2 Packaging Tape 50 - Anti-Slip Tape with White/Leather Silicone Paper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Anti-slip Tape with White/Leather Silicone Paper

1. Structure of Anti-slip Tape Description

base paper: white/leather silicone paper

surface: choice anti-slip sand, rubber anti-slip fiber, sand-free special anti-slip material;

middle layer: PET, PP, PVC and aluminum, etc.

base glue: ready-to-use waterproof strong viscose

2. Main Features of Anti-slip Tape

Excellent in adhesion

Resistance to cold, heat

High Temperature stability

High Temperature stability

High mechanical strength

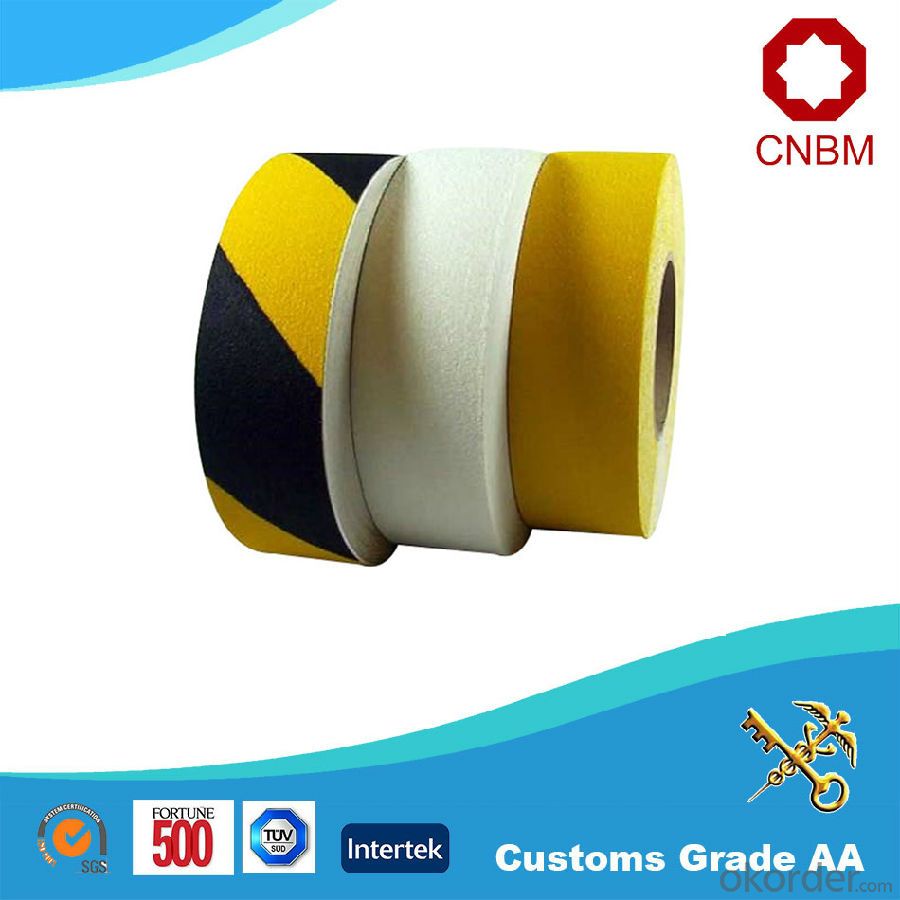

3. Anti-slip Tape Images

4. Anti-slip Tape Description

Item No. | Carrier | Thickness (c) | Anti-skid sand | Surface granularity |

CN-1101 | PVC film | 10 | black corundum | 60 items |

CN-1102 | PVC film | 25 | black corundum | 40 items |

CN-1105 | PVC film | 10 | black corundum | 100 items |

CN-1106 | PVC film | 10 | black corundum | 120 items |

CN-1107 | PP film | 5.4 | black corundum | 70 items |

CN-1108 | PET film | 5 | silicon carbide | 40 items |

5. FAQ

Q1. What can we do for you?

24 hours service for you

Professional consultation on your local market

Custom-made advices for your need

Your inquiry will be replied within 12 hours.

Satisfactory sales service

Q2.What are the colors of Anti-slip Tape?

black, gray, red, orange, blue, between yellow and black, red and white, transparent, white, reflective, night light-emitting, etc. printing a variety of beautiful picture and patterns according with customer requirements

Q3. What are the applications for Anti-slip Tape?

1.sticking pads with PET, PVC, PP bases are recommended to be used on the plane or curved surfaces.

2.sticking pads with aluminum bases are recommended to be applied on the irregular arched surfaces.

- Q: Can scotch tape wrap wires?

- Their staff specially explained that they could not go to wrap wires and the like, and the transparent tape contained thick colloid and had the effect of electrifying

- Q: Can packaging tape be used for sealing plastic tubing?

- Packaging tape has the capability to seal plastic tubing. Its design ensures a robust and reliable seal on different surfaces, including plastic materials. Nonetheless, it is crucial to take into account the particular purpose and demands of the plastic tubing. In instances where the tubing is intended for containing pressurized liquids or gases, or if it necessitates a long-lasting and resilient seal, specialized techniques like heat sealing or specific adhesives formulated for plastic materials might be more suitable. Ultimately, the appropriateness of packaging tape for sealing plastic tubing relies on the specific situation and requirements of the application.

- Q: Can packaging tape be used for sealing plastic wrap?

- Typically, packaging tape is not employed for sealing plastic wrap. Its purpose lies in firmly sealing packages by adhering to cardboard and other surfaces. Conversely, plastic wrap is a thin, see-through film utilized to cover and safeguard food or other objects. It is usually sealed by pressing the edges together or utilizing a specific plastic wrap cutter. Although packaging tape may serve as a temporary seal, it is not intended for use with plastic wrap and may fail to provide a dependable or durable seal. It is advisable to adhere to the manufacturer's recommended method for sealing plastic wrap.

- Q: Can packaging tape be used for sealing glass jars?

- Yes, packaging tape can be used for sealing glass jars. It provides a strong and secure seal, ensuring the contents remain fresh and protected. However, it is important to note that specialized jar sealants or methods, such as canning lids or rubber seals, may be more suitable for long-term storage or preserving purposes.

- Q: Can packaging tape be used for sealing wooden crates?

- Sealing wooden crates can indeed be accomplished with packaging tape, which creates a sturdy and reliable bond. This ensures that the crate remains tightly sealed throughout transportation or storage. Packaging tape is specifically designed to adhere well to different surfaces, including wood, making it an excellent option for sealing wooden crates. Nevertheless, it's crucial to take into account the weight and dimensions of the crate before solely depending on packaging tape. In the case of heavier or larger crates, reinforcing the seal with supplementary methods like nails or screws may be necessary.

- Q: Can packaging tape be used for sealing plastic storage jars?

- Yes, packaging tape can be used for sealing plastic storage jars. Packaging tape is designed to provide a strong and secure seal, making it suitable for various applications including sealing plastic storage jars. It can effectively keep the contents of the jar protected and prevent any leakage or contamination. However, it is worth noting that there are other options specifically designed for sealing jars, such as jar lids and seals, which may provide a more secure and airtight seal.

- Q: Is packaging tape safe for use on painted surfaces or walls?

- Packaging tape is generally considered safe when used on painted surfaces or walls. However, it is crucial to exercise caution and employ proper techniques to minimize the risk of potential damage. To ensure that the tape does not peel off or harm the paint, it is advisable to first test a small, inconspicuous area before applying it. Moreover, it is recommended to remove the tape gently and slowly to avoid any paint peeling or residue. In cases where the paint is delicate or the tape has been left on for a prolonged period, there is a slight possibility of minor damage such as slight paint discoloration or removal. Therefore, it is always wise to handle packaging tape with care and take necessary precautions to safeguard the painted surfaces or walls.

- Q: Does packaging tape come in different thicknesses?

- Yes, packaging tape does come in different thicknesses. Packaging tape is available in a variety of thicknesses to accommodate different needs and requirements. Thicker tapes are typically more durable and are suitable for heavy-duty applications where extra strength and resistance are necessary. On the other hand, thinner tapes are often used for lighter packages or general everyday use. The choice of thickness depends on the weight and size of the package being secured, as well as the level of reinforcement desired.

- Q: Can packaging tape be used for sealing electrical or wiring components?

- Using packaging tape for sealing electrical or wiring components is not recommended. Packaging tape is not designed to insulate or protect against electrical currents. It does not possess the necessary properties required for ensuring the safety and reliability of electrical connections. Therefore, it is crucial to utilize suitable electrical tape or other specialized materials that are specifically created for sealing and insulating electrical components.

- Q: Can packaging tape be used for sealing plastic storage bags?

- Yes, packaging tape can be used for sealing plastic storage bags. It provides a strong adhesive bond that helps keep the bags securely sealed.

Send your message to us

2 Packaging Tape 50 - Anti-Slip Tape with White/Leather Silicone Paper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords