Anodized Aluminum Strips with Structural Aluminum Alloys and Known Isotopes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

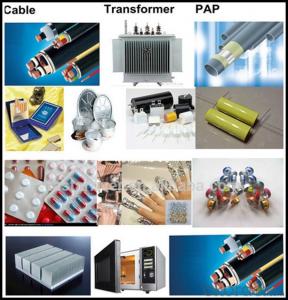

2. Application of Aluminum

(1).Interior: Oil and petrochemical industries...

(2).Exterior: Specialized anti-corrosive applications...

(3).Certain structural retrofit building applications...

3. Feature of Aluminum

In the Earth's crust, aluminium is the most abundant (8.3% by mass) metallic element and the third most abundant of all elements (after oxygen and silicon).The Earth's crust has a higher prevalence of aluminium than the rest of the planet, due to aluminium silicates in the crust. In the Earths mantle, which is only 2% aluminium by mass, these aluminium silicate minerals are largely replaced by silica and magnesium oxides. Overall, the Earth is about 1.4% aluminium by mass (eighth in abundance by mass). In the Earth as a whole, aluminium gains in abundance as compared with the Solar system and Universe, due to Earth's loss of a number of elements which are common in the universe, but which are volatiles at the Earth's distance from the Sun (hydrogen, helium, neon, nitrogen, carbon as hydrocarbon).

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

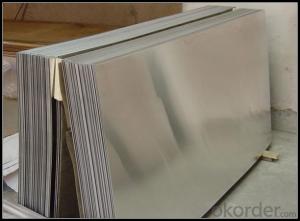

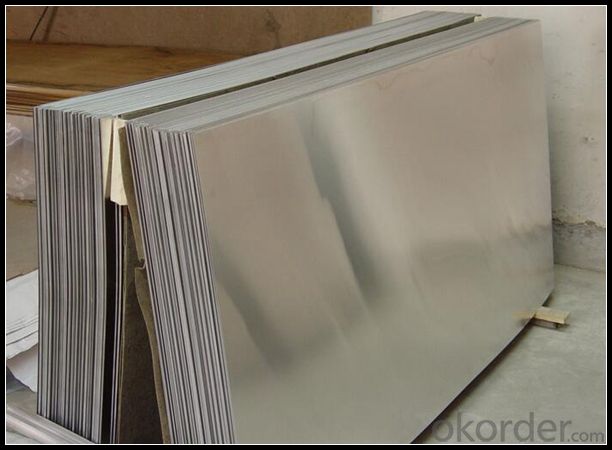

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: What characteristics of aluminum strips make them ideal for construction purposes?

- <p>Aluminum strips are suitable for use in construction due to several key properties. They are lightweight, which reduces the load on structures and makes them easier to handle and install. They possess high strength-to-weight ratio, ensuring durability and resistance to deformation. Aluminum strips are also corrosion-resistant, protecting against rust and other forms of decay, which is crucial for long-term structural integrity. Their excellent thermal conductivity aids in heat management, which is beneficial in both heating and cooling applications. Furthermore, aluminum strips are malleable and can be easily shaped and bent, allowing for versatile design and construction. Lastly, they are recyclable, contributing to sustainability and reducing environmental impact.</p>

- Q: Inquiring about the durability of aluminum strips.

- <p>Aluminum strips are known for their durability. They are resistant to corrosion and weathering, making them suitable for long-term use in various environments. Their strength and light weight also contribute to their durability, allowing them to withstand significant stress without breaking. However, their longevity can be affected by factors such as the quality of the aluminum, the manufacturing process, and the specific conditions they are exposed to. Proper maintenance and handling can further enhance their durability.</p>

- Q: Why should single core cable be armored with aluminium tape?

- Therefore, the aluminum sheath is used to allow magnetic flux to produce an induced current in the aluminum sheath, thereby substantially reducing the magnetic induction of the other external metal parts. The low resistance of the aluminum skin can reduce the heating induced by the induction current

- Q: The question asks if it's possible to use various adhesives or fasteners for installing different kinds of aluminum strips.

- <p>Yes, you can use different types of adhesives or fasteners to install different types of aluminum strips. The choice depends on the application, the weight of the strip, and the surface it's being attached to. For lightweight strips and smooth surfaces, adhesives like double-sided tape or construction adhesive can be effective. For heavier strips or where a more permanent solution is needed, mechanical fasteners such as screws or rivets might be more appropriate. Always consider the strip's weight, the surface material, and the desired longevity of the installation when selecting the type of adhesive or fastener.</p>

- Q: What is the difference between cold rolling and hot rolling of aluminium plate and aluminium strip? Which kind of aluminum plate is good? Speak a little more popularly

- The aluminum plate and the aluminum band are better understood. One is the plate and the other is the coil.

- Q: Can welding of aluminum with water-cooled DC hydrogen arc welding machine how much money

- Cheapest 3 million, slightly better, such as Panasonic's ten thousand or twenty thousand

- Q: This question asks for an overview of the steps involved in the manufacturing of aluminum components used in vehicles.

- <p>The production process of automotive aluminum parts typically involves several key steps: material selection, design, casting or forging, machining, heat treatment, surface treatment, and quality control. Aluminum is chosen for its lightweight and high strength properties. The design phase involves creating detailed plans for the part. Casting or forging shapes the aluminum into rough forms. Machining refines these forms to precise specifications. Heat treatment enhances strength and durability. Surface treatments protect against corrosion and wear. Finally, quality control ensures each part meets industry standards before it is used in vehicles.</p>

- Q: The question asks if it's possible to use aluminum strips as flooring material in kitchen or bathroom areas.

- <p>Aluminum strips can be used for flooring in kitchens and bathrooms, but they are not the most common choice. They are known for their durability, resistance to moisture, and ease of cleaning, which are desirable traits for these areas. However, they can be slippery when wet, making them a less safe option for bathrooms. They also lack the warmth and comfort of other flooring materials, like tiles or wood. For kitchens, aluminum strips can be a good option for their low maintenance and resistance to spills, but they may not provide the aesthetic appeal that many homeowners desire. It's important to consider the specific needs and preferences of your space when choosing flooring materials.</p>

- Q: This question asks for the primary applications or purposes of using aluminum strips.

- <p>Aluminum strips are primarily used in various industries due to their lightweight, corrosion resistance, and high strength-to-weight ratio. They are commonly used in construction for framing and cladding, in the automotive industry for vehicle bodies and parts, in aerospace for aircraft components, and in electrical applications for wiring and conductors. Additionally, aluminum strips are employed in packaging, such as food and beverage cans, and in the manufacturing of electronic devices and heat exchangers. Their versatility makes them a popular choice for many applications where durability and performance are required.</p>

- Q: Is it possible to use aluminum strips for the exterior walls of a building?

- <p>Yes, aluminum strips can be used for exterior walls. They are lightweight, durable, and resistant to corrosion, making them suitable for cladding and facades. Aluminum strips can also be coated with various finishes to enhance their appearance and protect against weathering. They are commonly used in modern architecture for both aesthetic and functional purposes, offering a sleek and contemporary look while providing insulation and weather protection.</p>

Send your message to us

Anodized Aluminum Strips with Structural Aluminum Alloys and Known Isotopes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords