ASTM A106Gr.B seamless steel pipe FOR HOT SALE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 3 - 60 mm | Section Shape: | Round | Outer Diameter: | 22 - 508 mm |

| Place of Origin: | Shandong China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Fluid Pipe |

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Other |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Grade: | 20#,45#,16Mn,A53(A,B),A106(B,C),A312,API J55,API K55,API N80,API L80,St37,St52,Q345,10#-45#,A53-A369,API J55-API P110,ST35-ST52,Q195-Q345 |

| Standard: | GB 3087-1999,GB/T 8163-1999,GB/T 8162-1999,ASTM A106-2006,ASTM A312-2001,ASTM A53-2007,API 5CT,API 5L,GB,ASTM,API |

Packaging & Delivery

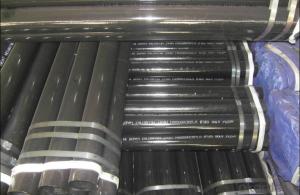

| Packaging Detail: | black painting, plastic caps on both ends, according to customer's requirements |

| Delivery Detail: | 20-30 days |

Specifications

1. Min Order : 20 tons

2.OD: 20mm --508mm

3. WT: 3mm -- 60mm

4.Certification: ISO & API

ASTM A106 seamless pipe/ms pipes

Hot rolled seamless steel pipes

1) Standard: API Standard:ASTM A106.ASTM A53,ASTM A135,ASTM A179,ASTM A214,ASTM A192,ASTM A226,ASTM A315,ASTM A178,ASTM A210,ASTM A333,ASTM A355,ASTM A369,ASTM A334 ASTM/ASME A312/SA312, ASTM/ASME A213/SA213, ASTM A269,ASTM 511,API5L,API5CT, GOST 9940,GOST 9941,JIS G 3459, JIS GS3463, GS3467, JIS G3448, DIN EN 10216-2006(DIN 17458) , DIN EN 10297-2006(DIN 17456) etc.

2) Steel Grade: ASTM A106 GRB,A53 GRB. API 5L GRB,API 5 CT N80,K55,A335 P11.P91,DIN ST52,ST44,ST35.8,ST37,ST42,ST45

3)Outside Diameter:1/2"-20" Or 21.3-508mm

4) Wall Thickness: 3-40mm

5) Application: The products are widely used in fertilizer, petroleum, central-station, boiler, power station, shipping military, chemical industry, environment protection, traffic, metallurgy and mine, printing and dyeing, food industry, medical equipment, and so on.

Production Equipment :

30 sets of Cold-drawn Machinery (Model: 3 ton to 500 ton)

Cold-rolled Machinery: Model LD-30, LD-60, LG-90H (L), LG-159H (L)

Automatic Roller Solution & Annealing Heat Treatment Equipment

18-meter-long Pickling Sin

QUALITY ASSURANCE:

1) Strictly acc. ASTM,DIN,JIS,EN,GOST etc

2) Sample: We are accept your sample requirement

3) Test: Eddy current / hydrostatic/ Ultrasonic/ Intergranular Corrosion or according to customers' request

3) Certificate:API, CE ,ISO9001.2000.MTC etc

4) Inspection: BV,SGS,others is avaliable.

High Quality Package :

1) In bundle with strip;

2) First packing by plastic bag then strip; Details packing please see the picture in the detial description.

3) In bulk

4) Client' requirements

5) Delivery: 1) Container: 25 tons/container for pipe with usual outer diameter. For 20" container the max length is 5.8m; For 40" container the max length is 11.8m.

2) Bulk carrier: It is no requirements to the length of the pipe. But its booking space time is long.

Our Advantages:

1) Fast Delivery: around 10days below 50Metric Tons after sight of Irrevocable L/C or Deposit;(lot of high quality steel pipe in stock)

2) Quality Assured: Strictly acc. To International standard ASTM & BS & EN & JIS, with System ISO certification

3) Good Service: supplied professional technical guide free of charge at anytime;

4) Reasonable Price: to be better support your business;

- Q: How do steel pipes compare to other materials in terms of cost?

- Steel pipes are generally more cost-effective than many other materials used for pipes, thanks to their durability, strength, and availability. While initial costs may vary depending on factors like size and grade, steel pipes offer a longer lifespan and require less maintenance compared to other materials, making them a cost-efficient choice in the long run.

- Q: What is the maximum temperature that steel pipes can withstand?

- The maximum temperature that steel pipes can withstand depends on the grade and type of steel used. Generally, carbon steel pipes can withstand temperatures up to 1000°C (1832°F), while stainless steel pipes can handle temperatures up to 1200°C (2192°F). However, it is essential to consult the specific specifications and guidelines provided by the manufacturer for accurate temperature limits.

- Q: What are the different end finishes for steel pipes?

- There are several different end finishes for steel pipes, depending on their intended use and the specific requirements of the application. Some of the most common end finishes for steel pipes include: 1. Plain End: This is the simplest and most common type of end finish, where the pipe is cut square at both ends without any additional treatment or threading. Plain end pipes are typically used for low-pressure applications or when the pipe will be connected using welding methods. 2. Beveled End: A beveled end finish involves cutting the pipe at an angle, usually 30 or 37.5 degrees, to facilitate easier welding and create a stronger joint. Beveled end pipes are commonly used for butt-welding applications, where two pipes are joined together by aligning the beveled ends and welding them. 3. Threaded End: In this end finish, the pipe is threaded at both ends to allow for easy connection with threaded fittings or couplings. Threaded end pipes are commonly used in plumbing and gas distribution systems, as well as for applications that require frequent disassembly and reassembly. 4. Coupled End: Coupled end finishes involve the installation of couplings or connectors at each end of the pipe. This allows for quick and easy connection of pipes without the need for additional threading or welding. Coupled end pipes are often used in oil and gas pipelines or in applications where rapid installation is required. 5. Grooved End: A grooved end finish involves cutting grooves into the pipe's ends and using mechanical couplings or fittings to join the pipes together. This type of end finish is commonly used in fire protection systems, as well as for large-diameter pipes that require quick and efficient assembly. 6. Flanged End: Flanged end finishes involve attaching flanges to the pipe ends, which can be bolted together to create a secure and leak-proof connection. Flanged end pipes are commonly used in applications that require easy disassembly and reassembly, such as in chemical plants or refineries. It is important to note that the choice of end finish for a steel pipe depends on factors such as the application, the required joint strength, the type of connection method, and the compatibility with other system components. Consulting with a professional or referring to industry standards is recommended to ensure the correct end finish is selected for a specific application.

- Q: What are the different types of pipe coatings used for corrosion protection?

- There are several types of pipe coatings used for corrosion protection, including epoxy coatings, polyethylene coatings, polyurethane coatings, and zinc coatings. Each type of coating offers specific advantages and is chosen based on factors such as the type of corrosive environment, the desired level of protection, and the budget constraints.

- Q: Can steel pipes be used for pharmaceutical manufacturing?

- No, steel pipes are not typically used for pharmaceutical manufacturing as they can pose a risk of contamination and corrosion. Instead, pharmaceutical manufacturing typically relies on materials such as stainless steel or specialized polymers that are more suitable for maintaining sterile conditions and ensuring product purity.

- Q: What are the different types of connections used with steel pipes?

- The different types of connections used with steel pipes include threaded connections, welded connections, and flanged connections.

- Q: How do you prevent steel pipes from freezing in cold climates?

- One way to prevent steel pipes from freezing in cold climates is by insulating them with materials such as foam insulation or heat tape. This helps to maintain the temperature of the pipes and prevents them from freezing. Additionally, ensuring that all cracks or openings in the walls or foundation where the pipes are located are sealed can also help in preventing the pipes from freezing.

- Q: How are steel pipes used in the mining industry?

- Steel pipes are commonly used in the mining industry for various purposes such as transporting minerals, water, and gases underground, as well as for constructing mine shafts, tunnels, and mine infrastructure due to their durability, strength, and resistance to corrosion.

- Q: Can steel pipes be used for oil refineries?

- Yes, steel pipes can be used for oil refineries. Steel pipes are commonly used in oil refineries due to their high strength, durability, and resistance to corrosion. They can handle the high pressure and temperature requirements of the oil refining process, making them suitable for transporting and distributing various petroleum products within the refinery.

- Q: How do you calculate the pipe friction loss coefficient for steel pipes?

- To determine the pipe friction loss coefficient for steel pipes, it is necessary to take into account several factors. One commonly used approach is the utilization of the Darcy-Weisbach equation, which establishes a relationship between the frictional head loss in a pipe and the flow rate, pipe diameter, pipe length, fluid properties, and the pipe roughness coefficient. The Darcy-Weisbach equation can be presented as follows: The head loss due to friction, denoted as hf, can be calculated using the formula (f * L * V^2) / (2 * g * D), where: - f represents the pipe friction factor, - L corresponds to the pipe length, - V denotes the fluid velocity, - g symbolizes the acceleration due to gravity, and - D represents the pipe diameter. Determining the pipe friction factor, f, is crucial. For steel pipes, this factor relies on the pipe roughness coefficient, which indicates the relative roughness of the pipe. The relative roughness is determined by dividing the absolute roughness of the pipe surface by the pipe diameter. The pipe roughness coefficient can be obtained from different sources, including manufacturer specifications, engineering handbooks, or experimental data. It is imperative to ensure that the roughness coefficient used aligns with the specific type and condition of the steel pipe under analysis. Once the pipe roughness coefficient is obtained, it can be employed to calculate the pipe friction factor through empirical correlations or charts. These correlations often involve the Reynolds number, a dimensionless quantity that characterizes the flow regime. By substituting the determined pipe friction factor into the Darcy-Weisbach equation, it becomes possible to calculate the head loss due to friction for steel pipes. This value is indispensable in the design of piping systems, determination of pump requirements, or estimation of energy consumption in fluid flow applications.

Send your message to us

ASTM A106Gr.B seamless steel pipe FOR HOT SALE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords