Seamless Black Carbon Steel Pipe Of API 5L

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1、Structure of Seamless Black Carbon Steel Pipe Of API 5L Description:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of the Seamless Black Carbon Steel Pipe Of API 5L:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

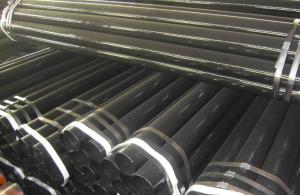

3、Seamless Black Carbon Steel Pipe Of API 5L Images:

4、Seamless Black Carbon Steel Pipe Of API 5L Specification:

Standard | GB, DIN, ASTM |

Grade | 10#-45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

(1) application

carbon seamless steel pipes are widely used in gas, water and oil, transpotation;constructions;Bridge,highway,windows of model steel door; building materials;fences;heating facilities Fluid Pipe;conduit pipe,scaffolding pipe.etc.

(2)packing and shipment

Packaged in bundles,as per customers' requirements, it can also bepackagesd as beveled ends, typed marking, black painting, plastic caps protection,woven bags packing

For 20" container the max length is 5.8m; For 40" container the max length is 12m. other options are available based on customer requests. Please discuss when placing orders.

5、FAQ of Seamless Black Carbon Steel Pipe Of API 5L:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: Can steel pipes be used for conveying sewage and wastewater?

- Yes, steel pipes can be used for conveying sewage and wastewater. Steel pipes are known for their strength, durability, and resistance to corrosion, making them suitable for transporting various types of fluids, including sewage and wastewater. Additionally, steel pipes can withstand high pressure and are capable of handling the abrasive and corrosive nature of sewage and wastewater, making them a reliable choice for such applications.

- Q: How are steel pipes protected during transportation and storage?

- Steel pipes are typically protected during transportation and storage through various measures such as corrosion prevention coatings, wrapping them with protective materials like plastic or rubber, and securing them properly to prevent any damage or movement.

- Q: How are steel pipes used in industrial manufacturing processes?

- Steel pipes are commonly used in industrial manufacturing processes for various purposes such as transporting fluids, gases, and solids, as well as providing structural support. They are used in industries like oil and gas, construction, automotive, and chemical manufacturing. Steel pipes offer high durability, strength, and resistance to corrosion, making them ideal for handling harsh environments and high-pressure applications. Additionally, they can be easily welded, bent, and manipulated to fit specific requirements, allowing for efficient and cost-effective installations.

- Q: Can steel pipes be used for mining applications?

- Indeed, mining applications do permit the utilization of steel pipes. The mining industry frequently employs steel pipes for diverse objectives. Specifically, they are commonly utilized for the conveyance of fluids, such as water or slurry, during mining operations. Steel pipes possess remarkable attributes, including durability, strength, and resistance to corrosion, rendering them suitable for the demanding and corrosive underground mining environments. They have the ability to endure high pressure and effectively manage the substantial loads associated with mining applications. Furthermore, the ease with which steel pipes can be welded and connected facilitates efficient installation and maintenance. Considering all factors, steel pipes prove to be a reliable and economically sound option for mining applications.

- Q: What is the role of steel pipes in the renewable energy sector?

- Steel pipes play a crucial role in the renewable energy sector as they are commonly used for transporting various fluids, including water, steam, and gases, in renewable energy systems. They are extensively utilized in the construction of wind turbines, solar power plants, and geothermal installations. Steel pipes are employed for the transportation of water in hydroelectric power plants and for the transmission of heat in concentrated solar power systems. Additionally, they are instrumental in the distribution and storage of fuels such as hydrogen and biogas, which are vital components of renewable energy technologies. Overall, steel pipes provide a reliable and durable means of transporting resources and energy within the renewable energy sector.

- Q: What is the maximum allowable pressure for steel pipes?

- The maximum allowable pressure for steel pipes typically depends on various factors such as the pipe's diameter, thickness, and material grade. Additionally, it is crucial to consider the intended application and the specific industry standards or codes being followed. Therefore, there is no universal answer to this question, as the maximum allowable pressure can vary significantly depending on these factors. It is essential to consult relevant codes and standards specific to the application to determine the appropriate maximum allowable pressure for steel pipes.

- Q: Can steel pipes be used for electrical conduit systems?

- Yes, steel pipes can be used for electrical conduit systems. Steel pipes are a popular choice for electrical conduit systems due to their durability and strength. They are capable of providing protection to electrical wires and cables from physical damage, moisture, and other environmental factors. Steel pipes also have high resistance to fire, making them suitable for installations in buildings where fire safety is a concern. However, it is important to note that steel pipes may require proper grounding to prevent electrical shocks and should comply with local building and electrical codes.

- Q: Can steel pipes be used for underground water supply pipelines?

- Indeed, underground water supply pipelines can utilize steel pipes. The reason for the widespread use of steel pipes in water supply systems is their ability to endure, their strength, and their resistance to corrosion. They can withstand high levels of pressure and can accommodate large quantities of water. Furthermore, steel pipes come in a variety of sizes and thicknesses, granting flexibility in the design and installation of underground water supply pipelines. However, it is crucial to ensure that the steel pipes are appropriately coated or lined to avert corrosion and uphold the water's quality during transportation. Regular inspections and maintenance must also be carried out to prevent any potential problems with the steel pipes.

- Q: Can steel pipes be used for piling?

- Yes, steel pipes can be used for piling. Steel pipes are commonly used in piling applications due to their strength, durability, and versatility. They are able to withstand the load and pressure of the soil and provide a stable foundation for structures. Steel pipes used for piling are typically driven into the ground using specialized equipment, ensuring they are securely positioned. Additionally, steel pipes can be easily cut and welded to the required length, making them suitable for various piling projects.

- Q: How are steel pipes used in underground drainage systems?

- Steel pipes are commonly used in underground drainage systems due to their durability and strength. They are used to transport wastewater, stormwater, and other liquids away from buildings and infrastructure to a designated discharge point. The steel pipes provide a reliable and long-lasting solution, ensuring the efficient flow of water and preventing any potential leaks or damage to the surrounding environment.

Send your message to us

Seamless Black Carbon Steel Pipe Of API 5L

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords