Construction Hoist Mast Section Hot Galvanizing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Construction Hoist Description

The general building hoist manufactured by our company have the features as good quality, long life, wide application range and convenient for maintenance. The gearing adopted bearing,enameled cable, and oil seal. The electric parts adopt products from worl renowned manufacturers such as Schneider, Siemes, and LG. The racks and pinion adopts specal material and heat-treatment technique, which prolong the life of these parts. The steel structure uses quality steel from famous domestic manufacturers. The cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminum board.

Main Features of Construction Hoist

1. The recomended cage dimension(L*W*H)(m): 2.0*1.0*2.5, 2.5*1.0*2.5, 2.5*1.3*2.5, 3.0*1.5*2,5, 3.2*1.5*2.5, 3.8*1.5*2.5, 4.0*1.5*2.5, 4.2*1.5*2.5 etc. We can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to yout requirements.

3. The mast section and the tie-in surface can adopt paint-spray, or hot galvanizing processing..

Construction Hoist Specifiction

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage building hoist can be changed into single cage type,

| Type | Payload(kg) | Lifting Speed (m/min) | Motor Power(kw) | Safety Device | ||

| Twin Cage Hoist | No Counterweight | SC100/100 | 2*1000 | 33 | 2*2*11 | 2*SAJ30-1.2 |

| SC120/120 | 2*1200 | 33 | 2*2*11 | 2*SAJ30-1.2 | ||

| SC160/160 | 2*1600 | 33 | 2*2*11 | 2*SAJ30-1.2 | ||

| SC200/200 | 2*2000 | 33 | 2*3*11 | 2*SAJ40-1.2 | ||

| SC250/250 | 2*2500 | 33 | 2*3*11 | 2*SAJ50-1.2 | ||

| SC270/270 | 2*2700 | 33 | 2*3*15 | 2*SAJ50-1.2 | ||

| SC300/300 | 2*3000 | 33 | 2*3*15 | 2*SAJ50-1.2 | ||

| SC320/320 | 2*3200 | 33 | 2*3*15 | 2*SAJ50-1.2 | ||

| With Counterweight | SCD200/200 | 2*2000 | 33 | 2*2*11 | 2*SAJ40-1.2 | |

| SCD250/250 | 2*2500 | 33 | 2*2*11 | 2*SAJ50-1.2 | ||

| SCD270/270 | 2*2700 | 33 | 2*2*15 | 2*SAJ50-1.2 | ||

| SCD300/300 | 2*3000 | 33 | 2*2*15 | 2*SAJ50-1.2 | ||

| SCD320/320 | 2*3200 | 33 | 2*2*15 | 2*SAJ50-1.2 |

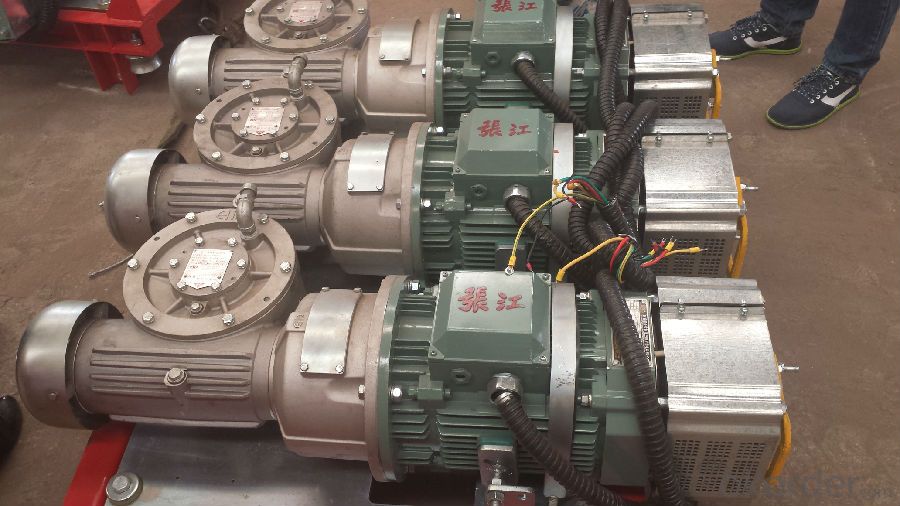

Images of Construction Hoist

FAQ of Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question seeks to understand the benefits and drawbacks associated with the use of hydraulic building hoists in construction.

- <p>Hydraulic building hoists offer several advantages, including high lifting capacity, smooth and controlled lifting, and lower maintenance costs due to fewer moving parts. They are also energy-efficient and can be easily integrated into existing systems. However, they have some disadvantages. For instance, they can be more expensive to purchase initially compared to other hoist types. Additionally, they may require more space for installation and can be sensitive to extreme temperatures, which might affect performance. Lastly, hydraulic systems can be prone to leaks and require regular fluid checks and maintenance to prevent system failure.</p>

- Q: The staff on the construction platform shall not exceed the number of people

- Different models have different load rating and platform lift platform size, this depends, suzhou new aluminium alloy elevator, Lin professional aluminum alloy lift platform.

- Q: This question asks for the method to determine the maximum load that a single-rope lift can handle.

- <p>To calculate the load capacity of a single-rope lift, you need to consider several factors including the strength of the rope, the diameter of the rope, the angle of the lift, and the safety factor. The basic formula involves determining the maximum load the rope can bear based on its material properties and construction, which is then adjusted by the safety factor to account for dynamic loads and potential wear. The formula might look something like this: Load Capacity = (Tensile Strength of Rope 脳 Area of Rope Cross-Section 脳 Safety Factor) / (Cosine of Angle of Incline). It's important to consult with engineering standards and the lift manufacturer's specifications for precise calculations.</p>

- Q: This question asks for a description of the process of using an emergency stop button specifically in the context of a building hoist.

- <p>To use an emergency stop button on a building hoist, first, ensure you are familiar with the hoist's controls and safety features. Locate the emergency stop button, which is typically a red mushroom-shaped button or switch, prominently placed and easily accessible. In an emergency, press and hold the button firmly. This action will immediately stop all hoist functions, including movement and operation. After pressing the emergency stop, evacuate the area if necessary and notify the appropriate personnel to address the situation. Remember, the emergency stop should only be used in situations where immediate action is required to prevent harm or damage. Regular training and drills can help ensure you are prepared to use the emergency stop button correctly and effectively.</p>

- Q: Is it possible to operate building hoists in cold weather conditions?

- <p>Yes, building hoists can be used in cold climates, but they must be designed and maintained for such conditions. Cold weather can affect the performance of hoists, so it's crucial to use hoists specifically engineered for low-temperature operation. Regular maintenance and checks are necessary to ensure safety, as extreme cold can cause metal parts to contract and lubricants to thicken, affecting the hoist's functionality. Always follow the manufacturer's guidelines for operating hoists in cold climates.</p>

- Q: Is it possible to utilize a building hoist for construction purposes?

- <p>Yes, a building hoist is specifically designed for use in construction work. It is a type of lifting equipment used to transport materials and personnel vertically within a building under construction. Building hoists are essential for efficient material handling, reducing manual labor, and ensuring the safety of workers by providing a stable and controlled method of vertical transportation. They are commonly used in high-rise construction projects and are an integral part of the construction process.</p>

- Q: This question asks for methods to reduce the time a lifting device, such as a building hoist, is not operational and the expenses associated with its upkeep.

- <p>Minimizing downtime and maintenance costs for lifting equipment, including building hoists, involves a combination of proactive measures and regular maintenance. Implement a preventive maintenance schedule to address potential issues before they cause significant downtime. Use high-quality components to reduce the frequency of repairs. Train operators to handle equipment correctly and perform basic troubleshooting. Regularly inspect and lubricate moving parts to prevent wear and tear. Implement a condition monitoring system to detect early signs of malfunction. Finally, keep spare parts readily available to expedite repairs and minimize downtime.</p>

- Q: This question asks about frequent issues related to building hoists and seeks solutions for these problems.

- <p>Common problems with building hoists include mechanical failures, electrical issues, overloading, and safety malfunctions. Mechanical failures can be fixed by regular maintenance, lubrication, and replacement of worn parts. Electrical problems may require checking wiring, connections, and replacing faulty components. Overloading can be prevented by strictly adhering to the hoist's weight limit and using load indicators. Safety malfunctions, such as brake failure, require immediate attention and may involve replacing brake pads or overhauling the braking system. Always ensure that hoists are used according to the manufacturer's guidelines and are regularly inspected by qualified personnel to prevent accidents and ensure safe operation.</p>

- Q: This question asks whether a building hoist can be used in both indoor and outdoor construction settings.

- <p>Yes, a building hoist can be used both indoors and outdoors for construction work. These hoists are versatile and designed to facilitate the movement of materials and personnel in multi-story buildings. Outdoors, they are often used during the construction of high-rise buildings, while indoors, they can be used for the vertical transportation of materials in large structures like shopping malls or office buildings. It's important to ensure that the hoist is suitable for the specific conditions, such as weather resistance for outdoor use, and that safety protocols are strictly followed to prevent accidents.</p>

- Q: What is the meaning of double straps in the construction elevator?

- Used for heavy to offset the hoisting cage weight so as to realize energy-saving province electric hoist, by making use of the fixed pulley for heavy gravity into upward traction hanging basket of traction, so as to reduce the drive motor load, achieve energy saving.

Send your message to us

Construction Hoist Mast Section Hot Galvanizing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords