Axially Split Casing Multistage Centrifugal Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit unit

- Supply Capability:

- 500 Units/Year unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

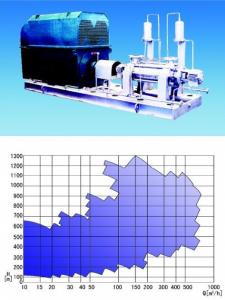

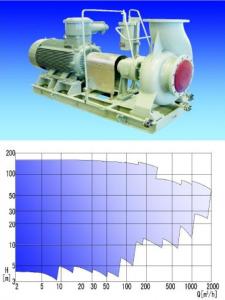

1. Performance Range of Axially Split Casing Multistage Centrifugal Pump

1) Capacity: Q up to 6000 m3/h (26400 gpm)

2) Head: H up to 1200 m (3600 feet)

3) Temperature: T up to 200 (380)

4) Speed: N 2900/1450/980rpm

5) 3500/1750/1180rpm

2. Description of Axially Split Casing Multistage Centrifugal Pump

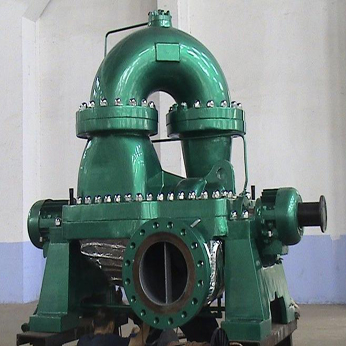

Horizontal axially split casing, double volute multistage design. Impellers arranged in opposed groups, KSY is a double suction two stage pump for bigger capacity. KDY is multistage single suction impeller pump

for higher head, first stage double suction impeller design for low NPSH required. Removable wear rings protect the casing and impeller. The impellers are statically and dynamically balanced. The pump comply

with the API 610 specification latest edition in all technical details. Special antifriction bearings on both sides or sleeve bearings with ring or forced-feed lubrication (axial bearing as segmental thrust bearing).

3. Standard material of Axially Split Casing Multistage Centrifugal Pump

According to API 610 Eighth Edition, August, 1995.

Place of Origin | China (Mainland) |

Brand Name | CNBM PUMP |

Model Number | KDY or KSY |

Theory | Centrifugal Pump |

Structure | Multistage Pump |

Usage | Oil |

Power | Electric |

Standard or Nonstandard | Standard |

Fuel | Other |

Pressure | High Pressure |

Head | up to 1200m |

Capacity | up to 6000m3/h |

Speed | 50Hz/60Hz |

Minimum Order Quantity | 1 Unit |

Delivery Time | 4 Months |

Payment Terms | L/C; T/T |

Supply Ability | 500 Units Per Year |

4. Application of Axially Split Casing Multistage Centrifugal Pump

1) Oilfields and Terminals

2) Crude oil and oil product pipeline

3) Water pipelines

4) Fluid injection

5) High pressure services

6) Sea water

- Q: What is the effect of excessive oil on the oil pump?

- The oil pump doesn't work, but it has an impact on the engine. It makes the engine weak and has a lot of carbon for a long time. Don't ask how I know it. It's still in the car.

- Q: 3000 Zhijun hydraulic top rattled, replaced the hydraulic top oil pump, filter base cleaning, cleaning oil. Still ring.

- There is an oil return valve on the oil filter seat. And is the oil bottom connected to the oil pump net?!

- Q: Audi a6l2.0 engine oil pump timing, right?

- This newspaper, engine type, check the information I gave you

- Q: What are the problems caused by engine oil pump damage?

- The damage to the diesel engine oil pump will cause the following problems and solutions:(1) the oil inlet and outlet pipe of the oil pump is leaking at the joint, the oil pump stops supplying oil, and the inlet and outlet pipe gaskets are replaced, and the sealing surface is tightly sealed.(2) oil pump, check valve and seat surface wear or damage, failure, the oil pump does not supply oil, grinding, check valve seat surface or replace the check valve.(3) the oil pump piston wear and seal failure, the oil pump to stop oil supply, replace the piston treatment.(4) the oil pump piston spring is broken, the oil pump fails, the piston pump oil function is stopped, the oil pump is not supplied, the piston is replaced and the piston is taken off.(5) the oil seal of the piston rod of the oil pump is damaged, which causes the diesel oil to enter the injection pump cam chamber, and makes the engine oil of the diesel engine bottom oil become thinner. At this point, the oil seal of the top rod should be replaced.

- Q: Will it clog up the oil pump by cleaning the engine oil which is strong enough to clog up the oil circuit?

- Not recommended, if you want to deal with the best in time to repair the engine oil, the remaining half after adding detergent, appropriate to start the engine, but don't let the engine run continuously, repeated ignition immediately stop, the three stop 5 minutes during the three times, then stop for 1 hours, began to disassemble the bearing replacement of oil with high pressure gas to clean up, and then the parts are cleaned, the abnormal wear or exceed the wear limit of a replacement, beginning of assembly, assembly of lubricating parts with clean oil, oil filter assembly, oil filter oil filling. Start OK.The use of cleaning function of the engine oil will lead to dirt in the oil pipe to fall off, plug the oil on the part of the small hole, exacerbated by the need for lubrication parts of the abnormal wear and tear, serious machine scrapped. The loss outweighs the gain。I have seen the use of this detergent containing oil, after the use of the whole machine scrapped, the landlord carefully.

- Q: Why is the Honda engine oil pump so big? What's the function of the other parts?

- Hello, here is the balance shaft.

- Q: How to change the diesel engine oil pump?

- First of all, you need to release all the oil, disassemble the engine oil pan, remove the oil pump assembly and replace it.The oil pump is the main component in the lubrication system of diesel engine. Its function is to press the engine oil to a certain pressure and force it to the moving surface of the engine parts. The structure of oil pump can be divided into two types: gear type and rotor type. Gear type oil pump is divided into internal gear type and external gear wheel type, generally referred to as gear pump.

- Q: What are the causes of motorcycle engine oil pump damage?

- The oil is bad and the oil is not changed regularly

- Q: Does the new gasoline pump affect the car?

- The car's new oil pump has virtually no effect

- Q: How long will the oil pump lubricate the engine parts after the engine is started?

- 1-3 minutes, the cold car is usually 3 minutes after refueling, the door started.

1. Manufacturer Overview

| Location | Hunan,China |

| Year Established | 2006 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 59.00% Mid East 8.00% North America 8.00% Southern Europe 5.00% Eastern Asia 2.00% Africa 2.00% Oceania 2.00% Southeast Asia 2.00% Western Europe 2.00% South America 2.00% Central America 2.00% Northern Europe 2.00% Eastern Europe 2.00% South Asia 2.00% Domestic Market |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | SHANGHAI,GUANGZHOU,DALIAN |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | High and/or Average |

Send your message to us

Axially Split Casing Multistage Centrifugal Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit unit

- Supply Capability:

- 500 Units/Year unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches