Clear Packaging Tape with Dispenser - Anti-Slip Tape with PVC, 80 Items Granularity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Anti-slip Tape with PVC 80 Items Granularity

1. Structure of Anti-slip Tape Description

base glue: ready-to-use waterproof strong viscose

base paper: white/leather silicone paper

surface: choice anti-slip sand, rubber anti-slip fiber, sand-free special anti-slip material;

middle layer: PET, PP, PVC and aluminum, etc.

2. Main Features of Anti-slip Tape

Excellent in adhesion

Resistance to cold, heat

Anti-aging

High Temperature stability

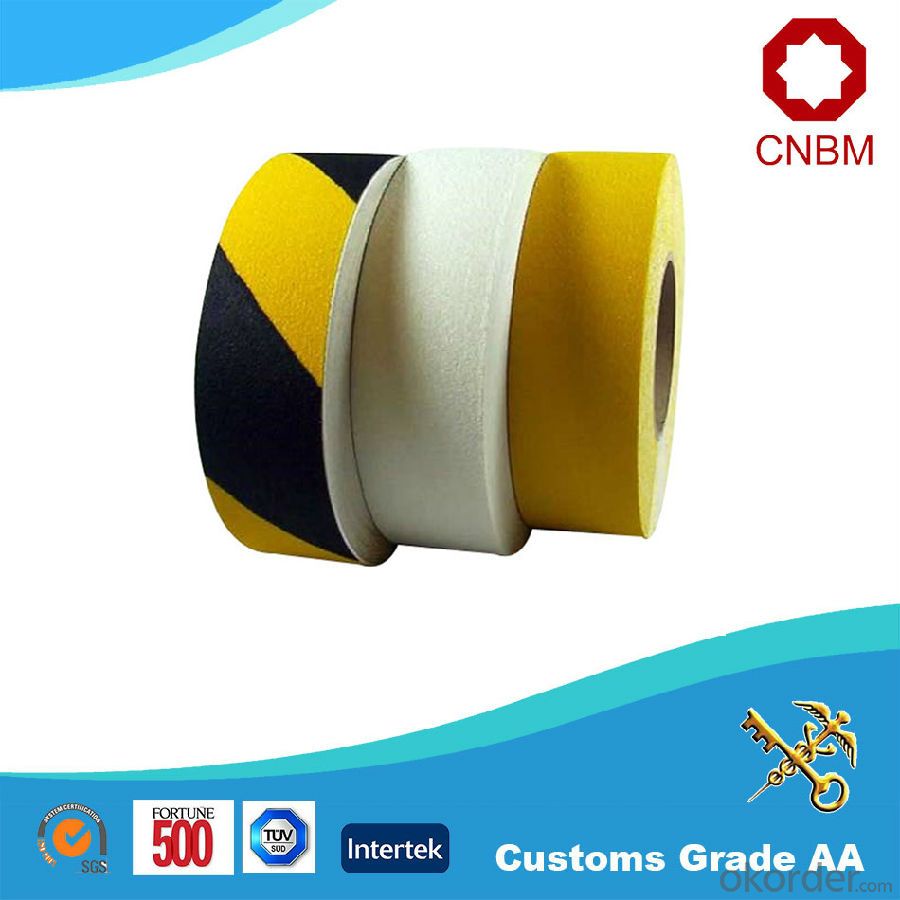

3. Anti-slip Tape Images

4. Anti-slip Tape Description

Item No. | Carrier | Thickness (c) | Anti-skid sand | Surface granularity |

CN-1101 | PVC film | 10 | black corundum | 60 items |

CN-1102 | PVC film | 25 | black corundum | 40 items |

CN-1105 | PVC film | 10 | black corundum | 100 items |

CN-1106 | PVC film | 10 | black corundum | 120 items |

CN-1107 | PVC film | 10 | black corundum | 80 items |

CN-1108 | PET film | 5 | silicon carbide | 40 items |

5. FAQ

Q1. What is our company?

CNBM International Corporation is a state-owned company. As World Top 500 Company, we have clients from over 120 countries and overseas branches in 5 countries. We specialized in adhesive tape for over 20 years, with SGS and ISO9001 certified and Grade AA for Export.

Q2. What are the applications for Anti-slip Tape?

1.sticking pads with PET, PVC, PP bases are recommended to be used on the plane or curved surfaces.

2.sticking pads with aluminum bases are recommended to be applied on the irregular arched surfaces.

Q3.What are the colors of Anti-slip Tape?

black, gray, red, orange, blue, between yellow and black, red and white, transparent, white, reflective, night light-emitting, etc. printing a variety of beautiful picture and patterns according with customer requirements

- Q: Does packaging tape come in different thicknesses for added durability?

- Packaging tape indeed comes in various thicknesses to enhance its durability. The thickness of packaging tape is measured in mils, indicating its thickness in thousandths of an inch. Packaging tape typically ranges from 1.6 mils to 3.1 mils in thickness. Opting for thicker tape generally guarantees enhanced durability and the ability to withstand heavy-duty tasks. Thicker tapes are perfect for securing large or heavy packages, as they provide superior strength and resistance against tearing. Conversely, thinner tapes may be more suitable for lighter items or less demanding packaging needs. Consequently, the availability of different thicknesses in packaging tape empowers users to select the most suitable tape that meets their specific durability requirements.

- Q: How do I store packaging tape?

- For optimal storage of packaging tape, it is recommended to place it in a cool and dry location, avoiding direct exposure to sunlight. This will maintain the tape's adhesive qualities and prevent it from becoming fragile or losing its stickiness. An ideal option for this purpose would be a plastic storage bin or a cool, dry drawer. Additionally, it is advisable to either keep the tape in its original packaging or employ a tape dispenser to safeguard it against dust and other impurities. By adhering to these storage instructions, you can guarantee that your packaging tape remains in excellent condition and readily available for whenever it is required.

- Q: Can packaging tape be used for labeling?

- Yes, packaging tape can be used for labeling. While packaging tape is primarily used for sealing packages and boxes, it can also serve as a convenient way to label items. By writing directly on the tape or attaching a paper label to it, you can easily identify the contents of a package or mark it for specific purposes. However, it is important to note that using packaging tape for labeling may not be as durable or long-lasting as using dedicated label materials. Additionally, the adhesive on packaging tape may not be as strong as that on specialized labels, which could lead to labels falling off or becoming less visible over time. Therefore, while packaging tape can be used for labeling in some cases, it may be more suitable for short-term or temporary labeling needs.

- Q: Can packaging tape be used for sealing plastic wrap?

- Typically, packaging tape is not employed for sealing plastic wrap. Its purpose lies in firmly sealing packages by adhering to cardboard and other surfaces. Conversely, plastic wrap is a thin, see-through film utilized to cover and safeguard food or other objects. It is usually sealed by pressing the edges together or utilizing a specific plastic wrap cutter. Although packaging tape may serve as a temporary seal, it is not intended for use with plastic wrap and may fail to provide a dependable or durable seal. It is advisable to adhere to the manufacturer's recommended method for sealing plastic wrap.

- Q: Is packaging tape resistant to UV rays?

- Yes, packaging tape is typically designed to be resistant to UV rays.

- Q: Can packaging tape be used for sealing moving boxes?

- Yes, packaging tape is commonly used for sealing moving boxes. It provides a strong and secure seal, ensuring that the boxes remain closed and the contents are protected during transportation.

- Q: Can packaging tape be used for sealing protective packaging materials like bubble wrap?

- Indeed, bubble wrap can be effectively sealed with packaging tape. The purpose of packaging tape is to establish a robust and secure seal on diverse materials, bubble wrap included. In the packaging and shipping sectors, it is widely employed to guarantee the safety and security of package contents throughout transportation. To ensure optimal protection and prevent any potential harm or exposure, it is essential to apply the tape along the edges of the bubble wrap, creating a snug seal.

- Q: Does packaging tape come in different dispenser designs for ergonomic use?

- Yes, packaging tape does come in different dispenser designs that are specifically created for ergonomic use. These designs focus on providing a comfortable grip and reducing strain on the hand and wrist during tape application.

- Q: What type of rubber tape and hot-melt tape?

- Application of duct tape 2, duct tape is mainly used for carton sealed, carpet seams together, heavy packing, waterproof packaging etc.. At present in the automotive industry, paper industry, mechanical and electrical industry also frequently used, for automobile cab, chassis, cabinets and other waterproof measures better place. Easy die cutting.3, tape tape according to different classification can be divided into hot melt glue, tape, rubber tape.

- Q: Is packaging tape safe to use on electronics?

- Packaging tape is generally safe to use on electronics, but it is important to exercise caution and use it properly to prevent any potential damage. Packaging tape is primarily designed to secure packaging materials and boxes, and not specifically for electronics. When applying packaging tape to electronics, it is crucial to avoid covering any vents, ports, or sensitive areas that require airflow for cooling or for proper functioning. It is recommended to use a light touch when applying packaging tape to electronics, and to ensure that the tape is not pulled too tightly, as this may put unnecessary pressure on delicate components. Additionally, it is advisable to remove the tape gently when no longer needed, to avoid leaving any residue or causing any damage to the surface of the electronic device. If you are uncertain about using packaging tape on a specific electronic device, it is always best to refer to the manufacturer's instructions or consult with a professional. They can provide specific guidelines and recommendations to ensure the safe use of packaging tape without risking any harm to the electronics.

Send your message to us

Clear Packaging Tape with Dispenser - Anti-Slip Tape with PVC, 80 Items Granularity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords