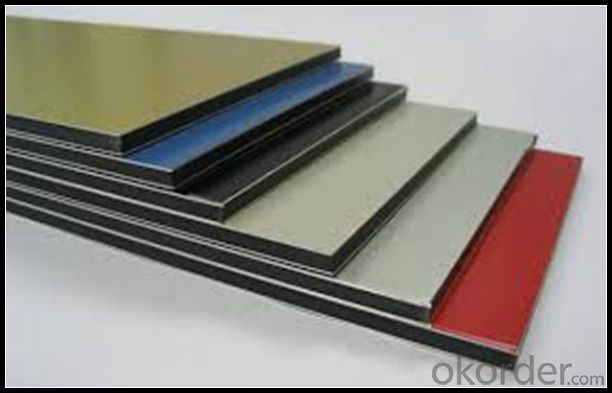

1.Structure of Aluminum Sheet Thickness in All Kinds Supply

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Sheet Thickness in All Kinds Supply

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

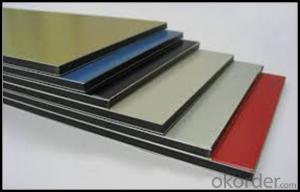

3. Aluminum Sheet Thickness in All Kinds Supply Images

4.Specification of Painted Aluminum Sheet for Composite Panels

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Can aluminum sheets be used for electrical wiring?

- Electrical wiring cannot utilize aluminum sheets. Although aluminum boasts good conductivity, its high electrical resistance renders it unsuitable for such purposes. Copper, on the other hand, is the preferred material for electrical wiring due to its low resistance and superior efficiency in conducting electricity. Moreover, aluminum is susceptible to oxidation, which may result in inadequate conductivity and potential fire risks. Copper wires, on the contrary, are meticulously crafted and produced to comply with electrical safety standards, guaranteeing dependable and secure electrical connections.

- Q: Can aluminum sheets be used for heat dissipation?

- Yes, aluminum sheets can be used for heat dissipation due to their high thermal conductivity.

- Q: I am doing a project on Aluminum it has 13 protons just to make sure everyones on the same page. How much of it is left or exsits? Also how does it behave?

- As Vincent noted, aluminium is an abundant element in the earth's crust. It occurs in all clay minerals. Its main ore, bauxite(a mixture of aluminium hydroxides) is still available in vast deposits; particularly in Australia and South America. Aluminium is a reactive element, and so is not found in nature in the elemental form. Aluminium is a metal, and an amphoteric substance; that is; it reacts with both acids and bases.

- Q: Can aluminum sheet be used for decorative purposes?

- Yes, aluminum sheet can be used for decorative purposes. Aluminum is a versatile material that can be easily shaped, cut, and formed into various designs, making it ideal for decorative applications. It can be used to create decorative panels, sculptures, signage, furniture, and many other decorative elements. Additionally, aluminum can be anodized or painted in a wide range of colors, allowing for further customization and enhancing its aesthetic appeal. Its lightweight nature and resistance to corrosion also make it a practical choice for both indoor and outdoor decorative purposes.

- Q: What are the standard tolerances for aluminum sheets?

- The standard tolerances for aluminum sheets can vary depending on the specific application and industry requirements. However, common tolerances for thickness range from +/- 0.005 to +/- 0.015 inches, while dimensions may have tolerances in the range of +/- 0.030 to +/- 0.125 inches. It is important to consult the appropriate industry standards or specifications for precise tolerances based on the specific needs of the project.

- Q: doesn't particularly need to be welding but i need to make an air tight permanent seal around 2 very thin sheets of aluminium (like .02 inches thick) i was thinking .02 inch 5052 aluminum because its the thinnest i can find but am obviously up for suggestions.

- May be you can use spot welding.But may be that would not give you an air tight permanent seal.So,you can go for Hydraulic pressing as in FERRARI 599 GTO's exhaust.(QUITE EXPENSIVE to be done at personal level)

- Q: Can aluminum sheets be used for honeycomb panels?

- Yes, aluminum sheets can be used for honeycomb panels. Honeycomb panels are typically made by bonding two thin sheets of material, such as aluminum, to a honeycomb core material. Aluminum sheets are commonly used for their lightweight and high strength properties, making them an ideal choice for honeycomb panel construction. The honeycomb structure provides excellent strength-to-weight ratio, making the panels suitable for various applications, including aerospace, automotive, construction, and furniture industries. The aluminum sheets offer durability, corrosion resistance, and ease of fabrication, making them a popular choice for honeycomb panels.

- Q: Carbon costs more than aluminum. But there are manufactures who make high quality alloy frames which costs just as much, if not more slightly than mediocre carbon frames.In your opinion, which is better, stiffer, and lighter?If you need examples....umm like Cervelo's S1 or CAAD9 compared to the lower quality carbon frames.

- A high end aluminum frame would be a better choice than a mediocre carbon frame. Aluminum frames are light, and a good one could well be lighter than a lower end carbon frame. Stiffness is an overrated quality in a frame. A frame that is unrelentingly stiff can beat you up and be a chore to ride. Good frames are stiff where they need to be and compliant in the right places to make them comfortable to ride. Cannondale was one of the first companies to start building quality aluminum frames for road bikes, before any of the other major bike companies on the market today, and they continue to sell high end aluminum bikes today. Early aluminum frames had durability issues, but those problems have been resolved. Frame weight is not much of an issue. Keep in mind that the rest of the components of a bike weigh far more than the frame. You can't turn a 25 pound bike into a 15 pound bike with a better frame, the difference in weight between a top level carbon fiber frame and an aluminum frame will be much less than 1 pound, even a good steel frame will weigh less than 2 pounds more than the lightest carbon frames.

- Q: Can aluminum sheets be anodized for added durability?

- Yes, aluminum sheets can be anodized for added durability. Anodizing is an electrochemical process that forms a protective oxide layer on the surface of aluminum, increasing its corrosion resistance, hardness, and overall durability.

- Q: what kind of abradant should be used in the deburring of aluminum sheets? How to grind?

- you can use deburring brush,grinding fluid,abrasive powder and other consumables.

Send your message to us

Bending Aluminum Sheets - Aluminum Sheet Thickness in All Kinds Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords