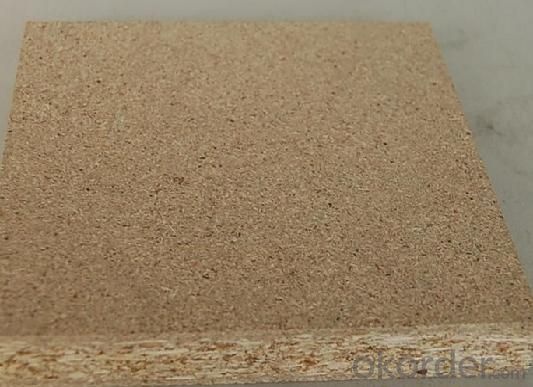

Anti-Moisture Particle Board Moisture Resistant Chipboard

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Size: 1220*2440mm/1830*3660mm and as your requirement

Core: Poplar, Hardwood, Hardwood, Combi, Birch, eucalyptus, as your requirement.

Thickness: 9mm to 25mm and as for your requirement

Application:

1) Flooring cores---Particle boards of engineering grade are suitable as the core board of variable decorative materials.

2) Counter-tops--- as core boards for counter tops

3) Particle board underlay for flooring.

4) Housing deals

5) Stair steps—PB steps have even thickness, with bull nose on side, makes installation easy and fast.

6) Shelf board

7) Door core, door frame, and shaped parts

b. water-resistant particle boards

A fixed proportion of damp-proof particle was added to the manufacture of water-resistant particle boards, thus dramatically reducing its swelling rate by contact with water. After soaked in the water for 24 hours, the swelling rate is 6%-10% only.

Major applications for water-resistant particle board:

Kitchen cabinet---- with enhanced anti-damp ability, water-resistant particle boards are perfect for making shelves, side boards, back boards, drawer, doors, etc.

Pictures:

Features

1) Environmental friendly, E1,E0,super E0 , FSC compatible

2) World-leading equipment to ensure premium quality products

3) Fine physical performance

4) Elegant color with smooth surface and pure texture, perfect for basis materials.

5) High-availability large-sheet basis.

6) Variable product for different market segments according to customer’s demands.

FAQ: A: What is your packing?

Q: Pallets(80mm) covered with plywood or carton and then steel for strength.

- Q: Some of advantages of particleboard

- the internal cross-scattered structure of the granular, the direction of the performance of the same basic, transverse bearing capacity is good;

- Q: What create an excellent condition.

- Many furniture manufacturers have re-use of particleboard as raw materials, in addition, directional particleboard is also gradually accepted by consumers

- Q: Today's demand for wood-based panel products

- which gave the development of China's particleboard industry opportunities The Therefore, China's particleboard consumption is expected to increase year by year.

- Q: According to the surface conditions:

- decorative particleboard: impregnated paper finishes particleboard; decorative laminate veneer particle board; veneer veneer particleboard; surface coated particleboard; PVC veneer board and so on.

- Q: Make the raw material of the particleboard

- Can be pre-pressure and hot-pressing treatment. Preload pressure of 0.2 to 2 MPa, with a flat press or roller press.

- Q: Particleboard production process requires proper hot pressing pressure

- and then sawing sanding, inspection packaging. But after the pressure can not heat stacked, otherwise it will increase the sheet brittle.

- Q: Particleboard of the unfavorable factors

- Innovation is the source of enterprise development, business is the main body of innovation activities

- Q: Production of raw materials for particleboard

- Processed into sheet, strip, needle, granular wood, shavings, wood, sawdust, etc., said broken material. I

- Q: Particle shape is the decisive factor in the quality of the particleboard,

- The shavings of the remainder of the woodwork can be reworked as the core of the particleboard

- Q: How to improve the particleboard market space

- we must improve the scale of the project construction, the small particleboard factory to reorganize the small particleboard factory in order to improve the quality of the particleboard and reduce the cost and improve the research and development

Send your message to us

Anti-Moisture Particle Board Moisture Resistant Chipboard

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords