API Seamless Steel Pipes from large Group

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless Pipe ASTM A106/53:

carbon seamless steel pipes are widely used in gas, water and oil, transpotation;constructions;Bridge,highway,windows of model steel door; building materials;fences;heating facilities Fluid Pipe;conduit pipe,scaffolding pipe.etc.

Payment Terms: L/C D/A D/P T/T

Packing and shipment

Packaged in bundles,as per customers' requirements, it can also bepackagesd as beveled ends, typed marking, black painting, plastic caps protection,woven bags packing

For 20" container the max length is 5.8m; For 40" container the max length is 12m. other options are available based on customer requests. Please discuss when placing orders.

Standard: GB/T8162-2008; GB/T8163-2008; GB3087-2008; GB5310-2008; GB9948-2006; ASTM A106/A53 GR.B; API 5L GR.B

Application: Fluid pipes, structural pipes, oil and gas pipes

Packaging: bare/paint, bevelled ends, caps

Material: 20#, Q345B (16Mn)

Outside diameter: 89mm-820mm

Wall thickenss: 4mm-45mm

2、Main Features of the Seamless Pipe ASTM A106/53:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Pipe ASTM A106/53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

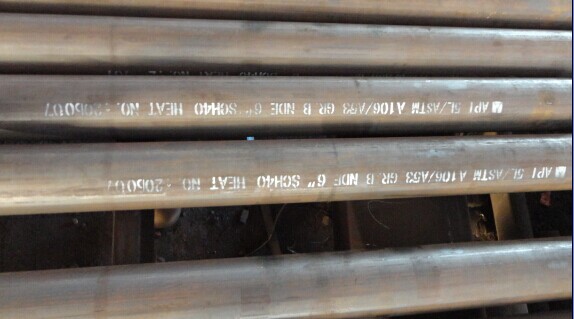

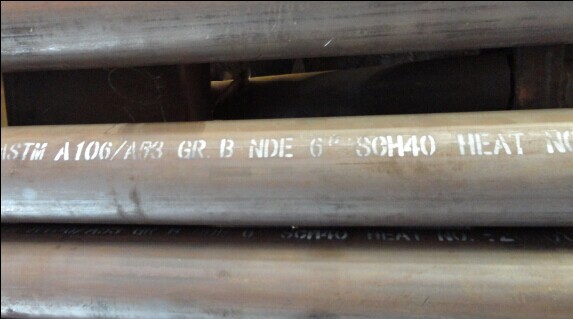

6、Seamless Pipe ASTM A106/53 Images:

- Q: Can steel pipes be galvanized?

- Yes, steel pipes can be galvanized.

- Q: Are steel pipes resistant to corrosion?

- Yes, steel pipes are generally resistant to corrosion due to the protective layer of oxide that forms on their surface, but their resistance can vary depending on the specific grade of steel and the environment they are exposed to.

- Q: What are the different methods of pipe threading for steel pipes?

- There are several methods of pipe threading for steel pipes, including manual threading, machine threading, and roll grooving. Manual threading involves using a hand-held die and a pipe vise to create threads on the pipe. Machine threading uses power-driven threading machines that can quickly and accurately create threads on steel pipes. Roll grooving, on the other hand, involves using a specialized machine that forms a groove on the pipe, eliminating the need for threading and allowing for easy installation of pipe couplings or fittings. Each method has its advantages and is chosen based on factors such as pipe size, project requirements, and efficiency.

- Q: How are steel pipes insulated to prevent freezing?

- Steel pipes are commonly insulated to prevent freezing by applying a layer of insulation materials, such as foam or fiberglass, around the pipes. This insulation helps to maintain the temperature of the pipes and prevents heat loss, thus preventing the water inside from freezing during cold weather conditions. Additionally, heat tracing cables can be used along with the insulation to provide an extra layer of protection by supplying heat to the pipes.

- Q: Can steel pipes be used for conveying solids?

- Yes, steel pipes can be used for conveying solids. Steel pipes are known for their high strength and durability, making them suitable for transporting various solid materials such as ores, coal, grains, and minerals. The smooth interior surface of steel pipes allows for efficient and smooth flow of solids, ensuring effective conveyance over long distances.

- Q: What are the uses of welded steel pipes?

- The spiral submerged arc welded pipe (SY5036-83) for the delivery of pressurized fluid is made of hot rolled steel strips for tube billets, often spirally formed, welded by double submerged arc welding and used for the transmission of pressurized fluid. The steel pipe has strong pressure bearing ability and good welding performance. After a rigorous scientific examination and test, it can be used safely. The utility model has the advantages of large caliber of the steel pipe, high transmission efficiency, and investment in laying pipelines. Mainly used in the transportation of petroleum and natural gas pipelines.

- Q: How are steel pipes used in the construction of nuclear power plants?

- Steel pipes are used in the construction of nuclear power plants for various purposes, including transporting coolant, steam, and gases, as well as providing structural support for the overall system. These pipes are specifically designed to withstand high pressures, extreme temperatures, and corrosive environments, ensuring the safe and efficient operation of the nuclear power plant.

- Q: What are the different standards for steel pipes?

- There are several different standards for steel pipes, including ASTM (American Society for Testing and Materials), API (American Petroleum Institute), and ASME (American Society of Mechanical Engineers). These standards specify the requirements for various aspects of steel pipes, such as their dimensions, chemical composition, mechanical properties, and testing procedures. These standards ensure that steel pipes meet the necessary quality and safety standards for their intended applications.

- Q: What are the common methods for inspecting the condition of steel pipes?

- There are several common methods for inspecting the condition of steel pipes. These methods aim to identify any defects or potential issues that could affect the integrity of the pipes. 1. Visual Inspection: This involves a thorough visual examination of the pipes to identify any visible signs of damage such as corrosion, cracks, or leaks. Inspectors may use tools such as flashlights, mirrors, or borescopes to access hard-to-reach areas. 2. Ultrasonic Testing: This method uses high-frequency sound waves to detect defects within the steel pipes. A transducer is used to emit sound waves, and any disruptions or reflections in the waves can indicate potential issues such as cracks or thinning of the pipe walls. 3. Magnetic Particle Testing: This technique is primarily used to detect surface cracks or defects in steel pipes. A magnetic field is applied to the pipe, and fine iron particles are then applied to the surface. The particles will gather at any areas where there are surface defects, making them easily visible. 4. Eddy Current Testing: This non-destructive testing method is used to detect surface and near-surface defects in steel pipes. It involves passing an alternating current through a coil, which induces eddy currents in the pipe. Any disruptions or changes in the eddy currents can indicate defects such as corrosion or cracks. 5. Radiographic Testing: This method uses X-rays or gamma rays to inspect the internal structure of steel pipes. X-ray film or a digital detector is placed on one side of the pipe, while the X-ray source is placed on the other side. The rays penetrate the steel, and any irregularities or defects can be identified on the film or through digital imaging. 6. Dye Penetrant Inspection: This technique is used to detect surface-breaking defects in steel pipes. A dye penetrant is applied to the surface of the pipe, and after a specified period, a developer is used to draw out the dye from any defects. The dye will make the defects easily visible. These methods, either individually or in combination, provide a comprehensive inspection of steel pipes, ensuring their reliability and safety in various industries such as oil and gas, construction, and manufacturing.

- Q: How are steel pipes used in bridge construction?

- Steel pipes are commonly used in bridge construction as piling or foundation elements. They are driven into the ground to provide support and stability to the bridge structure. Additionally, steel pipes can be used as structural members in the bridge's superstructure, such as for the construction of bridge piers or trusses, due to their high strength and durability.

Send your message to us

API Seamless Steel Pipes from large Group

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords