BBM 1 Special Building Hoist with Hot Galvanized

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Special Mast Building Hoist Quick Detail

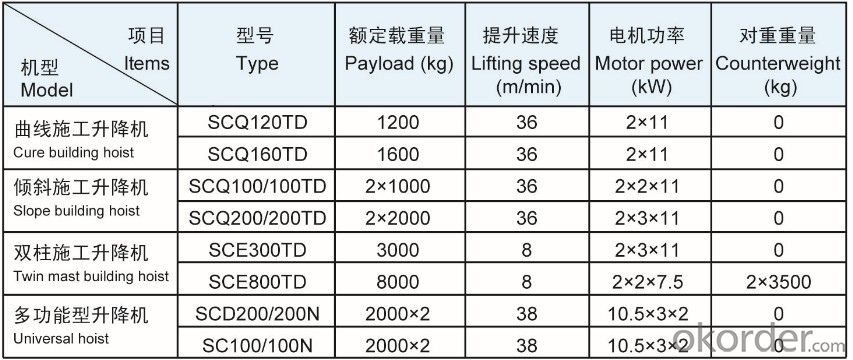

BJB curve building hoist is designed for the construction job on the curved surface of the building, widely applied in the fields of electric power, chemical industry, mineral industry etc. This kind of hoist for the building construction is a certain tilt of the surface of the building.

BJB Slope building hoist is applicable to construction on the slope surface of the building, such as chimney, water tower, bridge etc.This kind of hoist has no counterweight and its mast should be installed in the inclined line (The angle of the mast to the vertical line is≤10°), while the cage floor can be always maintained to the horizontal plane. Its wall-frame can be adjusted with screw to suit the site requirements for different wall-tie length. (The maximum length of wall-tie can be 12 meters). The cage may have driver cabin or not.

Advantages:

BJB twin mast building hoist has unparalleled advantage for the transportation of cage with large tonnage and volume such as three-dimensional parking. This kind of construction hoist is a universal hoist for passengers and materials with a special bucket and a platform to load concrete and super-long steel bar. It is mostly used in construction of cooling tower and chimney of power plant to transport passengers and materials. It can replace the big tower crane and other lifting machine in special construction sites where the working condition is tough. This kind of hoist features is high efficiency and economic operation.

Sepecification

Pictures:

FAQ:

1. Recommended cage dimension (L×W×H) (m):

2.5×1.3×2.5;3×1.3×2.5;3.2×1.5×2.5;5×4×3.2;8×4.8×4

Cage dimension can be made-to-order according to requirements of customer.

- Q: This question asks about the steps or measures to ensure the safe installation of a building hoist, which is a device used in construction for lifting materials and personnel.

- <p>To install a building hoist safely, follow these steps: 1. Ensure the site is clear and secure, with proper access and no obstructions. 2. Check that the hoist is suitable for the load and building structure. 3. Assemble the hoist according to the manufacturer's instructions. 4. Install the hoist on a stable and level base, ensuring it is securely anchored to the building. 5. Conduct a thorough inspection of all components for any defects or damage. 6. Test the hoist with a trial run to ensure all functions work correctly. 7. Train operators on the safe use and operation of the hoist. 8. Obtain any necessary permits and inspections from local authorities. 9. Regularly inspect and maintain the hoist to ensure ongoing safety.</p>

- Q: What are the alternative uses of a building hoist besides construction?

- <p>Yes, building hoists can be used for other purposes beyond construction. They can be utilized in various industries for material handling, such as in warehouses for moving goods, in factories for lifting machinery, and in maintenance for accessing high areas. Additionally, building hoists can be employed in emergency services for rescue operations, especially in high-rise buildings. They are also used in special events for setting up stages and equipment. The versatility of building hoists makes them a valuable tool in many different scenarios where vertical transportation of materials or personnel is required.</p>

- Q: This question asks about the various elements that can influence the efficiency and effectiveness of a building hoist.

- <p>The performance of a building hoist is affected by several factors including the type and weight of materials being lifted, the frequency of use, the hoist's mechanical condition and maintenance, environmental conditions such as wind and temperature, the skill and training of operators, and the design and capacity of the hoist itself. Proper installation, regular inspections, and adherence to safety protocols also play a crucial role in ensuring optimal performance and safety. Additionally, the quality of electrical systems, the efficiency of the drive mechanism, and the structural integrity of the hoist's components can significantly impact its operation.</p>

- Q: This question asks for the criteria or factors to consider when selecting a building hoist for a particular construction task.

- <p>Choosing a suitable building hoist involves considering several factors: the weight capacity required for the materials you need to lift, the height of the building or structure, the frequency of use, and the available space for installation. Ensure the hoist complies with safety standards and regulations. Consider the hoist's speed and efficiency, as well as the ease of maintenance and operation. Consult with hoist manufacturers or experts to assess your specific needs and select the most appropriate model for your construction project.</p>

- Q: This question asks for an explanation of the different types of building hoists used in construction.

- <p>Building hoists, also known as construction hoists or material hoists, are essential for moving materials and personnel in high-rise construction projects. The main types include: 1. <strong>Freestanding Hoists</strong>: These do not require a building structure for support and are self-supporting. 2. <strong>Cladding Hoists</strong>: Attached to the building's facade, used for moving materials during cladding work. 3. <strong>Personnel Hoists</strong>: Specifically designed for transporting workers, ensuring safety with features like cages and safety devices. 4. <strong>Material Hoists</strong>: Built to transport heavy construction materials and are robust and durable. 5. <strong>Electric Hoists</strong>: Operated by electricity, offering precise control and energy efficiency. 6. <strong>Hydraulic Hoists</strong>: Utilize hydraulic systems for lifting, known for their smooth operation and heavy load capacity. Each type serves a specific purpose and is chosen based on the project's requirements and the stage of construction.</p>

- Q: How much cable does the construction elevator 44KVA need?

- 44KW three phase power: 79A, BV5X16

- Q: This question asks about the method to determine the maximum weight a building hoist can safely support.

- <p>Calculating the maximum load capacity of a building hoist involves several factors. First, consider the hoist's mechanical design and the manufacturer's specifications, which provide the rated load capacity. This is the maximum weight the hoist is designed to handle. Next, assess the condition of the hoist, as wear and tear can reduce its capacity. Additionally, consider the strength of the supporting structure and the safety factor, which is typically a multiplier of the rated load capacity to ensure safety. For example, if the hoist is rated for 1000 kg, a safety factor of 1.5 means the actual maximum load should not exceed 667 kg (1000 kg / 1.5). Always consult with engineers and follow local regulations and standards for precise calculations.</p>

- Q: Is it possible to utilize a building hoist to relocate an entire house?

- <p>No, using a building hoist to move a house is not feasible. Building hoists are designed for vertical transportation of materials and personnel within a building, not for moving entire structures. The weight and structural integrity of a house would be too much for a hoist to handle. Additionally, the process of moving a house typically involves specialized equipment and techniques like those used in house lifting and skidding, which are very different from the operations of a building hoist.</p>

- Q: Explain the key differences between electric and pneumatic lifting equipment in a few sentences.

- <p>Electric lifting equipment is powered by electricity and offers precise control, high efficiency, and is suitable for heavy-duty applications. Pneumatic lifting equipment, on the other hand, is powered by compressed air and is known for its simplicity, safety, and lower cost. It is often used in environments where electrical equipment might be hazardous, such as in the presence of flammable gases or dust. Electric systems can handle heavier loads and provide more precise control, while pneumatic systems are more resistant to overload and offer a fail-safe mechanism in case of air pressure loss.</p>

- Q: Should a fire extinguisher be equipped in the construction elevator?

- The dual-purpose construction elevator should be needed

Send your message to us

BBM 1 Special Building Hoist with Hot Galvanized

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords