Anti-UV Waterproof Co-extrusion Indoor WPC Floor Wood Plastic Composite Passed CE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Features of the WPC Decking:

1. Recyclable, Eco-friendly, saving forest resources

2. With the look of the natural wood, but less timber problems

3. Moisture/water resistant, less rotten, proven under salt water condition

4. Barefoot friendly, anti-slip, less cracking, less warping

5. Requires no painting, no glue, low maintenance effort

6. Weather resistant, suitable from minus - 40 to 60 centigrade degree

7. Termites and insects resistant, and moldy-proof

8. Easy to install and clean

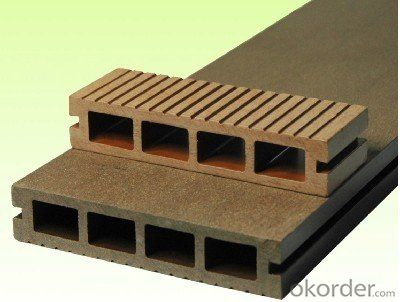

Specification of the WPC Decking:

component | 30%HDPE(Grade A Recycled HDPE) 60%bamboo/wood fiber component 10%chemical additives New material capped outside |

Size | 140X20mm |

Design | Solid decking |

Length | 2.9m/pc standard length, also from your required |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE,Walnut,graystone,Cedar,Rosewood) and we can adjust the new color according to the order requirement |

Cerfiticate | ISO9001, ISO14001, CE, FSC Certificate,"REACH"Test Reports by SGS; Intertek Test Report by ASTM standard..etc. |

Images of Co-extrusion WPC Decking:

FAQ of Co-extrusion WPC Decking :

1. Available Colours?

5 regular colors to choose ( IPE,Walnut,graystone,Cedar,Rosewood )

2. How to Install?

3.Treatment for Option

- Q: Can tile flooring be on the floor?

- Is the best, but also the best of the construction of the wooden floor of the construction of the mining of the matter, because the ground after the tile is the most flat, and now there are a lot of people in Europe there Do it, we just want to save the cost did not do so, you have to do this has reached the European standards,

- Q: Composite wood flooring

- Composite wood flooring with solid wood flooring and laminate flooring, solid wood flooring is divided into three layers of solid wood flooring and multi-layer parquet.

- Q: What is the padded floor under the composite floor?

- Yes, the floor is to first level leveling, and then shop that the moisture-proof membrane at the bottom, and then in the above floor

- Q: There are several types of composite flooring

- First, the composite floor by wood composite floor and laminate flooring. Among them, the solid wood composite floor is divided into three layers of solid wood flooring and multi-layer parquet, the wooden floor has gradually become the majority of customers of the consumer. Second, solid wood flooring and solid wood flooring are made of natural materials from the production, so in some natural properties have a lot in common, such as both have a natural texture, comfortable foot feeling, Dongnuanxialiang and so on. However, they have some different places, solid wood flooring than the solid wood flooring in the installation and maintenance requirements are relatively simple, and the price is much cheaper than the solid wood flooring. Third, strengthen the composite floor, including wear-resistant layer, decorative layer, substrate layer and balance layer. Strengthen the composite floor style variety, and affordable, and easy to clean and clean. Therefore, the choice of strengthening the composite flooring groups also accounted for a large part. However, to strengthen the composite floor is the most critical to choose environmentally friendly flooring products. Want to know whether the environmental protection on the floor, mainly to see if there is no national certification of environmental protection certificate. Also see whether the enterprise is a professional manufacturer of wood flooring, so that the quality of the floor can be guaranteed.

- Q: Solid wood flooring must use solid wood baseboard?

- No one is required to be solid wood foot line, pvc can, that is, the provision of the skin can be transferred Jiu Xue snow effect is not good, the color is very poor, if the solid wood foot line, the color and the door is similar, so the overall effect is particularly good

- Q: My family intends to lay the composite floor, but the designer said the best shop before the shop and the ridge, suspected he wanted to earn more money, there is no teacher 窢 Fan promotion both 讵 rejuvenation Leakai guidance Oh, thank you more

- Solid wood flooring generally have two kinds of options is a choice with the Dragon is a choice without the Dragon This choice according to your home to choose the case if not with the dragon laying the floor pipe and pipe in the ground to slot Deep buried

- Q: What is the difference between composite flooring and tiles?

- To the occasion, the general bedroom and study more suitable for wood flooring. The kitchen, the bathroom is more suitable for tiles. One: tiles: tiles are often said floor tiles. Tiles are cheap, and easy to clean and clean, tiles are also wear-resistant. However, the tiles of the foot feel and decorative effect as wooden floor. Second: wood flooring: wood flooring is divided into solid wood flooring, parquet. 1) solid wood flooring: solid wood flooring is very healthy, environmental protection, decoration effect is good. In the price is more expensive, and not easy to install and maintain, need regular waxing. 2) parquet: solid wood flooring changed the previous physical structure, better stability. In the price, than the solid wood flooring to be cheaper, are middle consumer products. Is the home decoration in the more popular a class of ground decoration materials. 3) to strengthen the floor: to strengthen the floor is the biggest feature of wear resistance is good, very suitable for living room and other places more concentrated, is the wood floor varieties in the cheapest floor, is the working class people first floor decoration materials. However, in the installation and maintenance is very simple.

- Q: I have purchased all the wood and am having a guy install my wood floor. I've purchased a good adhesive to get the floor to adhere to the concrete underneath. Now I am wondering if I need a glue to slather into the tongue and groove joints? Your thoughts?

- If you have the proper glue to adhere the engineered wood to slab you most definitely do not need any glue for the tongue and groove. You only need the special sized / shaped trowel. Gluing the t/g together is only done when creating a floating floor system from engineered wood. Any questions you can e mail me through my avatar. GL

- Q: Home underground water pipes leaking, to the composite floor valve crisp Juyi wrong with nitrogen hair open repair, the floor is a card slot, not very good demolition, but also afraid to break the floor, and ask how to open better The (To open the location is in the bathroom door 40cm place) Question added: I would like to split from the room at the stalls try, their own should pay attention to what? More

- I suggest you find a professional pavement to remove, because the composite floor card slot, their handling is not good, it is best to find a professional to get, the other soaked in the floor after the demolition of the valve crisp Juyi wrong And then cool place to dry and then pavement, hoping to help you

- Q: Because it is a newly renovated house has not moved Dinghu guilty cunning Chong twisted anchor into the floor flooding degree is relatively large, the water leaked 2 days to find the water seepage downstairs walls, paint are blasting Please come after the sale Treatment is to dig out the most serious part of the flooding, the rest do not deal with such water vapor their own volatile I would like to ask those who do not need to replace those soaked in the future will not mold mold, smell out of the problem added: Smell it? Plastic film must have been soaked, is not going to penetrate into the floor inside? More

- Has just dealt with a number of questions on the quality of the floor of the elephant. Out of the question to find Consumers Association corresponders on their fear, Ding Hu Gui guilty cunning attack or even this sentence, buy the floor to go to Beac, Buy multiple layers.

Send your message to us

Anti-UV Waterproof Co-extrusion Indoor WPC Floor Wood Plastic Composite Passed CE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords