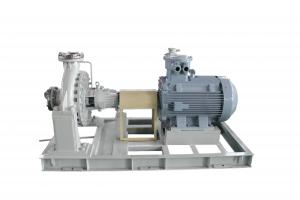

Multistage Heavy Duty Axially Split Casing Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description

Horizontal axially split casing, double volute multistage design.

KDY is multistage single suction impeller pump for higher head.

KSY is double suction two stages pump for bigger capacity.

Removable wear wings protect the casing and impeller.

The pump comply with the API610 specification latest edition in all technical details.

Special antifriction bearings on both sides or sleeve bearings with ring or forced-feed lubrication(axial bearing as segmental thrust bearing)

2. Application

Oilfields and termincals

Crude oil and oil product pipeline

Water pipelines

High pressure services

Sea water pumping

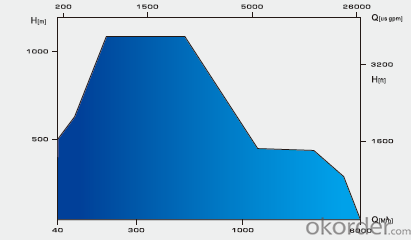

3. Technical Data

Capacity uo tp 6000m3/h (26400gpm)

Head up to 1200m (3500feet)

Temperature up to 200℃ (380F)

4. Pump Performance

5. FAQ

1 Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

2 Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

3 Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

4 Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

- Q: What is the chemical pump for delivering low temperature brine?

- Ordinary magnetic pumps are also available, 304316 of them can. Can go to the site of the site, there is a detailed description of the brine pump, ha ~!

- Q: Slag pump is a chemical pump, or what pump is used to do what, the general price of how much ah?

- Slurry pump, as its name suggests, is the medium conveying slag, abrasive or corrosive pasteApplications are mainly used in environmental protection, sewage treatment, mining, metallurgy, municipal, lake dredging, sand mining, coal, electricity, chemicals, building materials and other industriesPrice, the price of different models is very different

- Q: What are the types of pumps used in chemical plants?

- What are the working conditions?.. What kind of pumps do you use?

Send your message to us

Multistage Heavy Duty Axially Split Casing Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords