Best Selling Ball Valve Metal Ball EN Standard API Rotating Position Belt Transmission

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Ball Valve

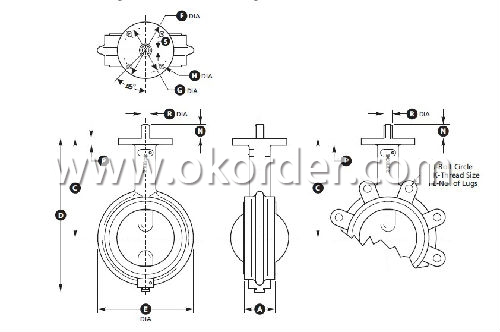

Standard: Left side big than the Right side after a big flanges , D1 and the reaction kettle connection, the molecules to right flange size, the common denominator for left JB78 flange size, match the reaction kettle 50 L-5000 L.

1. Should stay the valve handle rotating position

2. Not to be used as throttling.

3. The belt transmission's ball valve should be installed upright.

4. Please use the product according to the right, to ensure that the service life of the product, such as unusual situation, that is, please call national unified service hotline 400-666-1929, we will provide you with the high quality post-sale service, give you a satisfactory reply.

- Q: What q25r-j159 BB-F-TE-NB represents American Standard ball?

- American Standard top mounted hard seal fixed ball valve modelQ: valve type - ball valve, BALL, VAVE2: pressure class -150cl pounds scale5: structural form - tethered body, top mounted, fixed ball (abbreviated BB-F-TE-NB)R: connection form -RF convex mesa flange connectionJ1: body material -A216-WCB cast carbon steel59: spool material -13%Cr

- Q: What does W represent in copper ball valve Q11W-16T?

- Valve sealing materials are all valves of the body material, sealing surface material code with "W" said

- Q: The difference between a cricket valve and a constant pressure valve

- Ball valve for ball ball column shape and called, is mainly to be closed, and often switch when the fluid flow control to throttle function and design, is the main characteristic of effective throttling, to minimize and reduce the phenomenon of drawing valve and valve seat dip (wash) inhibition, but because of the seat is parallel to the line, change the flow of fluid through the valve seat will be in class.

- Q: What is the difference between PPR ball valve and PPR live ball valve?

- PPR and PPR union ball valve is different: PPR union ball valves and pipes on both sides (hot melt) connected between, a movable joint (hot melt) and (link with) nut, maintenance, convenient disassembly and replacement of the valve, the union not only cut off the PPR ball, maintenance.

- Q: What are the advantages and disadvantages of the two functions of the pneumatic ball valve actuator?

- From the above work principle can be seen: double acting pneumatic actuator, valve opening and valve closing all need compressed air thrust to perform. That is to say, the pneumatic actuator will remain in a position in case of loss of air.The single acting actuator belongs to the automatic reset type. After losing the continuous air pressure, the actuator will drive the valve back to the initial setting position under the tension of the spring.This answer is recommended by users

- Q: What does "ball Q41F-16" mean?

- Q- ball, 4- flange connection, 1- DC channel, floating ball, F- sealing material for fluorine plastic, 16- nominal pressure of 16 kg, the valve body material for gray cast iron. If you want to know the details of the valve named model establishment, can refer to the JBT-308-2004 standard.

- Q: What is the diameter of the 2 inch ball valve?

- 2 inch ball valve, diameter is two inches.Turn left and turn right |Ball valve, standard GB/T21465-2008 "valve terminology" is defined as: open and close parts (spheres) driven by the stem, and around the axis of the ball valve to rotate the valve movement. Can also be used to regulate and control fluid, strong shear force between the metal seat seal V type ball valve V type ball core and welding hard alloy, especially suitable for containing fibers, small solid particles and other media. Switch and multi way valve in the pipeline not only can flow, and flow diversion, flexible control of the medium, but also to turn off any channel to the other two channels. This kind of valve should be installed horizontally in the pipeline. In accordance with the way to drive the ball valve is divided into: pneumatic ball valve, electric ball valve, manual ball valve.Turn left and turn right |The answer is recommended by He Xiaoqiang, a member of the science education category

- Q: What is retractable hemispherical valve? What's the area with the manual hemisphere valve?

- Telescopic hemisphere valve is a telescopic hemisphere valve, ordinary hand hemisphere valve, of course, without expansion joints.Telescopic ball valve is a combination of expansion joint and ball valve. It has the telescopic deformation caused by heating and absorbing the axial, transverse and angle of the absorption pipeline. Absorb the vibration of equipment and reduce the influence of equipment vibration on pipeline.

- Q: Allowable leakage on ball valves: what does CLassVI mean?

- This is the valve leakage level, level VIThe GB/T4213-92 standard specifies six grades for the valve leakage. The specific requirements are shown in the standard table. The lowest level is level I, without specific requirements; the highest level is grade VI, i.e., the bubble grade.

- Q: Three electric ball valve type T and type L what is the difference?

- Electric three way ball valve is a kind of valve, can be divided into L and T type.The T type can cause three orthogonal pipes to connect with each other and cut off third channels, thus diverting and merging the channels.Two pipeline L three ball type valve can only be connected mutually orthogonal, communicating with each other while maintaining the third pipeline, only as a distribution function.Type T and L type reversing diagrams are as follows:Turn left and turn right |

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2004 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; MidEast; Africa; Oceania; East Asia; Europe; Japan; Southeast Asia |

| Company Certifications | ISO 9001:2008; CE; API-6D |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Wenzhou |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 101-200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 8000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Best Selling Ball Valve Metal Ball EN Standard API Rotating Position Belt Transmission

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches