Aslcoa Aluminum Coil 8011 Ho for Wine / Medicine PP Cap

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of 8011 HO Aluminum Coil for Wine / Medicine PP Cap

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of 8011 HO Aluminum Coil for Wine / Medicine PP Cap

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of 8011 HO Aluminum Coil for Wine / Medicine PP Cap

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

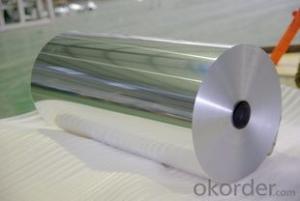

5. Image of 8011 HO Aluminum Coil for Wine / Medicine PP Cap

6. Package and shipping of 8011 HO Aluminum Coil for Wine / Medicine PP Cap

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How much fluorocarbon and polyester paint should be used in production of aluminum coil and aluminum-plastic panel?

- The theoretical calculation is very complicated and far from actual result. In general, the manufacturer knows how much area and how thick their products can be painted.

- Q: How are aluminum coils inspected for defects?

- Aluminum coils are inspected for defects through various methods such as visual inspection, ultrasonic testing, eddy current testing, and X-ray inspection. These techniques help identify surface imperfections, cracks, porosity, and other defects that may affect the quality and integrity of the coils.

- Q: Describe the various uses of aluminum coils in the manufacturing industry.

- <p>Aluminum coils are widely used in manufacturing due to their lightweight, corrosion resistance, and strength. They are utilized in the production of various products such as automotive parts, aerospace components, and construction materials. Aluminum coils are also employed in the manufacturing of electrical wiring, heat exchangers, and packaging materials. Additionally, they are used in the production of cans and foils for food and beverage industries. Their versatility makes aluminum coils an essential material in many manufacturing processes.</p>

- Q: Are aluminum coils suitable for signage systems?

- Yes, aluminum coils are highly suitable for signage systems. They are lightweight, durable, and weather-resistant, making them ideal for both indoor and outdoor signage. Aluminum coils can be easily shaped and molded into various designs and sizes, providing flexibility in creating custom signage solutions. Additionally, aluminum coils offer excellent corrosion resistance and can withstand harsh environmental conditions, ensuring long-lasting and visually appealing signage.

- Q: Can aluminum coils be used in the production of transportation vehicles?

- Yes, aluminum coils can be used in the production of transportation vehicles. Aluminum is a lightweight and corrosion-resistant material, making it a popular choice in the automotive industry. Its high strength-to-weight ratio helps improve fuel efficiency, reduce emissions, and increase overall vehicle performance. Aluminum coils can be used to manufacture various components of transportation vehicles such as body panels, frames, chassis, and suspension parts. Additionally, aluminum's recyclability makes it environmentally friendly and contributes to the sustainability of the transportation industry.

- Q: What are the different surface treatments applied to aluminum coils?

- Some common surface treatments applied to aluminum coils include anodizing, painting, and laminating. Anodizing involves creating a protective oxide layer on the surface of the aluminum, which improves its corrosion resistance and durability. Painting can be done using various techniques such as coil coating or spray painting, providing aesthetic appeal and additional protection. Laminating involves bonding a protective film or coating onto the aluminum surface, enhancing its resistance to scratches, abrasion, and chemicals.

- Q: Are aluminum coils susceptible to warping or bending?

- Yes, aluminum coils are susceptible to warping or bending. Aluminum, although lightweight and highly corrosion-resistant, is a relatively soft metal compared to other materials like steel. This means that it is more prone to bending or warping under certain conditions. Factors such as excessive heat, heavy loads, or improper handling can cause aluminum coils to deform. It is important to handle and store aluminum coils carefully to prevent any damage or distortion. Additionally, proper installation techniques and maintenance practices can help minimize the risk of warping or bending.

- Q: How are aluminum coils annealed?

- Aluminum coils are typically annealed through a process known as heat treatment. This involves heating the coils to a specific temperature and then slowly cooling them down. The purpose of annealing is to soften the aluminum and improve its ductility, making it easier to work with. The first step in annealing aluminum coils is to clean them thoroughly to remove any contaminants. The coils are then placed in a furnace, which is heated to the desired temperature. The temperature and duration of the annealing process depend on the specific grade and thickness of the aluminum being treated. Once the coils reach the desired temperature, they are held at that temperature for a predetermined amount of time. This allows for the internal structure of the aluminum to become more uniform and relieves any internal stresses that may have developed during the manufacturing process. After the annealing process is complete, the coils are slowly cooled down in the furnace. This slow cooling is important to prevent the formation of any new internal stresses. Once the coils have cooled to room temperature, they are ready for further processing or use. In some cases, a process known as quenching may be used after annealing. Quenching involves rapidly cooling the aluminum by immersing it in a quenching medium, such as water or oil. This can help to further improve the mechanical properties of the aluminum, such as its strength and hardness. Overall, the annealing process for aluminum coils is a carefully controlled heat treatment that aims to improve the metal's properties and make it more suitable for various applications.

- Q: How are aluminum coils protected against scratching?

- Aluminum coils are typically protected against scratching through various methods such as applying a protective film or coating, using protective packaging materials, or employing proper handling and storage procedures to minimize contact with abrasive surfaces.

- Q: This question asks about the distinctions among various grades of aluminum coils, likely referring to their properties and uses.

- <p>Aluminum coils are differentiated by grades based on their alloy composition, thickness, and specific applications. Common grades include 1000 series (99% pure aluminum, soft and malleable), 3000 series (aluminum-manganese alloys, good for cooking utensils), 5000 series (aluminum-magnesium alloys, used in marine applications), and 6000 series (aluminum-magnesium-silicate alloys, known for strength and used in construction). Each grade has distinct properties such as strength, formability, and corrosion resistance, which determine their suitability for different industries and applications.</p>

Send your message to us

Aslcoa Aluminum Coil 8011 Ho for Wine / Medicine PP Cap

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords