Ball Mill Liner Plate With Alloy Steel Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Mill Liner Plate With Alloy Steel Materials

Alloy steel is steel that is alloyed with a variety of elements to improve its mechanical properties.In wear resistant industry,Chromium,Mo,Nickle are added into carbon steel to achieve wear resistance and corrosion resistance properties.

In our company ,we divide alloy steel into 6 groups according to the element be added:

Low chromium Alloy Steel(Cr2)

Medium Chromium Alloy Steel(Cr5)

Cr-Mo Alloy Steel (Cr5Mo)

Cr-Mo Ni Alloy Steel(Cr5MoNi)

Low carbon high chromium Alloy Steel(Cr8Cu)

Low carbon Mo-Cr-Ni Alloy Steel

| Name | C | Mn | Cr | Si | S,P | Cu | Mo | Ni |

Cr2 | 0.3-1.2 | 0.3-1.5 | 1.0-3.0 | 0.3-1.5 | ≤0.06 | |||

Cr5 | 0.3-0.65 | 0.3-1.2 | 4.0-6.0 | 0.3-1.2 | ≤0.06 | |||

Cr5Mo | 0.3-0.65 | 0.3-1.2 | 4.0-6.0 | 0.3-1.2 | ≤0.06 | 0.3-1.0 | 0.3-1.0 | |

Cr5MoNi | 0.3-0.65 | 0.3-1.2 | 4.0-6.0 | 0.3-1.2 | ≤0.06 | |||

Cr8Cu | 0.2-0.35 | 0.3-1.2 | 6.0-9.0 | 0.3-1.2 | ≤0.06 | 0.3-1.0 | ||

Cr8MoNiCu | 0.2-0.35 | 0.3-1.2 | 6.0-9.0 | 0.3-1.2 | ≤0.06 | 0.3-1.0 | 0.3-1.0 | 0.3-1.0 |

The mechanical property after heat treating:44-54HRC;10-60J/cm2

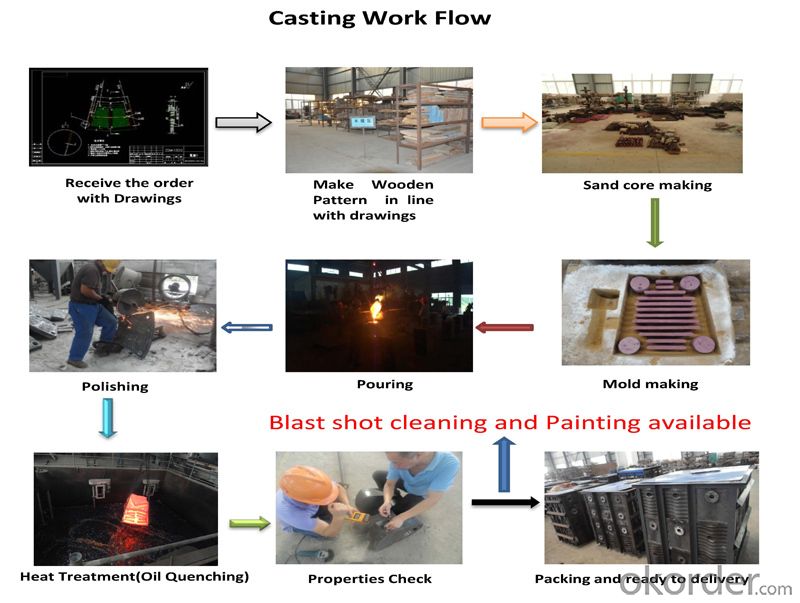

Heat Treatment Method

1.Oil Quenching

Fog Quenching

Tempering:

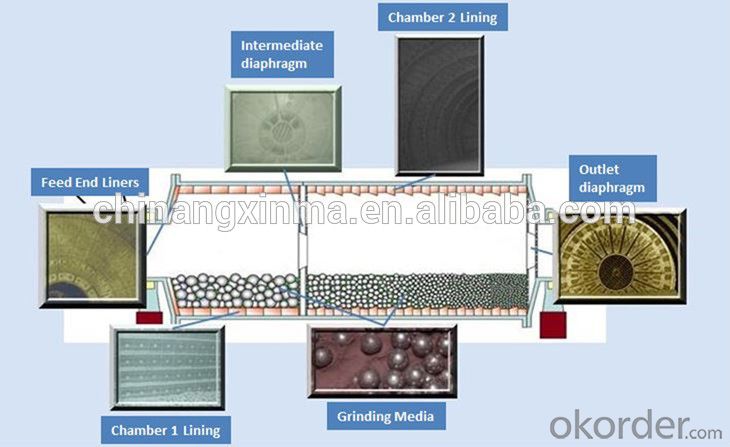

The other products we offer for ball mill as the following picture

Company Information

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Use the vibrator to polish the material: the high aluminum porcelain 4cm (with a polishing agent that has an automatic mending function), you go find this polish,

- Q: The casting sand is going on

- 3, prevention measures(1) to improve the strength of sand mold (core), especially surface strength, high temperature strength, refractoriness, compact, better coating, good core coating and parting surface coating.(2) mould and box can prevent damage;(3) the core should have clearance.

- Q: What method of casting does not rust? I think the sample is like oil

- The surface of a general casting is easy to rust. In order to prolong the rusting period, antirust paint or antirust oil is usually sprayed. What you said should be anti rust oil.

- Q: What's the density of the cast iron? The density is thin and the density is thin

- There is a hot knot in the thick area, which easily causes microscopic shrinkage and makes the casting not dense. A riser may be added for shrinkage relief.

- Q: How to cast iron and wrought iron collocation

- 3, if you have a file in the hand, can be used to file to see finish can also make a judgment from the file down the iron can also be seen, but this is beyond your request, it can be done in the factory. 4, if placed in the grinder grinding, see iron spark from a judge or iron wrought iron, but this is only to do in the factory. About it, may not be full, but through these methods, generally can distinguish between iron or wrought iron.

- Q: Where is the precision casting factory?

- The National Precision Casting Factory is generally distributed in Shandong, Ji'nan, Jiangsu, Wuxi, Changzhou, Zhejiang, Guangdong, Panyu, Dongguan.The above are only the main distribution, many of Shandong are made supercharger, and Guangdong to jewelry industry based.

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- For example Changchun FAW, under a casting, two casting and other casting plant, but there are more than half of all outsourcing in Tianjin Hebei Shandong purchase, many automobile enterprises to casting foundry.

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Personal advice:Because of the large margin, your outline is easy to guarantee;So the key is to consider the assembly and aesthetics of the casting. You have to find the machining criteria;Rough the datum so that it can be machined;After the outline, turn back to the finishing line.If the casting requirement is not high, the benchmark can be directly processed; (not recommended)Over

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Usually manual molding optional CT11 class, ordinary machine modeling optional CT10 class, high pressure molding should reach CT9 level. The tolerances on the wall thickness of the casting are comparable to those of other dimensions of the same casting.

- Q: ZGMn13 casting parts processing, with what knife head good?

- The ZGMn13 itself is not have processing, if only the processing point, sharpening, ordinary can, if the processing area is relatively large, ZGMn13 external impact load is bigger, its surface wear resistance is high; the two is with the gradual wear of surface hardening, the hardening layer is continuously formed new if you have suggestions, processing, plasma cutting or flame cutting try

Send your message to us

Ball Mill Liner Plate With Alloy Steel Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords