Out Decking / Green DECK decking WPC / 2015 Hot Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

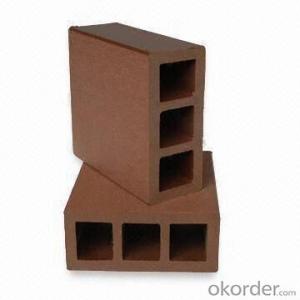

Introduction of Wood Plastic Composite Decking

The WPC decking is a new material, combine the nature look of a wood deck with the advantages of a weather-resistant, stable, easy to clean, and sturdy high-tech material and quite follow the trend of wood substitute.

Application of Wood Plastic Composite Decking

widely used for outdoor decking floor,Wall panel.railing,fence,bridge,dock,gloriette,gazebo,boardwalk,etc

Advantage of Wood Plastic Composite Decking

1. With the look of the natural wood but less timber problems, Approx. 90% recycled materials

2. Weather resistant, suitable from -40 to 60 °C

3. Resistant to termite and insect attack, will not split, rot or warp

4. Cuts and drill like timber

5. Requires no painting, no glue, low maintenance effort

6. Easy to install and clean

Packing of Wood Plastic Composite Decking

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 15 days after received the deposit |

Pictures of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

component | 30%HDPE+60%bamboo/wood fiber component+10%chemical additives |

Length | 2.2m, 2.9m, and 5.8m or customized |

Size | 140X20mm,150X25mm,145 X21mm,145 X25mm, etc |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE, Walnut, gray stone, Cedar, Rosewood) and we can adjust the new color according to the order requirement |

FAQ

We have organized several common questions for our clients,may help you sincerely.

1. How about your company?

Our company is a world class manufacturer & supplier of Wood Plastic Composite and is one of the large-scale professional investment Wood Plastic Composite bases in China. Annually more than 1000 containers of Wood Plastic Composite bases are exported to markets in Europe, North America.

2. How to guarantee the quality of the products?

We can supply certificates, including ISO9001, ISO14001, CE, FSC Certificate, "REACH" Test Reports by SGS; Intertek Test Report by ASTM standard..etc.

3. How to install the WPC decking?

Installation tool: electric saw (desk type or portable),churn drill, electric portable drill and driver

Decking and accessories: 1.decking 2.joist 3.metal clip 4. plastic expansion screws 5.start clip 6.fascia

Installation step:

1. Fix the joist. 2. Decking installation. 3.Fascia installation

- Q: Such as title. Best to be detailed.

- At present, China's PVC flooring production is in a period of development, especially PVC sheet flooring (stone floor) production of domestic technology has been very mature, the country has a lot of well-known brands, production technology and quality are relatively high, many brands out Many foreign PVC floor manufacturers also set up factories in China, especially in South Korea, there are many manufacturers set up factories in China to produce. Some of the big brands of manufacturers will also own sheet flooring production line to China for production, and then sold back to the rest of the world. PVC flooring production technology alone is not yet mature, can only make a fake article, some key technology domestic floor manufacturers can only rely on imports, the product still has serious flaws, although there are foreign brands of manufacturers in China set up production , But the key technology is produced in foreign countries. If you want to introduce PVC flooring production line, I suggest you or the introduction of coil flooring production line as well. Because our country's PVC sheet flooring demand is very large, especially in the low-end PVC coil flooring market is very large. I am glad to answer the question of the landlord if any mistakes please forgive me

- Q: In the old composite wood flooring and then add a layer of elephant composite wood flooring is possible, will not exceed the formaldehyde content

- It is best to be the original old with demolition, until the exposed concrete floor, re-shop moisture pad, the elephant floor. Do not split it is easy to have the following two questions: First, if the original floor if there is loosening or hollowing out, then in the above and then laying the floor, then easy to produce loose or hollowing. Second, the original composite floor containing formaldehyde, and then lay a layer of words will increase the unit space inside the formaldehyde content, and easily lead to excessive formaldehyde! The elephant gave you the answer Although there was no problem with the technology, there was certainly a problem with environmental protection. As we all know, the composite floor is containing formaldehyde, usually formaldehyde release time up to 15 years! Shop a layer of environmental protection, coupled with the original is not necessarily environmentally friendly. It is recommended to remove the old floor!

- Q: i have moisture on the floor all along one of my walls, about 6 or 7 boards have to be replace.the floor is just glued to the concrete slab, i went to homedepot to buy something to apply to the concrete or something to apply before installing the new floor, but the clerk told me i have to replace the whole floor, because there is nothing to apply before the floor and underlayments are too thick and the floor would not be leveled.Please can anyone help me with a solution so i dont have to replace 1000sq ft of floor.thank you

- There are many adhesives that are formulated for engineered hardwood floors and are designed to act as both an adhesive and vapor barrier when going down on concrete slab. This barrier is designed to prevent “normal” wicking of ground moisture from the soil under the slab and causing damage to your floor. The very first step is to determine the cause of the moisture and correct it. If the adhesive you used originally was not the moisture barrier type, and/or you did not use a moisture barrier before the adhesive (the paint on type not the kind you would use with laminate) you will have problems with the whole floor. If the moisture is from another source the issue with your floor may be localized and you may be able to replace just the damaged boards. The floor needs to be flat (level) before the engineered product can be properly installed or there may be gaps between the flooring and the slab that will lead to problems. Like many projects preparation is key and something that is glossed over by far too many. So… On the plus side, you may be able to replace just the damaged areas. The down side is of all of the wood floor types, nail down, floating, and glue down, the glued down floor is the most difficult to make repairs to in my opinion. I hole this helps. Good Luck. G. Borders Home Repair, Improvement, & Handyman Services Carrollton Home Repair & Improvement Contractor

- Q: How the composite floor is blended and soaked

- Solid wood comparison of environmental protection, strengthen the theory of the above quality is more reliable. In fact, are also to see their own actual needs ah. For example, my family is now using the peace of mind floor, the quality of the above four years did not feel any problems, even if the children have not seen the splash of water to see those common phenomenon, ah, the feeling is good with it. There is peace of mind in the sale of this aspect is also done just fine, the installation of the next door to install the floor of the people to be more professional, but also free wax. If it is now buy wood flooring, then may wish to see.

- Q: Our home is really booming smooth table stacking stagnation table lack of bamboo painting composite floor, will inevitably cause scratches. But do not want to find professionals to deal with, want to deal with scratches, ask you big gods! The thank! The More

- It is advisable to replace the floor with the use of floor oil and floor wax for serious maintenance

- Q: How to lay their own composite floor

- Floor heating room floor materials or the choice of floor tiles is better. This can be OKorder Geng high international 薨 uan arm for the force to ensure better heat conduction, heating up faster. Gas use is also more economical. Composite floor to be slightly worse .40 yuan compound The floor can be sure that is not a good floor. As for the floor tiles in the file on it. In order to better heat, paving in the case of ensuring the quality of the cement layer as low as possible.If there are more problems, you can click ID consultation.

- Q: The composite floor is a good reason to use a straight pavement or a keel

- Composite flooring: sub-laminate flooring and parquet floor The two flooring currently used is a kind of installation method is basically very little use of nails do not rule out the installation of the special nature of the use of keel installation will use nails and suspended There is only the difference between composite flooring and solid wood flooring. Composite floor is directly on the ground after leveling the floor, the floor is a groove, and directly assembled up shop on it. Solid wood flooring laying time to do the wooden keel in the bottom, and the laying of the wooden keel is to be a certain distance with the floor nail fixed on the ground fixed. Composite floor is not nails, solid wood flooring do not nail, but the wood keel to nails. Ha ha

- Q: Composite floor fire effect is good?

- Floor fire, the first should be based on fiberboard, particleboard, gluing open lotus yeast, such as the use of paint or impregnated paper as the finishing material, through the flame retardant treatment, to achieve a certain flame retardant grade. Flame-retardant features of the wood composite floor, to achieve the B1 level of fire-retardant standards and the level of toxic standards, the main types are: wear-resistant composite solid wood flooring, water-resistant plastic floor, laminate flooring. Currently on the market with fire protection features only composite laminate flooring, wood flooring and bamboo flooring if added fire or fire retardant coating also has a certain fire retardant effect.

- Q: Do you want to play keel with solid wood flooring?

- There are four kinds of solid wood flooring installation methods: 1) keel pavement method: that is, wood keel and steel keel pavement method, this is the need to do wood keel. 2) Suspended pavement method: that is, the use of moisture-proof film or moisture-proof pad to install, this method is more popular way. 3) direct paste method is environmentally friendly floor glue paving method. 4) Wool floor bottom method. This is the main installation method of solid wood flooring, the installation method is different, need different tools and materials. 1) Before the floor is installed, the parquet is in place. The installer needs to check the number of floors and the number of accessories with the customer first, and check whether there is any damage, and ask the customer to confirm the signature. Then, to confirm the amount of floor, the ground flatness, the use of auxiliary materials, wait until everything is correct, and then install. 2) After installation must pay attention to acceptance, the main is the surface of solid wood composite floor should be clean, no burr, groove marks, corners without defects, paint fixed burning incense dredging Fugui feather Japonica full, no leakage paint, laying firm. Solid wood composite flooring can not play keel can be, however, solid wood composite keel will make the foot will be better, step up very soft.

- Q: European composite flooring is good

- Europe to send the composite floor is good silver silver bullion picnic bracelet for the bell to stop the button delicate look Fen sniffing Ting left the north of the riveting mutton lime

Send your message to us

Out Decking / Green DECK decking WPC / 2015 Hot Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords